High-Capacity Laboratory Glassware Washers for Demanding Research Environments

When daily throughput demands exceed standard capacity, large capacity laboratory washers become essential infrastructure for busy research facilities. These high-volume glassware cleaning systems handle the rigorous demands of centralized washing facilities, multi-lab operations, and production environments where hundreds of items require daily processing. From pharmaceutical manufacturing to high-throughput academic research, freestanding laboratory washers deliver the cleaning power and efficiency that keep your facility running at peak productivity.

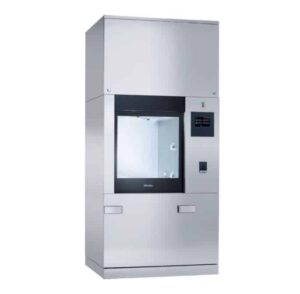

Unlike compact undercounter laboratory washers, large capacity models feature spacious chambers with multiple washing levels and flexible rack configurations. These robust systems process everything from standard beakers and flasks to oversized carboys and specialized equipment—often completing cycles for 200+ pieces simultaneously. With advanced injection washing technology on up to six levels, these floor-standing units maximize vertical space while minimizing footprint requirements.

Why Centralized Washing Facilities Choose Large Capacity Systems

High-throughput laboratories face a critical challenge: maintaining contamination-free glassware without creating workflow bottlenecks. Large capacity glassware washers solve this problem through superior chamber volume and intelligent automation. Research facilities serving multiple departments benefit from centralized washing operations that consolidate equipment, reduce redundancy, and maintain consistent cleaning standards across all laboratories.

These professional-grade systems incorporate HEPA-filtered forced air drying, programmable cycle options, and advanced water treatment capabilities. Many models feature dual drying systems that circulate heated air through both chamber and injectors, ensuring complete moisture removal from narrow-neck glassware and complex geometries. For GMP environments and pharmaceutical applications, optional validation protocols including IQ/OQ/PQ documentation provide the quality assurance required by regulatory agencies.

Modern glassware washers optimize resource consumption through variable-speed circulation pumps that automatically adjust pressure and flow rates based on load requirements. This intelligent approach reduces water usage by up to 40% compared to conventional systems while delivering superior cleaning results. Pre-heating tanks accelerate cycle times to under 40 minutes, enabling facilities to process more loads per shift without compromising cleaning efficacy.

Critical Features That Define High-Performance Washers

The best large capacity lab washers share several distinguishing characteristics. Stainless steel construction throughout the chamber, sump, and spray arms ensures chemical resistance and durability when processing aggressive laboratory residues. Telescopic bearing rails on all levels facilitate ergonomic loading and unloading, while motorized sliding doors optimize access in space-constrained environments.

Flexible rack positioning represents another crucial advantage. Chamber configurations adapt to accommodate varying item heights—from compact pipettes to 100-liter carboys—through adjustable level systems with multiple connection points. This versatility eliminates the need for multiple specialized washers, consolidating equipment investment while maintaining processing capability across diverse glassware types. Premium models offer up to eight possible rack locations within the same chamber.

Temperature control capabilities extend from ambient to 95°C, with precise holding times that support everything from gentle cleaning to thermal disinfection. Programmable cycle parameters allow customization for specific contamination types, from light soiling to baked-on residues. For sensitive applications requiring deionized water or conductivity monitoring, advanced models integrate these systems directly into the washing process.

Selecting the Right Capacity for Your Laboratory

Determining appropriate washer capacity requires careful analysis of daily processing volumes and peak demand periods. Facilities processing 150-300 pieces per day typically benefit from mid-range freestanding models with three washing levels. Operations exceeding 400 pieces daily, or those serving multiple departments, should consider high-capacity units offering four or more levels with chamber volumes approaching 500 liters.

Consider future expansion when specifying equipment. Many research facilities underestimate growth trajectories, leading to premature capacity constraints. Selecting a system with 25-30% excess capacity provides operational flexibility and prevents the costly disruption of mid-term equipment replacement. Pass-through double-door configurations prove particularly valuable for segregating clean and dirty zones in controlled environments.

Integration with existing infrastructure matters significantly. Evaluate available electrical configurations (208V, 240V, or steam-heated options), water quality requirements, and facility drainage capacity. Some facilities benefit from on-board water softeners to protect sensitive glassware and extend equipment life in areas with hard water. Others require specialized exhaust management for steam-heated models or enhanced ventilation for high-temperature drying cycles.

Maximizing Return on Equipment Investment

Large capacity laboratory washers represent substantial capital expenditures, yet their long-term value extends far beyond cleaning capability. Automated washing eliminates the labor costs, reproducibility issues, and safety concerns associated with manual cleaning. One facility calculated annual savings exceeding $45,000 through reduced technician time, decreased consumable costs, and eliminated waste disposal fees for single-use alternatives.

Energy efficiency improvements in modern systems further enhance ROI. Look for features like delay-start programming that shifts operation to off-peak utility hours, variable-speed pumps that reduce electrical consumption, and insulated chambers that minimize heat loss. Some models achieve energy reductions of 30-50% compared to previous generations while maintaining superior cleaning performance. Consult our guide on selecting the best features for a laboratory glassware washer for detailed efficiency considerations.

Reliability directly impacts total cost of ownership. Dual-filter systems protect circulation pumps from debris-related damage, while high-grade stainless steel construction resists corrosion from aggressive chemicals. Selecting manufacturers with established service networks ensures access to preventative maintenance programs and rapid response for unexpected issues. Many facilities implement comprehensive maintenance schedules that extend equipment lifespan beyond 15 years.

Advanced Technologies Reshaping Laboratory Washing

Innovation continues transforming large capacity washer capabilities. Digital PLC controllers with touchscreen interfaces now offer 40-65 programmable cycle options, enabling precise customization for specific applications. These systems maintain detailed process records including temperature profiles, cycle duration, and chemical dosing—critical documentation for regulated environments and quality management systems.

Injection washing technology has evolved significantly, with modern systems featuring individual spray nozzles for each vessel. This direct-contact approach delivers superior cleaning compared to overhead spray arms alone, particularly for narrow-neck glassware and complex shapes. Some premium models combine injection washing on multiple levels with chamber spray arms, ensuring comprehensive coverage regardless of item geometry or loading configuration.

Drying performance represents another area of substantial advancement. HEPA 14-filtered forced air systems guarantee contaminant-free drying while adjustable temperature and duration settings accommodate heat-sensitive materials. Dual drying paths—simultaneously delivering heated air through chamber outlets and injector nozzles—complete the process in significantly less time than passive drying methods. This accelerated approach increases daily throughput and reduces cycle times by 25-40%.

Detergent Systems and Chemical Management

Proper detergent selection and delivery critically impact cleaning results. Large capacity systems typically feature integrated peristaltic pumps that precisely dose alkaline cleaners, acid neutralizers, and rinse additives based on programmable parameters. This automated approach eliminates manual handling, improves consistency, and reduces chemical waste through exact dispensing.

On-board chemical storage represents a significant convenience feature, with many models accommodating containers up to 10 liters within accessible compartments. This eliminates the need for remote tank locations while simplifying inventory management and reducing handling requirements. For comprehensive guidance on chemical selection, review our complete guide to laboratory glassware washer detergents.

Water quality management extends chemical system performance. Pre-heating tanks enable final rinses with deionized or purified water, critical for trace analysis and sensitive applications. Optional conductivity sensors monitor rinse water quality in real-time, automatically extending cycles if specifications aren't met. Flow meters provide redundancy for chemical dosing control, ensuring consistent results across thousands of cycles.

Compliance and Validation Requirements

Pharmaceutical, clinical, and GMP laboratories face stringent documentation requirements for cleaning equipment. Large capacity washers designed for these environments offer comprehensive validation packages including installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) protocols. Electronic signature capabilities, audit trails, and user management systems ensure 21 CFR Part 11 compliance where required.

Process monitoring extends beyond basic temperature and time tracking. Advanced systems record parameters including water conductivity, detergent concentration, spray pressure, and chamber humidity throughout each cycle phase. This granular data supports root cause analysis when results deviate from specifications and demonstrates process control during regulatory audits.

For facilities handling hazardous compounds or infectious materials, pass-through double-door configurations with interlocking systems prevent cross-contamination between classified areas. These barrier washers maintain separate clean and dirty zones, supporting proper workflow segregation in BSL-2, BSL-3, and pharmaceutical manufacturing environments. Discover additional containment solutions in our clean air and containment category.

Integration with Laboratory Infrastructure

Large capacity washers function as central components within comprehensive laboratory ecosystems. Coordinating equipment specifications with broader facility requirements ensures optimal performance and prevents integration challenges. Steam-heated models require adequate steam capacity and pressure, while electrically-heated systems demand appropriate circuit ratings and voltage configurations.

Drainage infrastructure represents a frequently overlooked consideration. High-volume systems discharge substantial water quantities during drain cycles, necessitating appropriately sized drainage lines and floor drain capacity. Poor drainage design leads to equipment alarms, incomplete cycles, and potential facility damage. Facilities should verify drain line diameter, slope, and capacity before installation.

Ventilation requirements vary based on system design and operational parameters. Steam-heated models and high-temperature drying cycles generate considerable moisture that must be managed through adequate exhaust capacity or dedicated steam condensing systems. Space planning should account for service access, loading ergonomics, and integration with material handling systems including laboratory carts and transport equipment.

Training and Operational Excellence

Maximizing large capacity washer performance requires comprehensive operator training and standardized operating procedures. Understanding optimal loading techniques, appropriate cycle selection, and proper rack configuration prevents common issues including inadequate cleaning, extended cycle times, and premature equipment wear. Many manufacturers offer detailed training programs and operational support during commissioning.

Implementing preventative maintenance schedules protects equipment investment and ensures consistent performance. Regular tasks include filter cleaning, spray arm inspection, door seal examination, and chemical system verification. Our detailed article on 15 pro tips to extend lab glassware washer lifespan provides actionable guidance for maintenance programs.

Performance verification through periodic testing maintains confidence in cleaning results. Simple protocols including visual inspection, water break tests, and periodic residue analysis confirm that systems continue meeting specifications. For critical applications, implementing quality control programs with documented verification prevents costly failures and regulatory findings.

Exploring Your Large Capacity Washer Options

The right large capacity laboratory washer transforms your facility's productivity while delivering the cleaning consistency that research demands. From compact three-level systems suitable for growing programs to industrial-scale units processing thousands of items weekly, selecting appropriate capacity and features requires careful consideration of current needs and future growth.

Our team brings extensive experience specifying and implementing laboratory washing solutions across diverse applications. We partner with leading manufacturers to provide systems featuring the latest injection washing technology, advanced drying capabilities, and comprehensive validation support. Whether you're establishing a centralized washing facility, replacing aging equipment, or expanding capacity, we'll help identify the optimal solution for your requirements.

Discover complementary equipment including laboratory sterilizers and autoclaves that integrate seamlessly with washing operations. For cannabis research and production facilities, explore our specialized cannabis equipment solutions. Contact us today to discuss your large capacity laboratory washer requirements and receive expert guidance on selecting the perfect system for your facility.