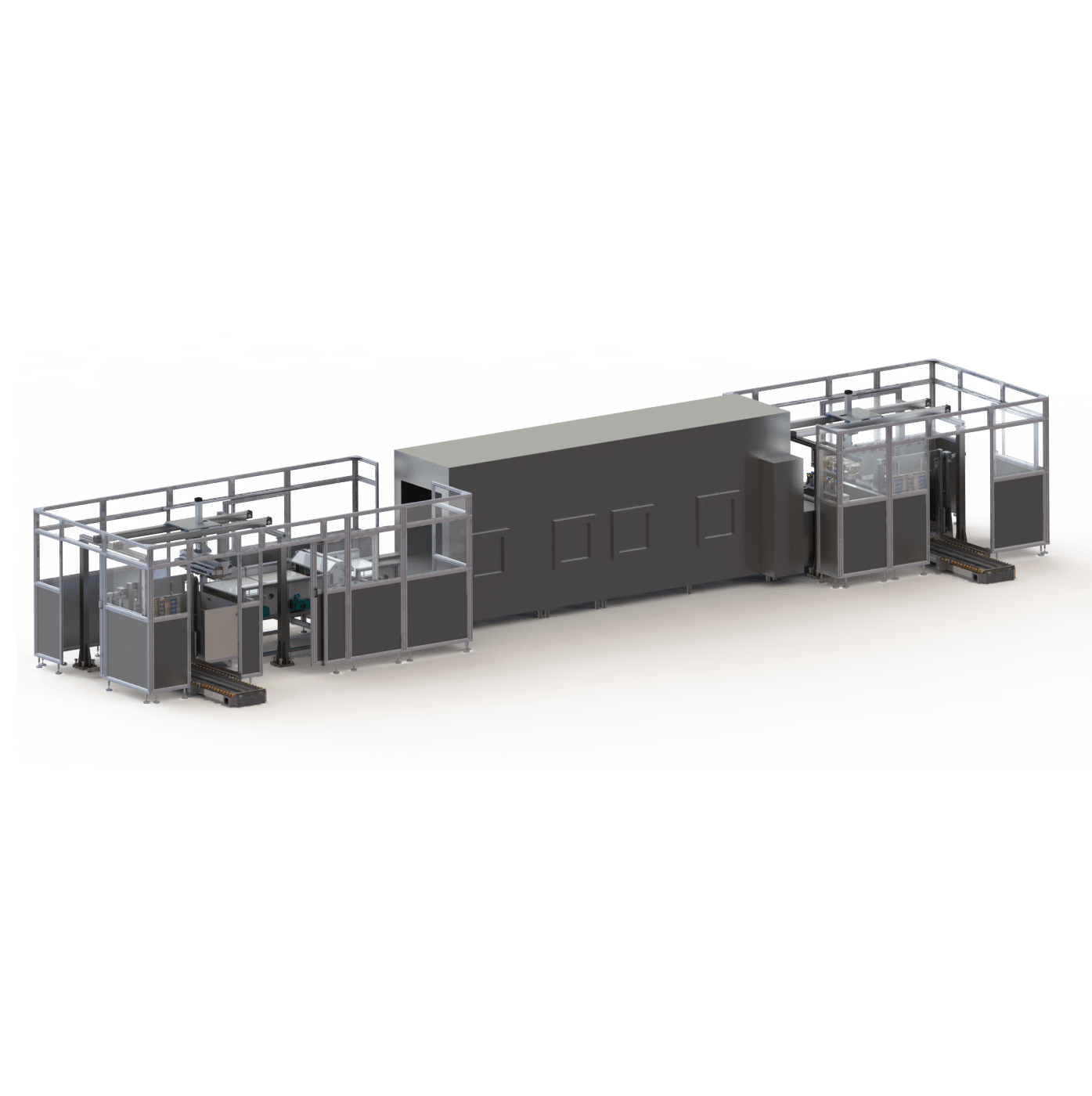

Visron Automated Cage Handling System 480

Quote

The VACH 480 by Visron Automation is a premium automated cage handling system designed to enhance vivarium operations. Engineered for compatibility with modern tunnel washers, it maintains precise cage positioning during the washing process, ensuring efficient and reliable performance. The system features a row-based pass-through mechanism and an active flip function, processing up to 650 cages per hour with minimal supervision. Its modular design accommodates various cage types, offering flexibility to meet diverse laboratory requirements. By integrating the VACH 480, facilities can significantly reduce labor costs and improve workflow efficiency.

Description

VACH 480 Product Highlights:

• High-Speed Automation: Processes up to 650 cages per hour, boosting throughput and productivity.

• Seamless Washer Integration: Designed to work flawlessly with modern tunnel washers for a streamlined workflow.

• Precision Handling: Ensures exact cage positioning for optimal cleaning and consistent results.

• Labor Cost Savings: Reduces manual handling requirements, lowering operational expenses.

• Flexible Compatibility: Accommodates various cage types and sizes with its modular design.

• Enhanced Efficiency: Row-based pass-through and active flipping functions improve operational flow.

• Durable and Reliable: Engineered with robust materials to withstand demanding vivarium environments.

• Compact Design: Optimized footprint to save space while maintaining high performance.

• Safety First: Equipped with advanced sensors and features for secure and worry-free operation.

• Proven Performance: Trusted system with demonstrated reliability in vivarium facilities worldwide.

• Processing Speed: Handles up to 650 cages per hour for high-throughput efficiency.

• Compatibility: Designed to integrate seamlessly with modern tunnel washers.

• Cage Positioning: Ensures precise alignment for optimal washing performance.

• Row-Based Mechanism: Includes pass-through functionality for smooth workflow integration.

• Active Flip Function: Automated cage flipping for thorough cleaning and consistent results.

• Modular Design: Adapts to various cage types and sizes to meet diverse facility needs.

• Automation: Minimizes manual handling, reducing labor requirements and costs.

• Construction: Built with durable, high-quality materials for long-lasting performance.

• Safety Features: Includes advanced sensors and controls to ensure operator safety.

• Dimensions: Compact footprint to maximize available space in vivarium environments.