ARES Scientific is an Authorized Distributor of automated cage wash systems engineered to support high-throughput vivarium operations, barrier facilities, and research environments where sanitation, repeatability, and operational efficiency are critical. Automated cage wash systems form the backbone of modern animal care facilities by enabling validated cleaning and thermal disinfection of cages, racks, bottles, and accessories while reducing labor variability and ergonomic strain. ARES Scientific works directly with academic institutions, pharmaceutical and biotechnology companies, and contract research organizations to specify, supply, and support these systems as part of fully integrated cage wash and material flow solutions.

As an Authorized Distributor, ARES Scientific provides direct access to proven automated cage wash technologies along with consultative guidance to ensure each system aligns with facility capacity, workflow requirements, and long-term operational goals. Our role extends beyond equipment supply to include early-stage planning, utility coordination, space optimization, and post-installation support, ensuring consistent performance throughout the lifecycle of the system.

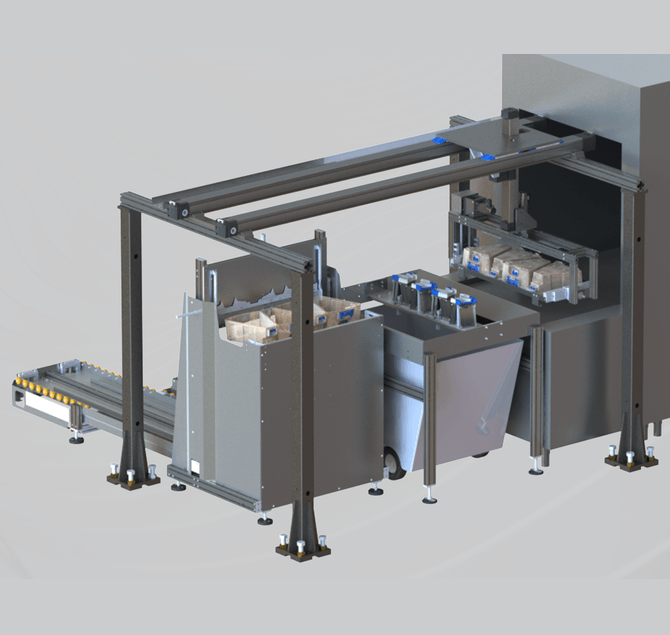

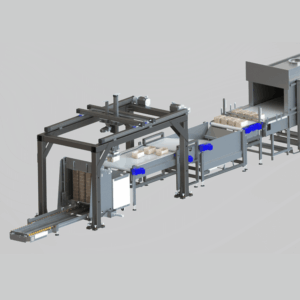

Automated cage wash systems are designed to handle the demanding throughput requirements of laboratory animal facilities where hundreds to thousands of cages may be processed daily. These systems utilize programmable wash cycles, high-pressure spray arms, controlled detergent dosing, and validated thermal disinfection to achieve repeatable, documented cleaning outcomes. They are commonly deployed in rodent vivariums, large animal research facilities, and centralized cage wash suites supporting multiple animal rooms or entire research buildings.

Primary users of automated cage wash systems include vivarium managers, animal care technicians, facilities engineers, and research support teams responsible for maintaining biosecurity and operational continuity. When evaluating automated cage wash solutions, facilities must balance throughput needs, cage compatibility, available utilities, and spatial constraints while ensuring compliance with internal animal care standards and institutional protocols.

Key Buying Considerations for Automated Cage Wash Systems

Selecting the appropriate automated cage wash system requires careful evaluation of both operational and facility-specific factors. Throughput requirements are often the starting point, as cage volume directly influences washer size, chamber configuration, and cycle programming. Facilities must account for peak usage periods, future growth, and redundancy needs when determining system capacity.

Thermal disinfection capability is another critical consideration. Automated cage wash systems rely on precise temperature control and exposure times to achieve effective microbial reduction. Consistency across wash loads is essential for maintaining animal welfare standards and minimizing the risk of cross-contamination. Facilities should also consider cage material compatibility, as different plastics and metals respond differently to heat, detergents, and mechanical action.

Utility availability plays a major role in system selection. Automated cage wash systems may require high-capacity water supply, steam, electrical service, and appropriate drainage. Early coordination with facilities and engineering teams helps prevent costly retrofits and ensures seamless integration into existing infrastructure. Space planning, including clean and dirty side separation, is equally important to support efficient workflow and compliance with facility protocols.

Automated Cage Wash System Categories

ARES Scientific supplies a comprehensive range of automated cage wash solutions designed to meet the operational demands of modern vivarium facilities. Within the washers and dryers portfolio, automated cage wash systems are often specified alongside complementary equipment to create cohesive washroom workflows.

Facilities frequently deploy automated cage wash systems in conjunction with

cage rack and bottle washers to accommodate varying load sizes and accessory types. This layered approach allows facilities to process both full racks and smaller components efficiently without compromising throughput.

For aquatic research programs, specialized

zebrafish and aquatics washers support cleaning requirements unique to tanks, racks, and aquatic housing systems. These washers are engineered to protect delicate components while delivering consistent cleaning performance.

Automated cage wash systems are also commonly paired with

cage wash racks and baskets, which improve loading efficiency, protect equipment during wash cycles, and help standardize workflows across operators and shifts.

Supported Manufacturers

ARES Scientific partners with established manufacturers of automated cage wash systems known for durability, validated performance, and long-term serviceability. As an Authorized Distributor, ARES Scientific works closely with manufacturers to ensure customers receive properly specified systems that align with facility requirements, operational expectations, and institutional standards.

Automated cage wash solutions from

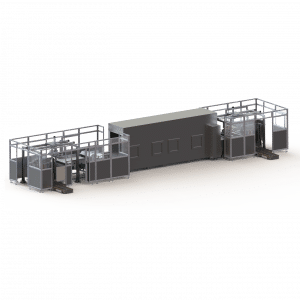

Steelco are widely used in research vivariums for their configurable wash programs, robust stainless steel construction, and compatibility with a broad range of cage formats. These systems are often selected for facilities requiring high throughput and flexible cycle customization.

Facilities seeking integrated cage washing and drying workflows frequently consider systems from

Miele, which are designed to support consistent thermal disinfection and efficient processing in high-volume environments. ARES Scientific also supports installations that incorporate material handling infrastructure from manufacturers such as

Lenderking, particularly where transport efficiency and ergonomic optimization are priorities.

Related Equipment and Integrated Washroom Solutions

Automated cage wash systems deliver the greatest value when deployed as part of a coordinated washroom and vivarium workflow. ARES Scientific supports cross-category solutions that enhance efficiency, safety, and long-term scalability.

Many facilities integrate automated cage wash systems with

cage change and transfer stations to maintain clean-to-dirty separation and support barrier protocols. These stations help preserve sanitation downstream of the wash process and protect animal rooms from contamination risk.

Material flow is further optimized through the use of

material handling equipment, which reduces manual transport, improves operator safety, and supports consistent throughput. Facilities managing high cage volumes often rely on

bulk trucks to efficiently move cages, racks, and accessories between animal rooms and wash areas.

In applications requiring additional sterilization steps, automated cage wash systems are frequently paired with

vivarium dry heat sterilizers to support validated processing of components that require higher temperature exposure.

Why Buy Automated Cage Wash Systems from ARES Scientific

ARES Scientific does more than supply automated cage wash equipment. As an Authorized Distributor, we act as a technical partner throughout the planning, procurement, and implementation process. Our team works directly with customers to evaluate throughput targets, facility constraints, and workflow requirements to ensure each system is properly specified.

ARES Scientific provides application consultation, assists with equipment layouts and utility coordination, and supports specification documentation for institutional review. During procurement, we coordinate with manufacturers to align lead times, installation requirements, and commissioning support. After installation, we remain engaged to support training coordination, service planning, and long-term operational continuity.

Supporting Efficient and Compliant Vivarium Operations

Automated cage wash systems are a foundational component of efficient, compliant animal research facilities. When properly specified and integrated, they support consistent sanitation, protect animal welfare, and reduce operational variability. By partnering with ARES Scientific, facilities gain access to proven equipment, authorized manufacturer support, and experienced application guidance.

Whether planning a new vivarium, expanding cage wash capacity, or upgrading an existing washroom, ARES Scientific provides the expertise and authorized access needed to support successful outcomes. For quotes, technical guidance, or project-specific support related to automated cage wash systems, contact ARES Scientific to work with an experienced equipment specialist.