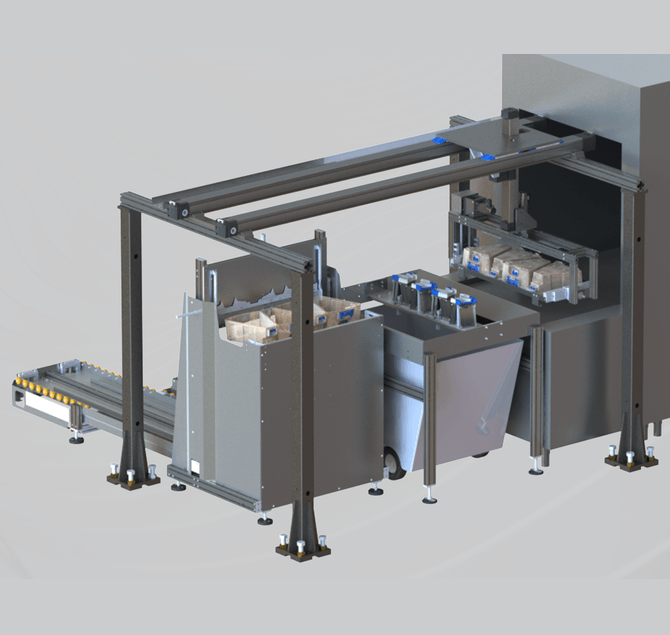

Visron Automated Cage Handling System 240

Quote

The VACH 240 by Visron Automation is an economical automated cage handling system designed to replace manual cage scraping and bedding processes. Prioritizing size and affordability over speed, it efficiently processes up to 500 cages per hour. The system features multi-cage compatibility through modular components, a row-based pass-through mechanism that prevents workflow interruptions, and customizable cage flipping options to suit specific facility needs. Ideal for laboratories seeking to enhance efficiency and reduce labor costs, the VACH 240 offers a cost-effective solution without compromising performance.

Description

• Cost-Effective Automation: Provides an affordable solution for automating cage handling processes.

• High Throughput: Processes up to 500 cages per hour, enhancing operational efficiency.

• Multi-Cage Compatibility: Accommodates various cage types through interchangeable modular components.

• Uninterrupted Workflow: Row-based pass-through system advances unruly cages to a holding bin, preventing system stoppages.

• Customizable Flipping Mechanism: Offers active or gravity flip options tailored to facility requirements.

• Flexible Bedding Options: Supports different bedding materials to meet specific laboratory needs.

• Space-Saving Design: Compact footprint suitable for laboratories with limited space.

• Labor Reduction: Automates manual tasks, reducing staffing needs and associated costs.

• User-Friendly Operation: Designed for ease of use, minimizing training time for personnel.

• Durable Construction: Built with robust materials to ensure long-lasting performance in demanding environments.

• Processing Speed: Up to 500 cages per hour.

• Cage Compatibility: Supports multiple cage types via modular components.

• Pass-Through System: Row-based mechanism with holding bin for unruly cages.

• Flipping Mechanism: Customizable active or gravity flip options.

• Bedding System: Flexible options to accommodate various bedding materials.

• Queue System: No infeed or outfeed queue required.

• Technician Requirement: Operable by a single technician.

• Customization: Adaptable to specific facility layouts and needs.

• Construction: Durable materials designed for longevity in laboratory settings.

• Maintenance: Engineered for easy maintenance and minimal downtime.