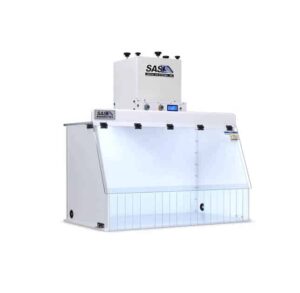

Ductless Fume Hoods for Flexible Chemical Vapor Filtration Without External Ducting

Ductless fume hoods provide chemical vapor containment and operator protection through self-contained filtration systems, eliminating the need for external exhaust ducting, facility modifications, or costly HVAC integration. These portable containment enclosures use activated carbon filters, HEPA filters, or specialty media to capture and neutralize chemical vapors, particulates, and fumes directly at the source, making them ideal for laboratories with limited infrastructure, temporary workspaces, or facilities where traditional ducted fume hoods are impractical or cost-prohibitive.

Modern ductless laboratory fume hoods incorporate advanced filtration technology, real-time airflow monitoring, and ergonomic designs suited to chemistry labs, pharmaceutical compounding, forensics, educational institutions, and research facilities. At ARES Scientific, our ductless hood portfolio includes basic models for light-duty applications, deluxe systems with enhanced monitoring capabilities, and advanced units featuring automated controls and comprehensive safety features. For applications requiring 100% external exhaust or high-volume chemical processing, explore our ducted fume hood solutions.

Common Applications for Ductless Fume Hoods in Laboratory Environments

- Analytical Chemistry: Sample preparation, chromatography, spectroscopy, and routine chemical analysis where volatile organic compounds (VOCs) or low-concentration solvents are used

- Pharmaceutical Compounding: Non-hazardous drug preparation, powder weighing, and pharmacy workflows requiring localized containment without facility exhaust modification

- Forensic Science: Evidence processing, chemical reagent handling, fingerprint development, and trace analysis in crime labs and field investigation units

- Educational Laboratories: High school and university chemistry labs conducting demonstrations, experiments, and student training with common laboratory chemicals and solvents

- Quality Control Testing: Industrial QA/QC labs performing product testing, material analysis, and benchtop analytical procedures with minimal chemical exposure

- Research & Development: Small-scale synthesis, formulation development, and exploratory chemistry in cGMP laboratories or pilot facilities

- Mobile or Temporary Labs: Field testing stations, temporary research sites, or mobile laboratory units requiring portable chemical containment solutions

- Electronic Repair & Soldering: Flux fume extraction, solder smoke capture, and electronics assembly work requiring localized vapor removal

Types of Ductless Fume Hood Systems: Choosing the Right Model

Basic Model Ductless Fume Hoods

Entry-level ductless hoods feature variable speed controllers, acrylic or polycarbonate construction, and primary carbon or HEPA filtration. Designed for educational settings, light-duty chemistry, and budget-conscious facilities, basic models provide essential operator protection for low-volume solvent work, powder weighing, and routine laboratory tasks. These systems typically include manual airflow adjustment, basic viewing windows, and straightforward filter replacement procedures without digital monitoring capabilities.

Deluxe Model Ductless Fume Hoods

Mid-tier ductless systems incorporate adjustable LED lighting, upgraded viewing windows, pressure monitoring gauges, and hour counters to track filter lifespan and maintenance intervals. Deluxe models suit analytical laboratories, compounding pharmacies, and facilities requiring enhanced operator visibility, improved ergonomics, and basic performance tracking. These hoods often feature improved sealing, better airflow distribution, and compatibility with a wider range of filter media for diverse chemical applications.

Advanced Model Ductless Fume Hoods

Premium ductless fume hood systems feature automated airflow control (Auto Sentry), real-time average airflow display, environmental condition monitoring (temperature and humidity), accumulated filter usage tracking, and alarm functions for maintenance alerts. Advanced models are engineered for high-volume analytical labs, cGMP pharmaceutical facilities, and regulated environments requiring documented performance verification and comprehensive safety features. These systems typically include carbon steel construction, enhanced filtration capacity, and integration capabilities with facility monitoring systems.

How to Choose the Right Ductless Fume Hood for Your Laboratory

- Chemical Compatibility: Verify that available filter media (activated carbon, HEPA, specialty adsorbents) effectively capture the specific chemicals, solvents, and vapors used in your applications; consult filter charts and manufacturer compatibility guides

- Airflow Requirements: Evaluate face velocity specifications (typically 80–100 ft/min), work zone dimensions, and filter saturation indicators to ensure adequate containment for your workflow volume and chemical concentrations

- Monitoring and Documentation Needs: Consider whether your facility requires real-time airflow monitoring, filter usage tracking, alarm systems, or compliance documentation for regulatory audits or cGMP validation

- Workspace Configuration: Assess hood width (commonly 24", 36", 48"), depth, and portability requirements based on available benchtop space, equipment footprint, and potential relocation needs

- Filter Lifecycle and Operating Costs: Calculate total cost of ownership including filter replacement frequency, filter media pricing, and maintenance requirements based on chemical usage patterns and operating hours

- Safety Features and Ergonomics: Look for features such as adjustable sash height, interior LED lighting, hinged access panels, viewing window quality, and safety interlocks that enhance operator comfort during extended use

- Facility Limitations: Confirm that ductless operation aligns with facility capabilities, building codes, and environmental permits; some jurisdictions require room ventilation or air quality monitoring even with ductless systems

- Alternative Solutions: For high-toxicity chemicals, volatile compounds exceeding filter capacity, or applications requiring 100% exhaust, consider ducted fume hoods or biological safety cabinets instead

Key Features to Compare When Evaluating Ductless Fume Hood Systems

- Multi-Stage Filtration Technology: Advanced carbon/HEPA filter combinations capture both particulates and chemical vapors, protecting operators from respiratory exposure while maintaining clean recirculated air quality

- Real-Time Airflow Monitoring: Digital displays and alarm systems provide continuous verification of containment performance, ensuring safe operation and timely filter replacement for consistent protection

- Energy Efficiency and Portability: Self-contained design eliminates HVAC exhaust requirements, reduces facility energy costs, and allows flexible positioning or relocation without expensive ductwork modifications

- Rapid Deployment and Installation: Plug-and-play operation enables same-day setup without construction permits, contractor coordination, or building modifications, ideal for temporary labs or rapid facility expansion

- Customizable Filter Media Options: Interchangeable filter cartridges accommodate diverse chemical classes including acids, bases, solvents, formaldehyde, and mercury vapors through application-specific adsorbent selections

- Ergonomic Work Zone Design: Optimized viewing angles, adjustable LED task lighting, and interior power outlets enhance visibility and workspace functionality for precise laboratory procedures

- Compact Footprint Solutions: Space-efficient designs maximize benchtop utilization in crowded laboratories while maintaining adequate work zone dimensions for standard equipment and procedures

- Environmental Responsibility: Filter-based containment eliminates facility exhaust emissions, reduces environmental impact, and simplifies compliance with air quality regulations compared to traditional ducted systems

- Maintenance Accessibility: Tool-free filter access, clear replacement indicators, and straightforward service procedures minimize downtime and support in-house maintenance capabilities

Ductless Fume Hood Maintenance Best Practices and Filter Management

- Monitor Filter Saturation: Track filter usage hours, pressure differential readings, or manufacturer-recommended replacement intervals based on chemical type and usage volume; replace filters proactively before breakthrough occurs

- Document Filter Changes: Maintain detailed logs of filter installation dates, chemical exposures, airflow readings, and replacement schedules to support safety programs and regulatory compliance requirements

- Verify Airflow Performance: Conduct routine face velocity measurements using calibrated anemometers or smoke tests to confirm containment effectiveness, typically quarterly or after filter replacement

- Clean Work Surfaces Regularly: Wipe down interior surfaces, viewing windows, and sash assemblies with compatible cleaning agents to prevent cross-contamination and maintain visibility during procedures

- Inspect Seals and Gaskets: Check filter housing seals, sash gaskets, and access panel closures for wear or damage that could compromise containment integrity or allow bypass airflow

- Calibrate Monitoring Systems: For advanced models, verify accuracy of pressure gauges, hour counters, airflow sensors, and alarm functions according to manufacturer specifications or facility protocols

- Store Replacement Filters Properly: Maintain adequate inventory of application-specific filter media in controlled storage conditions to prevent deterioration and ensure availability when needed

- Dispose of Saturated Filters Safely: Follow hazardous waste protocols for contaminated filter disposal, consulting local regulations and decontamination requirements for chemical-laden media

- Review Chemical Compatibility: Periodically reassess chemical inventory against filter media capabilities, especially when introducing new solvents, reagents, or procedures to laboratory workflows

- Provide Operator Training: Ensure all users understand proper hood operation, filter limitations, emergency procedures, and the importance of reporting unusual odors or airflow issues immediately

Frequently Asked Questions About Ductless Fume Hoods

How do ductless fume hoods differ from traditional ducted fume hoods?

Ductless fume hoods use internal filtration (carbon and HEPA filters) to remove chemical vapors and recirculate filtered air back into the laboratory, while ducted fume hoods exhaust contaminated air directly outside the building through dedicated ductwork. Ductless systems offer portability, lower installation costs, and energy efficiency but are limited to compatible chemicals and require diligent filter maintenance. Ducted hoods provide 100% exhaust for high-toxicity applications but require facility infrastructure and HVAC integration.

What types of chemicals can I safely use in a ductless fume hood?

Chemical compatibility depends entirely on the installed filter media. Standard activated carbon filters effectively capture many organic solvents (acetone, methanol, toluene), while specialty filters can address formaldehyde, acids, bases, or mercury vapors. Always consult manufacturer filter charts and safety data sheets (SDS) to verify compatibility. Highly toxic, carcinogenic, or extremely volatile compounds typically require ducted exhaust systems instead of ductless filtration.

How often do I need to replace ductless fume hood filters?

Filter lifespan varies significantly based on chemical type, concentration, usage frequency, and filter capacity. Light-duty applications might achieve 6-12 months of service, while high-volume solvent work may require quarterly replacement. Advanced models with hour counters and saturation indicators help predict replacement timing. Maintain a replacement schedule based on manufacturer guidelines, actual usage data, and periodic face velocity testing to prevent filter breakthrough and ensure continuous protection.

Do ductless fume hoods require annual certification like ducted hoods?

While not always legally mandated like ducted hood certification, regular performance verification is strongly recommended for ductless systems. Best practice includes quarterly face velocity measurements, filter integrity checks, and documentation of maintenance activities. Regulated facilities such as cGMP laboratories or compounding pharmacies often implement formal testing protocols equivalent to annual certification to demonstrate operator protection and equipment performance.

Can ductless fume hoods be used for powder weighing or particulate work?

Yes, ductless hoods equipped with HEPA filtration effectively contain powders, particulates, and aerosols generated during weighing, mixing, or material handling. HEPA filters capture 99.97% of particles ≥0.3 microns, making these systems suitable for pharmaceutical powder compounding, chemical reagent handling, and laboratory procedures generating dust or particulates. For weighing highly toxic powders or potent pharmaceutical compounds, consider dedicated vented balance enclosures or containment isolators for enhanced protection.

Are ductless fume hoods portable and easy to relocate?

Most ductless fume hoods are designed for portability and require only standard electrical connections (typically 110V or 220V). Without external ductwork constraints, these units can be easily repositioned, moved between laboratories, or relocated during facility renovations with minimal disruption. This flexibility makes ductless systems ideal for temporary research projects, shared equipment facilities, educational laboratories with evolving space requirements, or organizations anticipating facility changes. Always verify electrical compatibility and ensure adequate room ventilation when relocating equipment.

Do I still need room ventilation with a ductless fume hood?

Yes, adequate room ventilation remains important even with ductless fume hoods. While filtered air is recirculated rather than exhausted, proper laboratory air exchange rates (typically 6-12 air changes per hour) help maintain overall air quality, prevent heat buildup, and provide backup protection in case of filter failure or breakthrough. Some building codes and safety regulations require minimum ventilation rates regardless of containment equipment type. Consult your facility's safety officer, building codes, and environmental monitoring requirements to ensure comprehensive air quality management.

Related Containment and Laboratory Safety Equipment

Comprehensive laboratory safety often requires multiple containment solutions tailored to specific applications. Explore these complementary equipment categories:

- Ducted Fume Hoods – For high-volume chemical work, highly toxic substances, or applications requiring 100% external exhaust

- Biological Safety Cabinets – HEPA-filtered containment for biohazardous materials, cell culture, and infectious agent handling

- Vented Balance Enclosures – Specialized containment for powder weighing, potent compound handling, and precise analytical procedures

- Clean Benches – HEPA-filtered workstations providing product protection for sterile assembly, electronics, and precision work

- Environmental Monitoring Systems – Real-time air quality verification, particle counting, and compliance documentation equipment

- Compounding Aseptic Containment Isolators (CACI) – For sterile hazardous drug compounding in pharmacy applications

- Decontamination Systems – Surface and environmental decontamination solutions for laboratory safety and equipment maintenance

- View All Clean Air & Containment Solutions – Complete portfolio of laboratory containment and air quality equipment

Request a Quote for Ductless Fume Hood Systems

ARES Scientific provides expert consultation, competitive pricing, and comprehensive support for ductless fume hood selection and implementation. Our team helps you evaluate chemical compatibility, determine appropriate filtration requirements, calculate total cost of ownership, and ensure your containment solution meets safety requirements and operational needs.

Contact our clean air specialists today:

Whether you're establishing a new laboratory, upgrading existing equipment, or expanding research capabilities, ARES Scientific delivers the ductless fume hood technology, filtration expertise, and ongoing support you need for safe, compliant, and efficient chemical vapor containment.