Description

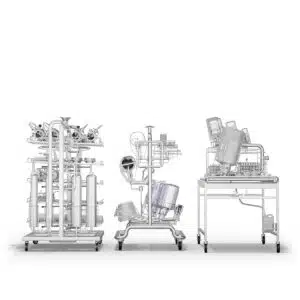

• Compact Size & GMP Compliance: Preserve valuable GMP manufacturing space with the smallest available footprint in a pharma-grade washer.

• Versatile Configuration: Available in single or passthrough double door options with a hinged full glass door, accommodating your facility’s unique layout.

• Self-Cleaning Design: Minimize cross-contamination risk with a design that ensures self-cleaning of the machine chamber and pipework at each process stage.

• Pharma Industry Compliant Heating Elements: Made from AISI 316L (1.4404) stainless steel and electro-polished, ensuring sanitary and dead leg free operation.

• Connection Options: Choose between Steam heat exchanger or Electrical heat exchanger versions for seamless integration with your plant’s infrastructure.

• Thorough Drying: Complete drying of items, both internally and externally, with variable temperature control and inline HEPA filtration for optimal air quality.

• cGMP Compliance: Designed, manufactured, validated, and documented in accordance with the latest global practices and standards.

• Remote Assistance: On-board VPN router enables remote support without on-site visits, reducing support costs and improving machine uptime.

• Easy Maintenance: Accessible components and electrical cabinet from the loading side for efficient servicing.

• Non-Proprietary Parts: Built with globally available components, allowing for convenient sourcing of spare parts from Steelco or original equipment manufacturers.