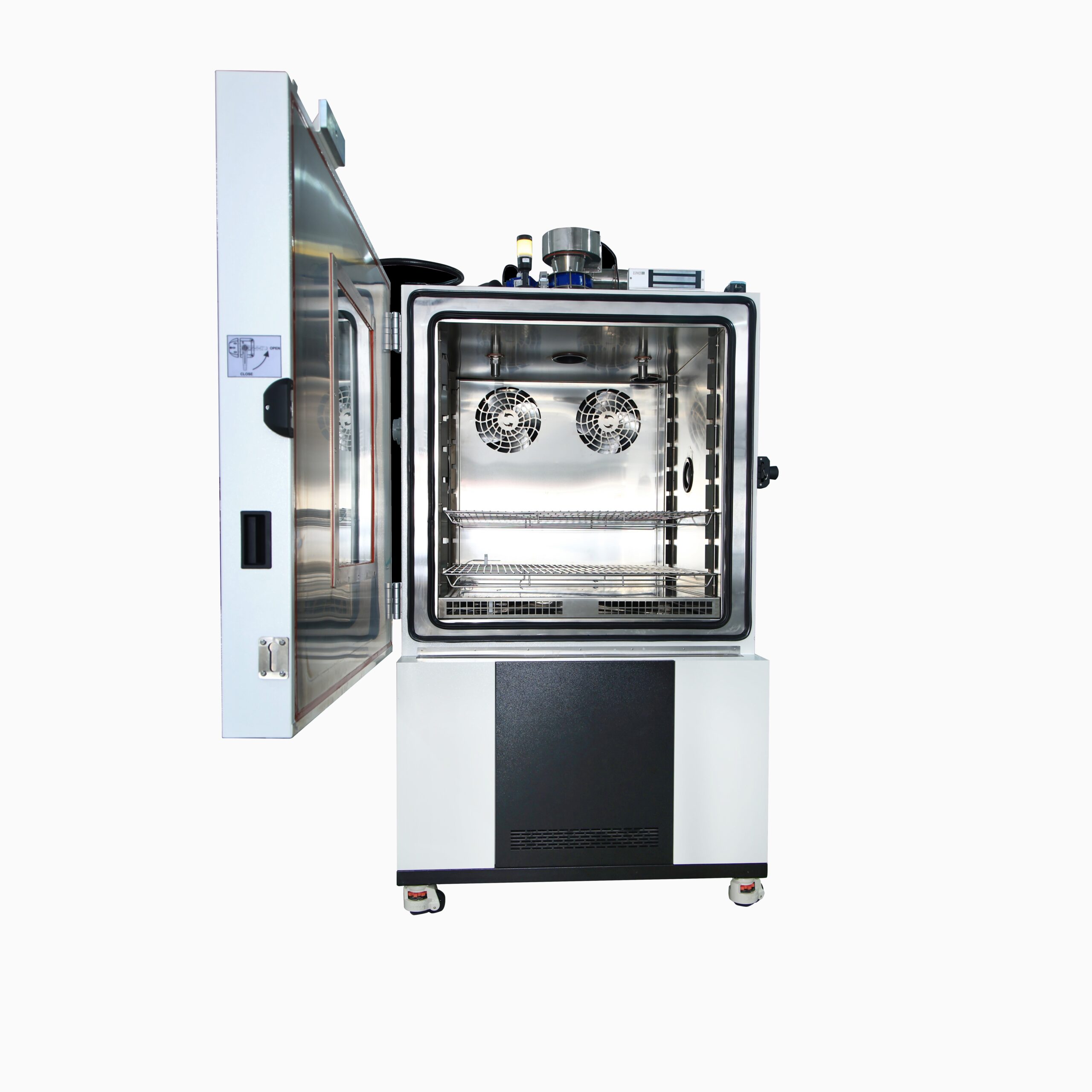

What Is an Environmental Chamber?

An environmental chamber—also called a climatic test chamber, thermal chamber, or environmental temperature chamber—is a controlled system that replicates real-world conditions like temperature, humidity, and pressure. These environmental test chambers are essential tools in research and product development, helping engineers predict product performance under variable environmental stresses.

Common Test Profiles & Why They Matter

Modern test chambers are designed for multiple testing applications such as thermal cycling, humidity control, and stability testing. Each profile simulates specific environmental stress factors—like rapid temperature changes or high humidity—to ensure that materials and assemblies can withstand real-world operating conditions. Many climatic chambers are programmable to alternate between hot, cold, and humid environments for long-duration stress testing.

Industry Use-Cases

Environmental test chambers are used across industries, including electronics, automotive, aerospace, pharmaceuticals, and biotechnology. For example, thermal chambers are vital for electronic component durability testing, while climatic test chambers are used for package integrity and material performance validation. Manufacturers rely on these chambers to meet strict international testing standards such as IEC 60068 and MIL-STD-810.

Selection Guide: How to Pick the Right Chamber

When selecting a custom environmental chamber, key considerations include size, temperature range, humidity control, ramp rate, and accuracy. Work with an environmental chamber manufacturer to match your chamber’s specifications to your test protocols. For complex testing scenarios, environmental chamber manufacturers offer fully customizable options, including multi-zone control, altitude simulation, and vibration integration.

Validation, Compliance & Data Integrity

Most regulated industries require chambers to undergo IQ/OQ/PQ validation. Environmental test chambers must be calibrated for temperature uniformity and humidity accuracy. Leading climatic chamber manufacturers integrate data logging systems with audit trails to ensure compliance with standards such as 21 CFR Part 11 and ISO 9001.

Sustainability & Total Cost of Ownership

Today’s environmental test chambers feature energy-efficient compressors, LED lighting, and EC motors that reduce power consumption. Manufacturers are increasingly focusing on low-GWP refrigerants and sustainable production to lower environmental impact without compromising chamber performance.

Chamber Type Comparison

| Type | Best For | Pros | Considerations |

|---|---|---|---|

| Climatic (Temp + RH) | Electronics, packaging, coatings | Most versatile; humidity control | More maintenance (humidifier/defrost) |

| Thermal-Only | Metals, composites | Simpler, faster ramps | No humidity acceleration |

| Walk-In / Stability Rooms | Long-term storage/life testing | High capacity; steady states | Requires dedicated utilities |

| Custom Environmental Chambers | Specialized R&D | Tailored to unique test requirements | Higher design lead time |

Buyer’s Checklist

- Confirm operating range for your environmental test chamber.

- Evaluate climatic chamber manufacturer credentials and support.

- Check uniformity, accuracy, and recovery times.

- Ensure controller supports advanced logging and alarms.

- Consider long-term service and calibration plans.

- Specify custom features (e.g., dual-zone environment chamber control).

Frequently Asked Questions

What is an environmental test chamber used for?

An environmental test chamber simulates temperature and humidity variations to test material durability, electronics reliability, and product stability in controlled conditions.

What’s the difference between a thermal and climatic test chamber?

A thermal chamber controls temperature alone, while a climatic test chamber manages both temperature and humidity, allowing more complex environmental simulations.

How do environmental chambers maintain accuracy?

Environmental chambers use PID controllers, calibrated sensors, and insulated enclosures to ensure precise temperature and humidity regulation.

Can I order custom environmental chambers?

Yes. Leading environmental chamber manufacturers offer custom solutions for specialized industries like aerospace, biotech, and energy testing.

How long do environmental test chambers last?

With proper maintenance, a high-quality environmental test chamber can operate for 10–15 years or longer.

Who are the top climatic chamber manufacturers?

Top global climatic chamber manufacturers include Thermotron, Espec, CSZ, and Weiss Technik, all known for reliability and precision.

Are environmental chambers expensive to run?

Energy-efficient environmental test chambers reduce operating costs through advanced insulation and compressor optimization.

How often should chambers be calibrated?

Most environmental temperature chambers should be calibrated every 6–12 months, depending on usage and regulatory requirements.

What industries use environmental test chambers?

Common industries include automotive, aerospace, pharmaceutical, materials science, and electronics manufacturing.

Where can I buy a reliable environmental test chamber?

You can purchase environmental test chambers through ARES Scientific, offering access to leading environmental chamber manufacturers and expert consultation for your application.

Contact ARES Scientific

Looking for custom environmental chambers from trusted climatic chamber manufacturers? Contact ARES Scientific today for expert guidance, pricing, and lead times.