In the realm of sustainable architecture, LEED (Leadership in Energy and Environmental Design) certification has established itself as the gold standard for green building practices. Developed by the U.S. Green Building Council (USGBC) in 1998, LEED provides a comprehensive framework for designing, constructing, and operating environmentally responsible buildings. While LEED can be applied to various building types, laboratories present unique challenges and opportunities for sustainability. Given their intensive energy and resource use, laboratories are prime candidates for green initiatives, which can significantly impact both environmental and operational efficiency.

With high energy demands and complex environmental requirements, laboratories benefit significantly from LEED certification, which can lead to substantial energy savings and improved environmental quality. For instance, laboratories typically consume three to four times more energy per square foot than office buildings, often accounting for a significant portion of a research institution’s energy consumption. By targeting energy use, ventilation, and equipment efficiency via LEED guidelines, laboratories can drastically reduce their carbon footprint while maintaining safety and operational standards.

What is LEED?

LEED aims to transform the way buildings and communities are designed, built, and operated, fostering sustainability through energy-efficient and environmentally conscious practices. By certifying a wide range of building types—from commercial and residential to educational and healthcare—LEED seeks to reduce the environmental impact of the built environment.

The LEED certification process evaluates buildings based on a point system that measures performance across five key areas: sustainable sites, water efficiency, energy and atmosphere, materials and resources, and indoor environmental quality. Buildings can achieve different levels of certification—Certified, Silver, Gold, and Platinum—based on their total points. For laboratories, this process involves specific strategies to address their unique demands, making it possible to achieve high sustainability standards without compromising on research quality or safety.

How the LEED Rating System Works

The LEED rating system offers a comprehensive framework that encourages sustainable building practices. Here’s a step-by-step overview of how it works:

- Registration

Building projects register with USGBC, signifying their intent to pursue LEED certification.

- Select a Rating System

Projects select an appropriate LEED rating system based on their building type. The primary rating systems include:

- LEED for Building Design and Construction (BD+C)

- LEED for Interior Design and Construction (ID+C)

- LEED for Operations and Maintenance (O+M)

- LEED for Neighborhood Development (ND)

- LEED for Cities and Communities

- Credits and Prerequisites

Projects must meet specific prerequisites and can earn credits across several categories, including:

- Sustainable Sites: Minimizing impact on ecosystems and water resources.

- Water Efficiency: Reducing water consumption.

- Energy and Atmosphere: Improving energy performance and integrating renewable energy.

- Materials and Resources: Encouraging the use of sustainable building materials.

- Indoor Environmental Quality: Enhancing the comfort and well-being of occupants.

- Earn Points

Each credit is worth a certain number of points based on its impact on sustainability. By accumulating points through various credits, projects reach different certification levels:

- Certified: 40-49 points

- Silver: 50-59 points

- Gold: 60-79 points

- Platinum: 80+ points

- Submission and Review

After implementing sustainable practices, projects submit documentation for review by Green Business Certification Inc. (GBCI), which awards the appropriate certification level based on the number of points earned.

- Certification

Once the review is complete and the project meets the necessary criteria, it receives official LEED certification.

Continuous Evolution

LEED continues to evolve, with regular updates that align with emerging technologies, new practices, and environmental challenges. LEED-certified buildings stand out because of their positive impact on the environment and also for improving occupant health, reducing operating costs, and enhancing community well-being.

For more information about LEED and how to get your project certified, visit the USGBC website.

LEED Requirements for Wet Lab Space

Overview

Wet lab spaces are specialized environments designed for handling chemicals, drugs, and other substances that necessitate water, direct ventilation, and specialized utilities. They are essential for testing and analyzing a range of materials, so they play an indispensable role in research across scientific disciplines. To ensure safety and compliance with regulatory standards, wet labs adhere to strict guidelines. This comprehensive guide outlines the LEED requirements for wet lab space, covering key attributes, relevant codes, and useful resources.

Space Attributes & Accessibility

- Compliance: Ensure adherence to ABA/Section 504/ADA guidelines.

- Adaptability: Incorporate adjustable furniture and work surfaces, suitable for wheelchair users.

- Equipment: Provide ADA-compliant fume hoods, sinks (34-inch high), and workstations.

- Emergency Fixtures: Install lightweight fire extinguishers, push-up emergency shower handles, and pullout shelves in base cabinets.

Aesthetics

- Materials: Use chemical-resistant surfaces like epoxy paint on walls and seamless vinyl flooring with integral coving for durability. Include low VOC rubber materials to enhance sustainability and reduce emissions.

Functional/Operational

- Separate Laboratory Modules: Each lab module should have independent ventilation and utility connections.

- HVAC Systems: Ensure reliable temperature and humidity control with high-efficiency filtration systems.

- Dust Control: Maintain strict dust control through air barrier systems.

- Utility Services: Provide connections for natural gas, vacuum, pneumatic supply, carbon dioxide, oxygen gas, compressed air or nitrogen, and distilled water.

- Fume Hoods: Each module should include a 5-foot or 6-foot chemical fume hood with direct exhaust and vented acid/corrosive storage cabinets.

- Occupancy: Typically classified under B2, with required fire sprinklers and acoustic controls (Class C1 or C2).

Secure/Safe

- Access Control: Implement secure access control systems.

- Safety Equipment: Install biological safety cabinets (BSCs) for hazardous agents, along with fire extinguishers, eyewash stations, and toxic gas monitors. Biological safety cabinets should also have a low flow alarm.

- Fire and Life Safety: Include fire alarms, audio-visual alerts, and emergency showers in each module.

Sustainability

- Energy Efficiency: Integrate energy-efficient lab equipment and high-efficiency lighting.

- Materials: Use sustainable building materials like recyclable wood and rubber.

- Daylighting: Optimize natural daylighting and maintain indoor air quality.

Relevant Codes and Standards

- NIH/CDC BMBL 5th Edition: Provides guidelines on biosafety levels and hazard containment.

- OSHA: Offers rules for handling hazardous materials.

- International Building Code (IBC): Defines structural requirements and occupancy classifications.

- American National Standards Institute (ANSI): Sets laboratory ventilation standards.

Additional Resources

- WBDG Research Facilities: Offers comprehensive information on research facility design.

- WBDG High-Performance HVAC: Details maintaining optimal lab climate conditions.

- WBDG Sustainable Laboratory Design: Guides incorporating sustainable practices into wet lab design.

As laboratories strive to meet rigorous safety and operational standards, they also face increasing pressure to adopt sustainable practices. While the LEED requirements ensure that wet labs are safe, functional, and compliant with various regulations, the drive for sustainability in laboratory design and operation extends beyond these basic needs. This is where certifications like LEED and the ACT label come into play. Both certifications aim to promote environmental responsibility, but they approach it from different angles and with distinct criteria. Understanding the differences and synergies between LEED certification and the ACT label is crucial for labs seeking to maximize their sustainability impact while maintaining high operational standards.

The Comprehensive Guide to ACT: Enhancing Sustainability in Laboratory Products

In an era where environmental sustainability is at the forefront, the ACT Environmental Impact Factor (EIF) label emerges as a beacon for laboratories worldwide. This comprehensive guide delves into the ACT label, exploring its significance, application, and the transformative impact it holds for the scientific community. From reducing environmental footprints to fostering continuous improvement, the ACT label is at the leading edge of green innovation.

What is the ACT Label?

The ACT (Accountability, Consistency, Transparency) label is an eco-nutrition label designed specifically for laboratory products. Developed by My Green Lab, Corp., a non-profit organization dedicated to promoting sustainability in science, the ACT label provides third-party verified information about the environmental impact of lab products. This label evaluates the entire lifecycle of a product, offering insights into manufacturing practices, energy and water use, packaging, and end-of-life disposal.

The Significance of ACT

ACT stands as the premier eco-label for laboratory products, ensuring that scientists and procurement specialists have access to clear, transparent data regarding the sustainability of their purchases. With more than 1,200 products from more than 30 manufacturers already labeled, ACT’s reach is expanding rapidly, supported by 33 organizations worldwide.

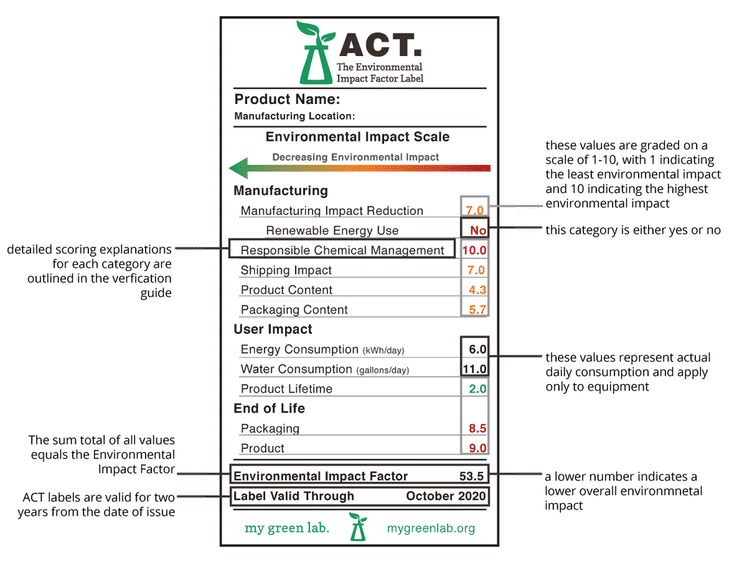

Understanding the ACT Label

The ACT label scores products on a scale of 1 to 10, where 1 represents the lowest environmental impact and 10 the highest. This scoring system covers various aspects:

- Manufacturing Impact: Evaluates reductions in energy, water, and waste during production.

- Energy and Water Consumption: Measures the actual usage of these resources per day.

- Responsible Chemical Management: Assesses the mitigation of hazardous chemicals throughout the product’s lifecycle.

- Packaging and Product Content: Verifies the sustainability of materials used.

Benefits of the ACT Label

Credibility

ACT is recognized as the international gold standard for evaluating laboratory products’ sustainability, offering unparalleled credibility to manufacturers and consumers alike.

Leadership and Market Visibility

Companies using the ACT label showcase their commitment to sustainability, attracting customers, investors, and top talent. This visible commitment also opens doors to new markets through strategic partnerships.

Continuous Improvement

The third-party verification process not only confirms a company’s current sustainability achievements, but also challenges them to continually improve, reducing their overall environmental impact.

Building a Global Green Lab Movement

My Green Lab’s mission extends beyond labeling products: it aims to cultivate a global culture of sustainability in science. Through programs like the My Green Lab Certification and the ACTivist 50, the organization educates and engages scientists and procurement specialists in sustainable practices.

My Green Lab Certification

Endorsed by the UN-backed Race to Zero program, this certification is recognized as the gold standard for laboratory sustainability. Thousands of labs across various sectors have achieved certification, driving significant environmental impact reductions.

The ACTivist 50 and Procurement ACTivist Groups

These groups comprise leading manufacturers and procurement specialists dedicated to promoting sustainable procurement. They collaborate to share best practices and develop guidelines that drive market transformation.

The ACT Label Process

Initial Steps

The ACT label process begins with a kick-off call, followed by data collection and analysis. This involves extensive audits conducted by Sustainable Management and Strategy Collaborative (SMSC) and My Green Lab.

Label Creation and Reporting

Upon completing the audit, a final report is presented, highlighting areas for improvement. Manufacturers receive a detailed ACT label, which is then published on the My Green Lab website.

Annual Review

To maintain the integrity of ACT labels, an annual review process ensures continuous compliance and improvement. This involves regular assessments and re-certifications to capture ongoing advancements in sustainability.

Continuous Improvement for Manufacturers

The ACT label provides external validation and also serves as an internal tool for manufacturers. It establishes a baseline for sustainability efforts and encourages ongoing enhancements. Through periodic updates and stakeholder engagement, the ACT program evolves, reflecting industry advancements and maintaining its relevance.

Conclusion

The ACT label is more than a certification; it is a movement toward a sustainable future in science. By providing transparent, third-party verified information, ACT empowers scientists and procurement specialists to make informed, eco-friendly choices. As the program grows globally, it continues to drive significant environmental improvements in the laboratory product market.

LEED Credits through Water Efficiency with Consolidated’s WaterEco® Series

Achieving LEED certification is a crucial objective for modern, sustainable building projects. One of the key aspects of earning LEED credits is through water efficiency, and Consolidated Sterilizer Systems’s WaterEco® Series provides an innovative solution in this area.

Reducing Water Consumption in Sterilizers

Most modern autoclaves consume significant amounts of water to cool effluent discharge and comply with local building codes, often using up to 1,500 to 1,600 gallons per day. The WaterEco® Series by Consolidated Sterilizer Systems addresses this issue by drastically reducing the water used in autoclave operations.

Key Features of the WaterEco® Series

- WaterEco® Basic: This system collects drainage into a cooling reservoir, using air, previously cooled effluent, and a minimal amount of cold water to cool the effluent.

- WaterEco® Plus: Utilizing a stainless steel heat exchanger and the facility’s chilled water supply, this system virtually eliminates once-through cooling water.

- WaterEco® Vac Plus: Integrated with pre-vacuum autoclaves, this system uses chilled water to cool the vacuum water and exhaust, making it the best solution for minimizing water use.

Benefits of the WaterEco® Systems

- Significant Water Savings: A single eco-friendly autoclave can save more than 60,000 gallons of water annually, translating to a potential cost saving of $100,000 over 15 years based on current utility rates.

- Space-Saving Design: All WaterEco® systems are designed to fit integrally with the sterilizer, conserving valuable laboratory space.

- Easy Retrofit: Both the WaterEco® Basic and WaterEco® Plus can be easily retrofitted onto existing sterilizers, regardless of the manufacturer, ensuring flexibility and ease of implementation.

- Non-Electric Operation: These systems operate without electricity, using a temperature-actuated, non-electric mechanical valve, which further reduces resource consumption and costs.

- Integration with House Chiller Systems: The WaterEco® Plus and WaterEco® Vac Plus can easily integrate with existing house chiller systems, maximizing water savings.

- LEED Eligibility: Installing a WaterEco® system helps architects and builders earn LEED credits by enhancing the building’s water efficiency and sustainability profile.

- Compliance with Building Codes: All WaterEco® systems are designed to meet and exceed building code requirements for effluent discharge temperatures.

Smart Options Available for Consolidated Sterilizers:

- Steam Generators: Offers the ProGEN™ electric steam generator as a steam source when house steam is unavailable.

- Water Saving Systems: Includes WaterEco® systems for eco-friendly and cost-efficient operations.

- Water Purification Systems: Provides Reverse Osmosis or Deionized Water systems for autoclaves.

- SteriNET® Connex™ Remote Connectivity: Enables remote monitoring and data management.

- SterilCARE™ Preventative Maintenance Service Program: A maintenance plan for autoclaves.

- Steril-Q™ Validation and Documentation Services: Supports autoclave validation with IQ/OQ/PQ protocols.

- Rack with Removable Shelving: Offers flexible shelving options.

- Loading Cart & Transfer Carriage: Aids in loading/unloading processes.

- Liquid Ring Pump: Conserves water and reduces cycle time.

- Load Control Probe: Monitors sterilization during cycles.

- Economy Post Vac: Enhances drying time after sterilization.

- Steam/Inlet Filter: Cleans incoming steam.

- Autoclave Chamber Cleaner: Facilitates internal chamber cleaning.

- Data Storage Device: Stores cycle data for analysis and reporting.

Consolidated Sterilizer Systems Earns ACT Label

In addition to water efficiency, Consolidated Sterilizer Systems has earned the ACT label. This label evaluates the environmental impact of laboratory products, allowing facilities to make informed purchasing decisions and advance their sustainability goals.

ACT Label Evaluation Criteria

The ACT label assessment by My Green Labs includes:

- Manufacturing impact

- Renewable energy use

- Responsible chemical management

- Shipping impact

- Product content

- Packaging content

Earning the ACT label involved rigorous testing of autoclaves’ performance, energy and water consumption, and a thorough review of materials, manufacturing processes, and waste disposal practices. The label confirms Consolidated Sterilizer Systems’s commitment to sustainability, publishing independently verified data to help customers evaluate product sustainability.

Conclusion

Incorporating Consolidated Sterilizer Systems’s WaterEco® Series into your facility not only supports sustainable practices by significantly reducing water consumption, but it also aids in achieving valuable LEED credits. These systems offer an effective solution for both new constructions aiming for LEED certification and existing facilities looking to retrofit for better water efficiency and compliance. Additionally, the ACT label highlights the company’s commitment to sustainability, ensuring that its products meet the highest environmental standards. By choosing WaterEco®, you contribute to a greener future while also benefiting from cost savings and operational efficiencies.

Miele Laboratory Washers and ACT Certification

Miele Professional has achieved ACT label certification for three of its glassware washers: the PG 8583, PG 8593, and PG 8583 CD. This certification, awarded by My Green Lab, signifies excellence in sustainability for laboratory equipment. The ACT label provides transparency on environmental impact factors such as energy consumption, water use, and end-of-life considerations.

LEED Credits and Environmental Benefits

Miele’s ACT-certified washers contribute to earning LEED credits. These machines are designed to conserve water, save energy, and reduce emissions, aligning with the principles of sustainable building practices. Key features include:

- Efficient Resource Use: Variable speed pumps with integrated heating elements optimize cleaning performance and resource use.

- Water and Energy Savings: ACT label certification reflects rigorous standards for water and energy conservation, helping labs achieve LEED credits.

- Advanced Features: DI water connection, liquid dispensing, and safety monitoring systems ensure high performance and sustainability.

Gruenberg’s Dry Heat Sterilizers and LEED Accreditation

Gruenberg’s dry heat sterilization technology is an effective and environmentally friendly method for sterilizing laboratory and medical equipment, which aligns well with LEED objectives. By leveraging the advantages of dry heat sterilizers, facilities can potentially earn LEED credits in various categories, contributing to sustainable building operations.

- Energy Efficiency:

- Lower Energy Consumption: Dry heat sterilizers, including those from Gruenberg, use less energy compared to steam sterilizers as they do not require water to generate steam. This efficiency supports the LEED Energy & Atmosphere category, which emphasizes optimizing energy performance and reducing overall energy consumption.

- High-Performance Insulation: Gruenberg’s sterilizers feature high-performance insulation that minimizes heat loss, ensuring efficient use of energy during the sterilization process.

- Water Conservation:

- No Water Usage: Unlike steam sterilizers, Gruenberg’s dry heat sterilizers do not require water for the sterilization process. This significant reduction in water usage supports the LEED Water Efficiency category, aimed at reducing potable water consumption.

- Improved Indoor Environmental Quality:

- No Steam Emissions: Dry heat sterilizers from Gruenberg do not emit steam, reducing the need for complex ventilation systems to manage steam output. This can enhance indoor air quality and support the LEED Indoor Environmental Quality category, which seeks to improve indoor environmental health and comfort.

- Material and Resource Conservation:

- Durable Construction: Gruenberg’s dry heat sterilizers are constructed with robust materials such as 304 stainless steel, ensuring long-term durability and reducing the need for frequent replacements. This durability aligns with the LEED Materials & Resources category, which focuses on the use of sustainable and long-lasting materials.

- Simplified Facility Requirements:

- Ease of Installation: Gruenberg’s dry heat sterilizers often have simpler installation requirements compared to steam sterilizers, because they do not need water supply lines, drains, or steam capture hoods. This simplicity can reduce the need for extensive modifications to the building infrastructure, aligning with LEED goals to minimize the environmental impact of building operations.

- Environmental Responsibility:

- Non-Toxic and Non-Corrosive: Gruenberg’s dry heat sterilizers do not use toxic chemicals, making them an environmentally responsible choice. This characteristic can support various LEED categories aimed at reducing the environmental footprint of building operations.

In conclusion, while dry heat sterilizers offer several benefits that align with LEED objectives, it is essential to consult with a LEED-accredited professional or your architect to ensure that any new equipment qualifies for LEED credits. Specific contributions to LEED accreditation will depend on the overall design and operation of your facility.

Steelco’s Innovative Heat Recovery System for Laboratory Washers

In the quest for energy efficiency and sustainability, Steelco has developed an advanced heat recovery system for their laboratory washers that aligns perfectly with LEED prerequisites. This innovative system not only optimizes energy consumption, but also significantly reduces water usage, making it an exemplary solution for modern laboratories striving for eco-friendly operations.

Key Features:

- Energy Efficiency: Reduces energy consumption by utilizing residual heat from wastewater.

- Water Conservation: Aligns with LEED prerequisites for indoor water use reduction.

- Cost Savings: Lowers operational costs by decreasing energy demands.

- Environmental Responsibility: Minimizes the laboratory’s carbon footprint.

Steelco’s system is ingeniously designed to capture and reuse heat from the wastewater generated during the washing process. At the core of this system is a drain cooling tank equipped with a high-efficiency heat exchanger. When hot wastewater from the washer flows into this cooling tank, it transfers its heat to the incoming cold water that is directed through the heat exchanger. This process effectively preheats the cold water before it is used in the next rinse cycle.

How the System Works:

- Drain Cooling Tank with Heat Exchanger:

- Hot wastewater flows into the cooling tank.

- The heat exchanger transfers heat from the wastewater to the incoming cold water.

- Preheating Incoming Cold Water:

- Cold water is directed through the heat exchanger.

- The system can increase the temperature of the incoming cold water by up to 25 degrees Fahrenheit.

- Energy Savings:

- Preheated water reduces the energy required for subsequent washing cycles.

- This results in lower energy consumption and reduced operational costs.

Beyond energy savings, Steelco’s heat recovery system is meticulously engineered to ensure compliance with LEED prerequisites, particularly concerning indoor water use reduction. A crucial aspect of the system is that it prevents the cooled wastewater from being directly mixed with the outgoing water for immediate discharge. Instead, the heat from the wastewater is efficiently captured and used to preheat the incoming rinse water, ensuring that the system does not rely on once-through water for cooling purposes. This approach not only meets but exceeds LEED’s stringent requirements for sustainable water management.

Compliance and Documentation:

- LEED Prerequisites:

- Ensures the system does not use once-through water for cooling.

- Efficiently captures and reuses heat from wastewater.

- Documentation:

- Detailed process flow diagrams provided.

- Clear illustration of the cold water path through the heat recovery exchanger.

To support their claims and provide transparency, Steelco supplies detailed documentation and process flow diagrams with their systems. These documents clearly illustrate the path of the cold water through the heat recovery exchanger and confirm that it is not blended into the outgoing water, thereby validating the system’s compliance with LEED standards.

In conclusion, Steelco’s heat recovery system stands out as a cutting-edge solution for laboratory washers, embodying the principles of energy efficiency and sustainability. By recovering and reusing heat from wastewater, the system reduces energy demands and conserves water, offering a practical and environmentally responsible choice for laboratories. As facilities continue to seek ways to minimize their environmental impact, Steelco’s innovative system provides a reliable and effective means to achieve their sustainability goals.

Partnering with ARES Scientific for Sustainable Laboratory Solutions

Achieving LEED certification for laboratory design signifies a commitment to energy efficiency and environmental responsibility. Laboratories face unique challenges due to their high energy demands and specialized environmental requirements. By integrating sustainable practices and adhering to LEED standards, laboratories can significantly reduce their environmental footprint while maintaining operational excellence.

ARES Scientific stands out as your specialist for Miele, Consolidated, Gruenberg, and Steelco sales, offering advanced solutions that align with sustainability goals. Miele’s ACT-certified laboratory washers, Consolidated’s WaterEco® Series, Gruenberg’s dry heat sterilizers, and Steelco’s innovative heat recovery systems are prime examples of how state-of-the-art equipment can contribute to LEED certification and overall environmental sustainability. These products help laboratories reduce water and energy consumption, enhance indoor environmental quality, and support compliance with stringent environmental standards.

Choosing ARES Scientific as your partner ensures access to innovative technology and expertise in achieving sustainable laboratory design. Together, we can create laboratory environments that are both efficient and environmentally responsible, paving the way for a greener future in scientific research.