- Shop Products

- Animal/Vivarium Equipment & Supplies

- Anesthesia Systems

- Animal Transport

- Animal Watering

- Automated Cage Wash Systems

- Bedding Fill and Disposal Systems

- Bulk Trucks

- Cage Change and Transfer Stations

- Cage, Rack and Bottle Washers

- Dry Heat Sterilizers

- Euthanasia Systems

- Ferret Caging

- Large Animal Caging

- Isolators

- Marmoset Caging

- Material Handling

- Necropsy Tables and Procedure Hoods

- Procedure Lights

- Rabbit Caging

- Rodent Caging

- Steam Sterilizers

- Tree Shrew Caging

- Vivarium Dry Heat Sterilizers

- Zebrafish and Aquatics Washers

- Benchtop Instruments

- Cannabis Processing

- Clean Air & Containment

- Cold Storage

- Decontamination

- Environmental Monitoring

- Environmental Test Chambers

- cGMP

- Incubators

- Ovens

- Pathology & Mortuary Equipment

- Personal Protective Equipment

- Sterilizers and Autoclaves

- Tables, Storage and Carts

- Washers and Dryers

- X-Rays and Irradiators

- Animal/Vivarium Equipment & Supplies

- Featured

- Industries

- Manufacturers

- Animal Care Systems

- Avante Animal Health

- Baker

- Benchmark Scientific

- Caron Scientific

- Consolidated Sterilizer Systems

- Corepoint Scientific

- DeNovix

- Envisys

- Euthanex

- Flow Sciences, Inc.

- Gruenberg

- Haier

- Hettich

- KUBTEC Scientific

- Lenderking

- Metro

- Miele

- Mopec

- Mortech Manufacturing

- Ohaus

- Park Bio

- SE Lab Group Inc.

- Sentry Air Systems

- SPOT Imaging

- Steelco

- Sychem

- TOMI Environmental Solutions, Inc.

- Visron

- Resources

- About

- Contact

- Quote

Environmental Test Chambers

Environmental Test Chambers: Accelerated Testing for Product Development and Quality Assurance

Environmental test chambers simulate real-world environmental conditions under controlled laboratory settings, enabling manufacturers, research institutions, and quality control laboratories to evaluate product performance, durability, and reliability across temperature extremes, humidity variations, thermal cycling, and environmental stressors. These precision-engineered systems accelerate product lifecycle testing that would otherwise require months or years of field exposure, allowing engineers to identify design weaknesses, validate material selections, verify regulatory compliance, and optimize product specifications before commercial release. From automotive components and consumer electronics to pharmaceutical packaging and renewable energy systems, environmental testing chambers provide the empirical data necessary to ensure product quality, reduce warranty costs, and meet international testing standards.

ARES Scientific delivers a comprehensive portfolio of environmental test chambers designed for diverse testing protocols across industries including automotive, aerospace, electronics, energy, pharmaceuticals, and materials science. Our range includes temperature stability chambers, temperature-humidity-light chambers, thermal shock systems, battery testing chambers with safety containment, and specialized chambers for corrosion testing, ingress protection verification, and photovoltaic performance evaluation. Each system features precise environmental control, comprehensive data logging, programmable cycling capabilities, and options for custom configurations to match specific testing standards including MIL-STD, IEC, ASTM, ISO, and SAE specifications.

Common Applications for Environmental Test Chambers

- Product Development and R&D Testing: Evaluating prototype performance under extreme conditions, accelerated aging studies, material characterization, and design validation before production tooling investment

- Quality Control and Incoming Inspection: Verifying component specifications, supplier qualification testing, production lot sampling, and compliance verification against purchase order requirements

- Reliability and Life Testing: Highly Accelerated Life Testing (HALT), Highly Accelerated Stress Screening (HASS), Mean Time Between Failures (MTBF) determination, and warranty prediction modeling

- Regulatory Compliance Testing: Meeting automotive standards (AEC-Q100, SAE), military specifications (MIL-STD-810), telecommunications requirements (GR-63-CORE), medical device standards (IEC 60601), and consumer safety testing

- Materials Science Research: Polymer aging studies, adhesive bond strength evaluation, composite material characterization, coating durability assessment, and failure mode analysis

- Electronics and Semiconductor Testing: Temperature cycling for solder joint reliability, burn-in testing, thermal management validation, power electronics qualification, and IC package testing

- Pharmaceutical and Medical Device Validation: Packaging integrity testing, accelerated stability studies, shipping validation, sterilization process validation, and medical device biocompatibility under environmental stress

- Renewable Energy Component Testing: Solar panel performance under varied irradiance and temperature, wind turbine component durability, battery system thermal management, and energy storage device cycling

Types of Environmental Test Chambers: Comprehensive Testing Solutions

Environmental test chambers are categorized by the environmental parameters controlled and the specific testing protocols they support:

Temperature and Humidity Chambers

Temperature-humidity chambers provide independent control of temperature (typically -70°C to +180°C) and relative humidity (10% to 98% RH), enabling testing to standards including IEC 60068-2-1, IEC 60068-2-2, and MIL-STD-810 Method 507. These versatile chambers support constant climate testing, cyclic temperature-humidity profiles, condensation testing, and combined environmental stress screening. Applications include electronics reliability testing, packaging validation, pharmaceutical stability studies, and automotive component qualification. Advanced models integrate with light sources for photostability testing per ICH Q1B guidelines.

Temperature Stability and Cycling Chambers

Temperature stability chambers deliver precise temperature uniformity (±0.5°C or better) across the work volume, critical for calibration laboratories, pharmaceutical stability testing, and materials research requiring tight temperature control. Thermal cycling chambers alternate between temperature extremes with programmable ramp rates, soak times, and cycle counts to evaluate solder joint integrity, material expansion/contraction compatibility, and thermal fatigue resistance per JEDEC JESD22-A104 and IEC 60068-2-14 standards.

Thermal Shock Test Chambers

Thermal shock chambers subject test specimens to rapid temperature transitions (up to 30°C per minute) by transferring samples between hot and cold zones or using liquid nitrogen injection for extreme rate changes. This aggressive testing method identifies brittle fracture susceptibility, material compatibility issues, and assembly failures caused by differential thermal expansion. Two-zone and three-zone configurations accommodate various test specimen sizes and transition speed requirements for aerospace, automotive, and military electronics applications meeting MIL-STD-810 Method 503.

Battery Testing Chambers with Safety Systems

Battery testing chambers incorporate specialized safety features including explosion-proof construction, thermal runaway containment, smoke detection, oxygen monitoring, and fire suppression systems. These chambers support lithium-ion battery testing per UN 38.3, UL 1642, UL 2054, IEC 62133, and SAE J2464 standards, enabling altitude simulation, temperature cycling, vibration testing, and abuse condition evaluation while protecting personnel and facilities from thermal runaway events. Critical for electric vehicle battery development, consumer electronics qualification, and energy storage system validation.

Corrosion and Environmental Exposure Chambers

Salt spray chambers generate controlled corrosive fog per ASTM B117, ISO 9227, and other standards to evaluate coating performance, material corrosion resistance, and protective finish durability. Complementary testing includes rain test chambers simulating water ingress per IPX testing requirements, sand and dust chambers for ingress protection verification to IP5X/IP6X standards, and combined corrosion-humidity chambers for accelerated degradation studies.

Solar Panel and Photovoltaic Testing Chambers

Solar panel testing chambers combine temperature control, humidity regulation, and programmable solar irradiance simulation to evaluate photovoltaic module performance per IEC 61215, IEC 61646, and UL 1703 standards. These specialized chambers support damp heat testing (85°C/85% RH for 1000 hours), thermal cycling (-40°C to +85°C), humidity-freeze testing, and UV exposure evaluation critical for solar panel certification and long-term performance prediction.

Specialized Testing Equipment

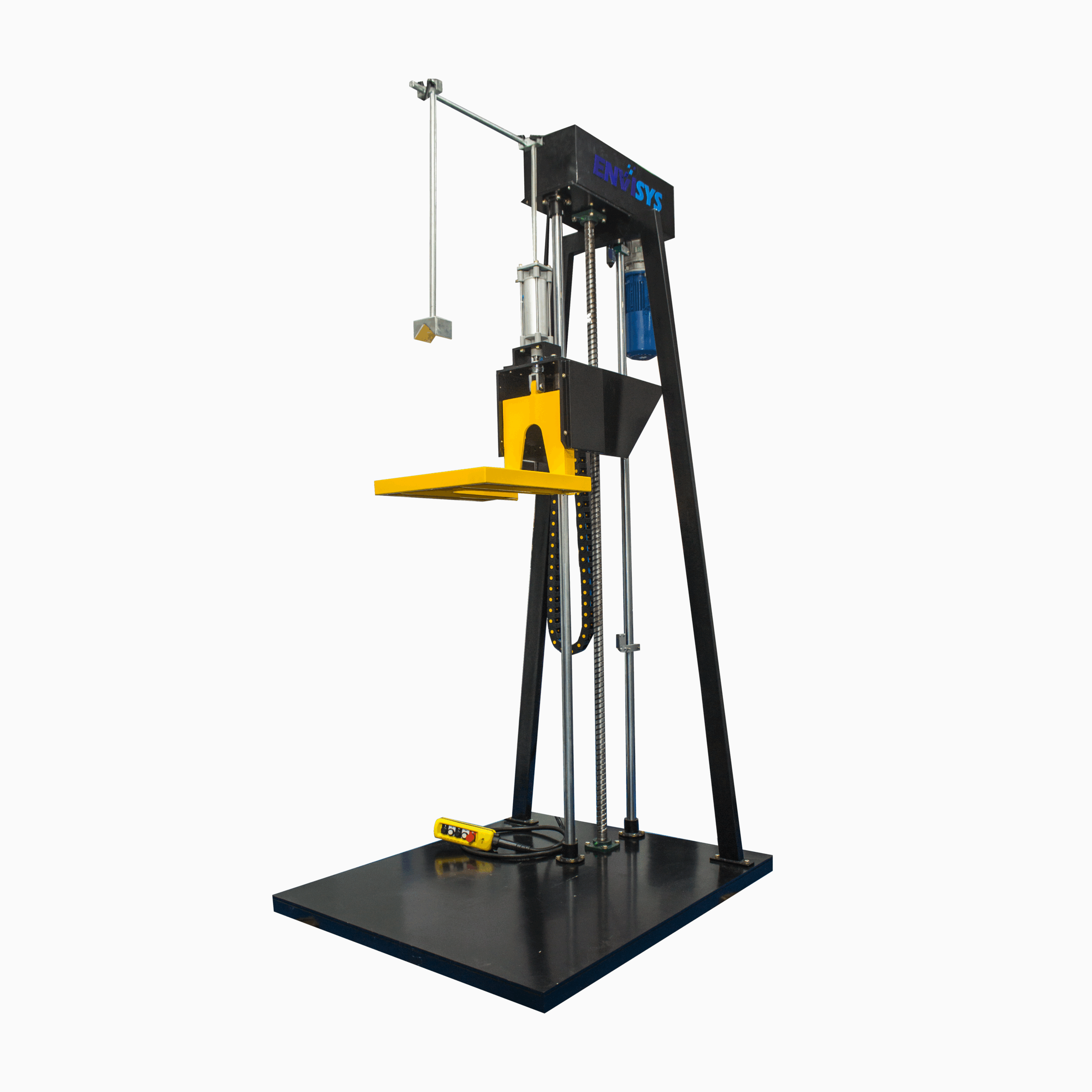

Drop testing machines simulate shipping and handling impacts, evaluating packaging effectiveness and product fragility per ASTM D5276 and ISTA procedures. Walk-in chambers accommodate large assemblies including automotive interiors, aerospace components, and industrial equipment requiring whole-unit environmental testing.

How to Choose the Right Environmental Test Chamber: Critical Decision Factors

- Testing Standards and Protocols: Identify applicable industry standards (MIL-STD-810, IEC 60068, JEDEC, ASTM, SAE) and specific test methods required; ensure chamber capabilities match standard temperature ranges, humidity levels, cycling rates, and test duration requirements

- Temperature Range and Performance: Specify minimum and maximum temperature requirements with adequate margin; evaluate temperature uniformity throughout work space (±2°C typical, ±0.5°C for precision applications), ramp rates for thermal cycling, and recovery time after door openings

- Humidity Control Requirements: Determine if humidity control is required and the necessary range; assess whether condensation testing, freeze-thaw cycling, or low-humidity conditions are needed; verify humidity control accuracy (±3% RH typical) across temperature range

- Chamber Size and Work Volume: Calculate internal dimensions needed for test specimens plus clearance for airflow; consider whether benchtop (20-100L), floor-standing (200-1000L), or walk-in chambers best accommodate testing needs and allow for future growth

- Programmability and Control Sophistication: Evaluate programming capability for complex profiles with multiple segments, ramps, and loops; assess data logging features, remote monitoring options, alarm systems, and integration with laboratory information management systems (LIMS)

- Safety and Containment Features: For battery testing or hazardous materials, verify explosion-proof ratings, ventilation systems, fire suppression capability, and emergency shutdown functions; ensure compliance with NFPA and OSHA requirements

- Energy Efficiency and Operating Costs: Compare electrical power requirements, refrigeration efficiency, and estimated annual operating costs; evaluate insulation quality, standby power consumption, and refrigerant environmental impact

- Validation and Documentation: For regulated industries (pharmaceutical, medical device, aerospace), ensure chamber includes IQ/OQ documentation packages, calibration certificates traceable to national standards, and qualification test reports

Key Features to Compare in Environmental Test Chambers

- Advanced Refrigeration Systems: Cascade refrigeration for ultra-low temperatures (-70°C to -80°C), adaptive refrigeration adjusting to load conditions, environmentally friendly refrigerants (R-23, R-508B alternatives), and rapid pulldown capabilities minimizing test time

- Precision Control and Uniformity: PID microprocessor control with auto-tuning, multiple zone temperature monitoring, forced-air circulation systems ensuring uniformity, and independent over-temperature protection preventing specimen damage

- Humidity Generation Technologies: Evaporative pan systems for standard applications, boiler-type steam generators for rapid response, atomizing spray humidification for precise control, and automatic water level management with low-water alarms

- Data Acquisition and Connectivity: Built-in data loggers with USB/Ethernet export, wireless monitoring via smartphone apps, real-time graphing, alarm notification via email/SMS, and 21 CFR Part 11 compliance for pharmaceutical applications

- Chamber Construction and Durability: Stainless steel interior chambers resisting corrosion, double-wall construction with foam insulation, reinforced flooring for heavy test loads, and viewing windows with heated glass preventing condensation

- User-Friendly Programming: Touchscreen interfaces with intuitive navigation, pre-programmed standard test profiles (MIL-STD, IEC), custom profile creation with graphical editors, and program library storage for frequently used protocols

- Safety and Compliance Features: Automatic door locks during operation, emergency stop buttons, independent safety controllers, low-temperature alarms, and construction meeting UL, CSA, CE, and other safety standards

- Service and Accessibility: Front-serviceable components for ease of maintenance, removable side panels for major service access, standard replacement parts availability, and diagnostic software for troubleshooting

Understanding Key Testing Standards

Environmental test chambers support compliance with numerous industry standards. Common specifications include:

| Standard | Industry | Key Requirements |

|---|---|---|

| MIL-STD-810 | Military/Defense | Temperature extremes, altitude, humidity, thermal shock, vibration |

| IEC 60068 | Electronics | Environmental testing methods including temperature, humidity, vibration |

| JEDEC JESD22 | Semiconductors | Temperature cycling, moisture sensitivity, board-level reliability |

| ASTM D4169 | Packaging | Shipping container testing, vibration, drop, compression |

| SAE J1455 | Automotive | Electronic component environmental testing procedures |

| ICH Q1A(R2) | Pharmaceutical | Stability testing protocols for drug products |

| IEC 61215 | Solar/PV | Crystalline silicon photovoltaic module qualification |

| UN 38.3 | Battery/Transport | Lithium battery transport safety testing requirements |

Consult our technical team to ensure chamber specifications align with your specific testing standard requirements and acceptance criteria.

Maintenance Best Practices and Performance Optimization

- Weekly Operational Checks: Inspect door gaskets for proper seal, verify drain lines are clear, check humidity water reservoir levels, review temperature and humidity uniformity across chamber volume, and clean any moisture accumulation

- Monthly Preventive Maintenance: Clean condenser coils removing dust and debris, inspect refrigeration line connections for leaks, test all alarms and safety interlocks, clean interior chamber surfaces, and verify accurate sensor readings against reference thermometer

- Quarterly Service Activities: Replace air filters (if equipped), inspect and clean circulation fans, check door hinges and latches for wear, test over-temperature protection systems, and verify data logger accuracy and time synchronization

- Annual Professional Calibration: Engage factory-trained technicians for comprehensive calibration of temperature and humidity sensors, pressure transducers, and control systems against NIST-traceable standards; document uniformity surveys per IEST-RP-CC006; update calibration certificates and validation records

- Refrigeration System Care: Monitor refrigerant charge levels, inspect compressor operation for unusual noise or vibration, verify proper oil levels in compressor systems, and schedule refrigerant recovery if leaks detected

- Water Quality Management: Use deionized or distilled water for humidity systems preventing mineral buildup, implement weekly water reservoir cleaning for biological growth prevention, and replace water supply filters per manufacturer schedules

- Documentation and Compliance: Maintain usage logs tracking chamber operation hours and test profiles, document all maintenance activities with dates and technician signatures, archive calibration certificates, and retain validation documentation for regulatory audits

Integration with Testing Workflows

Environmental test chambers function as part of comprehensive testing programs. Integrate chambers with complementary equipment for complete product validation: centrifuges for mechanical stress testing, vibration shakers for combined environment testing, precision balances for pre/post-test measurements, and ultra-low temperature freezers for specimen conditioning. For pharmaceutical applications, combine environmental chambers with incubators for microbiological stability testing and environmental monitoring systems for continuous validation documentation.

Frequently Asked Questions About Environmental Test Chambers

What is the difference between a temperature chamber and a temperature-humidity chamber?

A: Temperature-only chambers control temperature across a specified range without humidity regulation, suitable for thermal cycling, burn-in testing, and applications where moisture control is unnecessary. Temperature-humidity chambers add independent humidity control (typically 10-98% RH), enabling testing per standards requiring combined temperature-moisture stress such as IEC 60068-2-38 or pharmaceutical ICH guidelines. Temperature-humidity chambers cost more due to additional humidification/dehumidification systems but provide greater testing flexibility for most applications.

How accurate are environmental test chambers?

A: Temperature accuracy typically ranges from ±0.5°C to ±2.0°C depending on chamber quality and setpoint. Temperature uniformity across the work volume is typically ±1°C to ±3°C when empty and ±2°C to ±5°C with test loads. Humidity control accuracy is generally ±3% to ±5% RH. High-precision chambers for calibration or pharmaceutical applications achieve ±0.3°C temperature accuracy and ±1.5% RH humidity control. Accuracy should be verified through regular calibration against NIST-traceable standards and documented per ISO/IEC 17025 requirements.

What size environmental chamber do I need?

A: Chamber interior dimensions should accommodate test specimens with adequate clearance for airflow circulation—typically 15-20cm (6-8 inches) on all sides. Consider the largest item requiring testing plus growth for future needs. Benchtop chambers (20-100L) suit electronics components and small assemblies. Floor-standing chambers (200-1000L) accommodate larger products and multiple simultaneous tests. Walk-in chambers (2000L+) are required for whole-unit testing of automotive interiors, aerospace assemblies, or large industrial equipment. Undersizing chambers compromises temperature uniformity and test validity.

How fast can environmental chambers change temperature?

A: Temperature change rates vary significantly by chamber design and temperature range. Standard chambers typically achieve 1-3°C per minute. High-performance rapid-rate chambers reach 5-10°C per minute. Thermal shock systems deliver 15-30°C per minute or faster using liquid nitrogen injection or rapid transfer between temperature zones. Actual rates depend on starting temperature, target temperature, chamber thermal mass, and test specimen heat capacity. Heating is typically faster than cooling due to refrigeration system limitations.

Do environmental chambers require special installation?

A: Most chambers require three-phase electrical power (208/230/460VAC), adequate floor loading capacity (verify with structural engineer for large units), climate-controlled laboratory space, and adequate clearance for service access (typically 60-90cm on sides and rear). Humidity-capable chambers need water supply (softened or deionized recommended) and drainage. Walk-in chambers may require facility modifications including reinforced flooring, dedicated HVAC, and utility rough-in. Battery test chambers require additional ventilation for safety. Consult factory representatives for site preparation requirements specific to your model.

Can environmental chambers be validated for pharmaceutical use?

A: Yes. Chambers used for pharmaceutical stability testing or medical device validation require Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) per ICH guidelines and 21 CFR Part 11 for electronic records. Validation includes mapping temperature and humidity uniformity throughout work volume (typically 9-point minimum), documenting empty chamber performance, and conducting loaded chamber studies simulating actual use conditions. Our chambers include pre-written IQ/OQ protocols, NIST-traceable calibration certificates, and optional data systems with electronic signatures and audit trails supporting regulatory compliance.

What maintenance do environmental chambers require?

A: Routine maintenance includes weekly door gasket inspection and drain line verification, monthly condenser coil cleaning and interior chamber cleaning, quarterly air filter replacement and circulation fan inspection, and annual professional calibration with NIST-traceable temperature and humidity sensor verification. Refrigeration systems require periodic refrigerant charge verification and compressor oil level checks. Humidity systems need regular water reservoir cleaning (weekly) and water quality management using deionized or distilled water. Documented maintenance programs extend equipment life and ensure test result validity. Budget 2-4 hours quarterly for routine maintenance plus annual professional calibration (4-8 hours).

Industry-Specific Applications and Case Studies

For detailed guidance on environmental testing applications, review our comprehensive environmental test chambers applications guide covering automotive electronics testing, solar panel qualification protocols, battery safety evaluation, and pharmaceutical stability programs. Our testing specialists provide consultative support for test protocol development, chamber specification, standard interpretation, and validation strategy to ensure your environmental testing program meets regulatory requirements and produces actionable reliability data.

Related Testing and Quality Control Equipment

Complete your testing laboratory with complementary instrumentation and equipment:

- Battery Testing Chambers – Specialized safety systems for lithium-ion battery evaluation

- Thermal Shock Chambers – Rapid temperature transition testing for material compatibility

- Salt Spray Chambers – Corrosion resistance evaluation per ASTM B117 and ISO 9227

- Precision Balances – Pre/post-test weighing and measurement documentation

- Moisture Analyzers – Material moisture content determination before/after environmental exposure

- Ultra-Low Temperature Freezers – Specimen conditioning and long-term storage at -80°C

- Laboratory Incubators – Biological stability testing and microbiological evaluation

- Laboratory Ovens – Thermal aging, baking, and drying applications

Request a Quote for Environmental Test Chambers

Our environmental testing equipment specialists support R&D laboratories, quality control departments, testing services, automotive manufacturers, electronics companies, and renewable energy developers in selecting chambers that meet testing standards, accommodate specimen sizes, and fit within capital budgets. We provide comprehensive project support including test protocol review, chamber specification development, site assessment, installation coordination, operator training, and validation services for regulated industries.

Contact ARES Scientific to discuss your environmental testing requirements. Request detailed quotations with technical specifications, schedule virtual or on-site product demonstrations, or consult with our applications engineers about test method optimization, standard compliance, and chamber configuration options. We serve customers throughout the United States with factory-direct pricing, professional installation services, and ongoing technical support.