Animal Vivarium Equipment and Supplies for Modern Research Facilities

Animal vivarium equipment encompasses the comprehensive infrastructure required to maintain healthy, compliant research animal colonies while supporting scientific objectives and ensuring regulatory compliance. Modern vivarium systems integrate advanced technologies for housing, husbandry, environmental control, and biosecurity that optimize animal welfare, enhance research reproducibility, and improve operational efficiency. From individually ventilated caging systems and automated watering to specialized anesthesia equipment and bedding disposal solutions, proper vivarium equipment creates controlled environments that protect both animals and research personnel while meeting stringent AAALAC, OLAW, and USDA standards.

ARES Scientific offers complete vivarium solutions encompassing rodent caging systems, automated watering systems, cage change stations, anesthesia equipment, bedding management systems, and specialized housing for diverse species from mice to primates. Our equipment partnerships with leading manufacturers including Animal Care Systems, Allentown, Tecniplast, and others ensure access to the latest innovations in animal research support technology. Whether establishing a new facility, upgrading aging infrastructure, or expanding capacity to support growing research programs, we provide expert guidance ensuring optimal equipment selection that balances animal welfare, operational efficiency, regulatory compliance, and budget constraints.

Common Applications and Research Areas

Animal vivarium equipment supports diverse research disciplines and institutional settings:

- Biomedical Research Institutions: Academic medical centers and research universities conducting disease modeling, drug development, genetics research, and translational studies requiring housing for thousands of mice, rats, and other species with rigorous environmental control and biosecurity

- Pharmaceutical and Biotechnology Companies: Preclinical drug development facilities performing efficacy testing, safety assessments, pharmacokinetics studies, and biologics development requiring GLP-compliant housing and validated equipment supporting regulatory submissions

- Contract Research Organizations (CROs): Multi-client testing facilities requiring flexible housing configurations, excellent biosecurity preventing cross-contamination, and scalable infrastructure accommodating variable study census

- Government Research Facilities: NIH, CDC, USDA, and military research installations supporting basic science, infectious disease research, vaccine development, and biodefense programs requiring specialized containment and security

- Behavioral and Neuroscience Programs: Psychology and neuroscience departments conducting learning, memory, addiction, and psychiatric disorder research requiring enriched housing environments and specialized behavioral testing integration

- Cardiovascular and Metabolic Research: Programs studying diabetes, obesity, heart disease, and metabolic syndrome requiring precise environmental control and specialized equipment for physiological monitoring

- Cancer Research Programs: Oncology facilities maintaining tumor models, immunodeficient colonies, and xenograft programs requiring barrier housing, specialized containment, and integration with imaging equipment

- Gnotobiotic and Microbiome Research: Programs studying host-microbe interactions requiring germ-free isolators and defined flora colonies with absolute biosecurity

Essential Categories of Vivarium Equipment and Supplies

Comprehensive vivarium operations require integrated equipment systems addressing all aspects of animal husbandry, facility operations, and research support.

Primary and Secondary Enclosure Systems form the foundation of vivarium infrastructure. Rodent caging systems include static microisolator cages for standard housing and individually ventilated caging (IVC) systems providing HEPA-filtered air supply to each cage, dramatically reducing allergen exposure, improving biosecurity, and allowing higher cage densities. Modern IVC racks incorporate automated monitoring, integrated watering, and energy-efficient designs reducing operating costs by 30-50% compared to conventional room ventilation. Species-specific housing options include rabbit caging, ferret housing, large animal enclosures for dogs and swine, and specialized systems for non-traditional species including marmoset caging and avian housing. Our guide on building IVC rack systems provides detailed selection criteria for these critical investments.

Watering Systems and Hydration Management ensure constant access to clean drinking water while minimizing contamination risks and labor requirements. Automatic watering systems deliver treated, monitored water through rack-mounted manifolds with individual cage valves, eliminating manual bottle filling and reducing water contamination. Automated bottle filling stations streamline operations for facilities using water bottles, while hydration gel systems provide supplemental hydration for shipping and post-procedural care. Water treatment including acidification, chlorination, or reverse osmosis purification prevents microbial contamination and supports defined microbiota protocols. Facilities transitioning to automation should review our article on vivarium automation benefits addressing efficiency gains and welfare improvements.

Cage Processing and Sanitation Equipment maintains biosecurity through validated cleaning and disinfection protocols. Cage change stations provide HEPA-filtered work surfaces protecting both animals and personnel during bedding changes and transfers. Options range from portable benchtop units to full-size Class II biosafety cabinet animal transfer stations for immunocompromised colonies requiring maximum containment. Automated cage washing infrastructure includes cage and bottle washers, tunnel washing systems for high-throughput facilities, and sterilizers for barrier facilities. Specialized wash racks and baskets accommodate different cage types ensuring thorough cleaning of complex geometries.

Bedding Management Systems automate labor-intensive bedding handling processes. Automated bedding dispensers including rainfall-style systems deliver precise bedding quantities directly into clean cages, reducing dust exposure and contamination risks. Bedding disposal stations with integrated vacuum systems safely contain used bedding and waste during cage changes, dramatically reducing allergen exposure—a critical consideration since laboratory animal allergy (LAA) affects up to 44% of animal care staff. Our comprehensive article on mitigating laboratory animal allergens details exposure reduction strategies. Proper bedding management is essential for both animal welfare and occupational health.

Material Handling and Transport Equipment enables efficient colony management and facility logistics. Bulk transport carts move multiple cage racks simultaneously, specialized animal transport carts maintain environmental control during inter-facility transfers, and bottle baskets streamline water bottle distribution. Ergonomic design considerations reduce staff injury from repetitive lifting and awkward postures common in vivarium operations.

Procedure Support Equipment facilitates research procedures while ensuring animal welfare and data quality. Anesthesia systems including precision vaporizers, scavenging systems, and induction chambers deliver controlled anesthesia for surgery, imaging, and procedures. Necropsy tables and containment hoods provide appropriate facilities for post-mortem examinations and tissue collection. Specialized procedure lighting ensures adequate illumination for delicate procedures. Proper anesthetic gas scavenging is essential for personnel safety—our article on reducing anesthetic gas exposure provides detailed guidance on containment strategies.

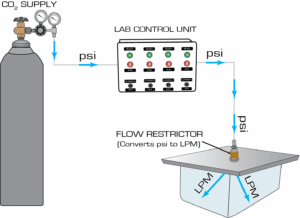

Euthanasia Systems enable humane endpoints meeting AVMA guidelines and IACUC requirements. Modern CO2 euthanasia systems incorporate automated gas flow controllers ensuring gradual chamber filling rates that minimize distress, integrated scavenging preventing personnel exposure, and data logging documenting protocol compliance. Our comprehensive guide on ethical rodent euthanasia addresses regulatory requirements, technique selection, and equipment specifications supporting humane endpoints.

Specialized Containment Systems support immunocompromised colonies and gnotobiotic research. Germ-free isolators maintain absolute sterility for axenic colonies and defined microbiota research, while flexible film isolators provide economical containment for immunodeficient models. Integration with sterile supply introduction systems and specialized waste removal maintains biosecurity throughout the breeding and experimental cycles.

How to Select Vivarium Equipment for Your Facility

Optimal vivarium equipment selection requires comprehensive evaluation of research needs, animal welfare standards, regulatory requirements, and operational constraints:

- Research Program Requirements Assessment: Define current and projected animal census by species, strain, and biosecurity level. Consider research protocols requiring specialized housing (SPF, germ-free, infectious disease containment). Account for breeding programs, aging studies, and other space-intensive protocols. Project 5-10 year growth accounting for expanding research programs and new investigator recruitment

- Regulatory and Accreditation Compliance: Ensure equipment meets AAALAC standards, OLAW Public Health Service Policy requirements, USDA Animal Welfare Act regulations (for covered species), and Guide for Care and Use of Laboratory Animals specifications. Consider institutional IACUC requirements potentially exceeding regulatory minimums. Facilities seeking AAALAC accreditation should specify equipment supporting performance standards

- Biosecurity and Containment Level: Match equipment to required biosecurity—conventional housing, barrier facilities requiring autoclaved supplies and validated sanitation, or containment housing for infectious disease research. ABSL-2 and ABSL-3 facilities require specialized equipment including containment primary enclosures, dedicated procedure areas, and validated decontamination systems

- Space Utilization and Density Optimization: IVC systems enable 2-3× higher animal densities compared to static caging through reduced ventilation requirements, allowing more productive use of expensive animal housing space. Calculate cost per cage position including rack system, facility infrastructure (HVAC, utilities), and operational expenses. Dense housing may reduce construction costs $200-$500+ per cage position

- Environmental Control Precision: Specify temperature and humidity control requirements—standard research (68-79°F, 30-70% RH) versus tight tolerances for metabolic studies or thermoneutrality experiments. IVC systems maintain microenvironments independent of room conditions, improving reproducibility and reducing facility HVAC costs. Consider circadian lighting systems supporting chronobiology research

- Ergonomics and Occupational Health: Equipment selection significantly impacts staff safety and retention. Prioritize systems reducing lifting (powered cage handling), controlling allergen exposure (IVC, automated bedding, cage change containment), and minimizing repetitive motions. Ergonomic improvements reduce injury rates, workers' compensation costs, and staff turnover in this physically demanding work environment

- Operational Efficiency and Labor Costs: Automated systems including IVC with integrated watering, robotic bedding dispensers, and automated cage washing reduce labor requirements by 30-50% compared to conventional operations. Calculate break-even points—capital investment in automation versus ongoing labor costs. For large facilities (5,000+ cages), automation typically pays back within 3-5 years. Review our article on vivarium automation for detailed ROI analysis

- Energy Efficiency and Sustainability: Modern IVC systems reduce facility HVAC energy consumption by 50-70% versus conventional room ventilation, lowering operating costs and supporting institutional sustainability goals. Consider LEED certification requirements—equipment energy efficiency contributes to green building goals. Our guide on LEED certification for vivariums addresses equipment specifications supporting sustainable design

- Vendor Support and Service Infrastructure: Evaluate manufacturer service networks, spare parts availability, and equipment lifecycle support. Complex automated systems require ongoing maintenance—verify local service availability or factor in travel costs for remote support. Consider equipment standardization reducing spare parts inventory and training requirements

- Integration with Facility Infrastructure: Coordinate equipment specifications with architectural and engineering teams early in planning. IVC systems require adequate electrical capacity (often 2-4 kW per rack), water supply for automated systems, waste disposal infrastructure, and appropriate structural loading. Retrofitting existing facilities may have constraints limiting equipment options

- Future Flexibility and Scalability: Specify modular equipment allowing incremental expansion. IVC racks should accommodate additional positions; automated systems should support increased throughput. Avoid overly specialized configurations limiting future research directions. Plan for technology upgrades—modern systems should remain supportable for 15-20 years

Our vivarium planning specialists conduct comprehensive facility assessments including census projections, workflow analysis, ergonomic evaluations, and budget development. We coordinate with architects, engineers, and regulatory consultants ensuring integrated facility design optimized for animal welfare, research quality, operational efficiency, and regulatory compliance.

Key Features to Compare Across Vivarium Equipment Systems

When evaluating equipment from different manufacturers, focus on these critical performance and operational characteristics:

- IVC System Airflow Performance: Compare cage-level ventilation rates (30-100+ air changes per hour), HEPA filtration efficiency (99.97%+ at 0.3 microns), and pressure differential maintenance (positive or negative pressure depending on application). Verify even airflow distribution across all cage positions. Systems with constant airflow regardless of cage occupancy maintain more stable environments

- Energy Efficiency and Operating Costs: Modern IVC racks with ECM motors and optimized airflow consume 40-60% less energy than first-generation systems. Calculate 10-year total cost of ownership including purchase price, energy ($200-$500+ per rack annually), maintenance, and replacement parts. Energy-efficient designs pay for incremental cost within 2-4 years through utility savings

- Noise Levels and Animal Welfare: Excessive noise (>70 dBA) causes chronic stress affecting research outcomes. Premium IVC systems operate at 50-65 dBA through sound-dampened blowers, vibration isolation, and acoustic enclosures. Quieter operation also improves work environments for staff spending extended periods in animal rooms

- Durability and Maintenance Requirements: Stainless steel and high-grade polycarbonate construction withstands repeated autoclaving and harsh chemical sanitizers. Compare warranty terms (5-10+ years on structural components) and projected blower lifespan (20,000-40,000+ hours). Modular designs enable field replacement of motors, valves, and other wear components without rack removal

- Watering System Reliability: Automatic watering requires consistent water delivery without leaks or blockages. Stainless steel manifolds and silicone valve seats resist corrosion and biofilm formation better than brass or rubber components. Verify ease of valve cleaning or replacement. Systems with individual cage shut-off valves prevent colony loss from single-point failures

- Cage Handling Ergonomics: Compare cage removal force, lid attachment mechanisms, and rack accessibility. Quick-release systems allow single-handed cage removal. Powered rack lifts eliminate bending and heavy lifting. Evaluate whether cage and food hopper designs minimize spills during changes—cleaner changes reduce cleaning time and cross-contamination risk

- Monitoring and Data Management: Advanced systems include rack-level sensors monitoring temperature, humidity, pressure differentials, and airflow rates with automatic alerts for out-of-range conditions. Integration with building management systems (BMS) and animal facility information management systems (AFIMS) enables centralized monitoring and automated data logging supporting SOP compliance and troubleshooting

- Adaptability and Research Support: Modular cage sizes and configurations accommodate changing research needs. Some systems support integration with automated behavioral monitoring, radiotelemetry receivers, or specialized lighting systems. Consider whether equipment will support anticipated research technologies over its 15-20 year service life

- Cleaning and Sanitation Compatibility: All components contacting animals should withstand validated cleaning methods—high-temperature washing (180°F+), chemical disinfection, or autoclaving. Seamless construction without crevices prevents biofilm accumulation. Removable components simplify thorough cleaning between studies or following disease outbreaks

- Species-Specific Design Considerations: Rabbit systems should accommodate larger animals (4-6 kg) with appropriate floor space and headroom. Primate housing requires enrichment provisions, perching opportunities, and complex social housing configurations. Aquatic systems require integrated life support with filtration, temperature control, and water quality monitoring. Verify equipment meets species-specific requirements in the Guide

Premium vivarium equipment incorporates predictive maintenance features using sensor data to forecast component failures before they occur, significantly reducing emergency repairs and animal losses from equipment malfunctions in mission-critical research facilities.

Maintenance and Operational Best Practices

Systematic maintenance ensures equipment reliability, animal welfare, regulatory compliance, and maximizes return on investment:

- Daily Operational Monitoring: Verify IVC rack blowers operating properly with normal airflow indicators. Check water delivery systems for leaks or blockages. Inspect cage change stations for proper airflow and HEPA filter indicators. Document any equipment malfunctions immediately and implement contingency plans (temporary housing, manual watering) protecting animal welfare during repairs

- Weekly Equipment Checks: Test emergency backup systems including battery backup for critical IVC racks. Inspect water treatment systems verifying proper operation and consumable levels (chlorine, acid, filters). Clean pre-filters in IVC racks extending HEPA filter life. Review automated monitoring data identifying trends indicating developing problems

- Monthly Preventive Maintenance: Conduct IVC airflow velocity measurements at representative cage positions verifying performance within specifications (typically ±20% of rated values). Clean blower intake filters and inspect motors for unusual vibration or temperature. Test watering system valves for proper flow—blocked valves risk dehydration. Calibrate monitoring sensors against reference instruments

- Quarterly Comprehensive Inspections: Replace IVC pre-filters per manufacturer schedules (typically every 3-6 months depending on room conditions). Inspect electrical connections, relays, and control systems. Perform complete water system sanitation including manifold flushing and valve descaling. Review equipment performance data and maintenance costs identifying high-maintenance items requiring attention

- Annual Certification and Validation: Conduct complete equipment performance verification including IVC airflow certification at all cage positions, HEPA filter integrity testing via DOP or photometric methods, water quality testing (microbiology, pH, hardness), thermocouple calibration for autoclaves and washers, and pressure testing for anesthesia systems. Maintain certification records supporting AAALAC accreditation and regulatory inspections

- HEPA Filter Management: Monitor pressure differentials across HEPA filters indicating loading. Replace filters when differential exceeds manufacturer specifications (typically 1.5-2× initial resistance) or every 2-5 years, whichever comes first. Document all filter changes including dates, types, and disposal methods. Never operate systems with compromised HEPA filtration—this directly impacts animal health and research integrity

- Water Quality Monitoring: Test water microbiology monthly (or more frequently for immunocompromised colonies) using standard plate counts. Monitor pH, hardness, and chlorine residuals weekly for treated water systems. Conduct annual comprehensive water analysis including heavy metals and endotoxins for critical applications. Poor water quality is a common cause of unexplained animal health problems

- Sanitation Protocol Validation: Periodically verify cage washing and sterilization processes achieve validated kill levels using biological indicators (Bacillus stearothermophilus spores for autoclaves, ATP swabs for wash efficacy). Document time-temperature relationships for thermal disinfection. Revalidate processes after equipment repairs, cycle modifications, or following disease outbreaks

- Staff Training and Competency: Provide comprehensive initial training on equipment operation, troubleshooting, and emergency procedures. Conduct annual refresher training and competency assessments. Document all training activities. Well-trained staff identify equipment problems early, operate systems more efficiently, and make fewer costly errors affecting animal welfare and research

- Spare Parts Inventory Management: Maintain critical spare parts for equipment with long lead times or supporting essential operations—IVC blower motors, watering valves, cage change station filters, anesthesia vaporizer diaphragms. Calculate appropriate inventory levels balancing storage costs against downtime risks. Establish relationships with local distributors for expedited parts delivery

- Long-Term Capital Planning: Track equipment age, maintenance costs, and performance degradation. Budget for major replacements on 15-20 year cycles for IVC systems, 10-15 years for washing equipment, 5-10 years for anesthesia machines. Proactive replacement before critical failures prevents emergency procurements, animal welfare incidents, and research disruptions

Implementing computerized maintenance management systems (CMMS) streamlines work order tracking, preventive maintenance scheduling, spare parts inventory, and equipment history documentation—essential for large vivarium operations managing hundreds of equipment assets.

Frequently Asked Questions

What is the difference between conventional and IVC housing, and when should I use each?

Conventional housing uses standard cages with filter tops or microisolator lids placed in temperature and humidity-controlled rooms with 10-15 air changes per hour. All cages in the room share the same environment. Individually Ventilated Caging (IVC) systems provide HEPA-filtered air supply directly to each cage at 30-100+ air changes per hour, creating independent microenvironments. IVC advantages include: dramatically reduced allergen exposure for personnel (50-90% reduction), improved biosecurity preventing cross-contamination between cages, ability to house 2-3× more cages per room (reduced ventilation requirements), more stable and reproducible cage environments (temperature, humidity, ammonia), and potential for 50-70% reduction in facility HVAC energy costs. Conventional housing advantages include: lower capital cost ($500-1,000 per cage position versus $1,500-3,000 for IVC), simpler maintenance requirements, easier cage access for frequent observations, and no risk of ventilation system failure affecting animals. Use IVC for: facilities housing >1,000 cages where density and efficiency benefits justify investment, immunocompromised colonies requiring superior biosecurity, personnel with laboratory animal allergies, new construction where reduced HVAC infrastructure offsets rack costs, and longitudinal studies where environmental stability improves reproducibility. Use conventional housing for: small facilities (<500 cages) where IVC economics don't justify investment, behavioral studies requiring frequent undisturbed observation, short-term studies where environmental variations are acceptable, and quarantine areas where disposable housing prevents equipment contamination. Many facilities use hybrid approaches—IVC for breeding and long-term studies, conventional for short-term experiments and special procedures. Our article on IVC rack configuration provides detailed selection guidance.

How do I calculate staffing requirements for vivarium operations?

Staffing requirements depend on animal census, housing type, protocols, and automation level. General guidelines: Conventional housing requires 1 FTE animal care technician per 500-800 rodent cages or 40-60 rabbit cages, assuming standard husbandry (3× weekly cage changes, daily health checks, routine procedures). IVC systems with automated watering reduce labor by 25-35%—1 FTE per 700-1,200 cages. Automated bedding dispensers and cage washing systems provide additional 15-25% efficiency gains. Specialized protocols increase staffing needs: breeding colonies require 20-30% more time for pup processing and weaning, quarantine and health surveillance programs add 0.5-1 FTE per 1,000 animals, technical procedures (injections, blood collection, dosing) require dedicated procedure staff separate from husbandry, gnotobiotic isolator operations are extremely labor intensive (1 FTE per 40-60 isolator cages), and regulatory compliance activities (record keeping, training, SOP maintenance) require 0.5-1 FTE per 5-10 technician staff. Management and supervision requires approximately 1 supervisor per 5-8 technicians, 1 veterinarian per 5,000-10,000 animals (species dependent), 1 veterinary technician per 2,000-5,000 animals, and administrative support (1 FTE per 10-15 total vivarium staff). Cage washing and sterilization typically requires 1 FTE per 500-800 cages washed daily (conventional), or 1 FTE per 1,000-1,500 cages (automated tunnel washers). Calculate specific needs by tracking time-motion studies—document actual time for each task (cage changes, water bottle filling, animal observation, procedure support) and multiply by frequency and census. Include allowances for training, breaks, vacation coverage, and unforeseen tasks. Understaffing compromises animal welfare, research quality, and staff safety—adequate staffing is essential for regulatory compliance and AAALAC accreditation. Our article on vivarium automation quantifies labor reduction from different automation strategies.

What are the essential considerations for vivarium facility design and planning?

Successful vivarium planning requires early integration of research programs, architectural design, engineering systems, equipment specifications, and regulatory requirements. Critical design considerations include: Animal holding capacity sizing based on 5-10 year research projections including breeding space (typically 40-60% of total capacity), experimental space, quarantine (10-15% of capacity), and contingency space (20-30% buffer for growth). Space programming should include procedure rooms (1 per 2,000-3,000 rodent cages), surgery suites for survival procedures, cage washing and sterilization areas (size based on daily throughput), clean and dirty storage corridors (supporting one-way flow), staff areas (lockers, break rooms, offices), and specialized spaces (imaging, behavioral testing, necropsy). Mechanical systems require careful attention: HVAC systems must provide 10-15 room air changes/hour (conventional) or reduced rates with IVC (6-10 ACH), maintain temperature 68-79°F ±2°F and humidity 30-70% ±10%, ensure negative pressure relative to corridors (-0.02 to -0.05" WC), and provide redundant cooling and backup power for critical spaces. Plumbing infrastructure includes water treatment systems (RO, acidification, chlorination based on protocols), adequate drainage for cage washing areas, emergency eyewash and safety showers, and backflow prevention. Electrical systems require adequate capacity for IVC racks (2-4 kW per rack), automated equipment, and lighting with emergency backup for critical systems. Architectural considerations include smooth, seamless finishes facilitating cleaning, separate clean and dirty corridors preventing cross-contamination, appropriate door sizes for equipment and rack movement (minimum 42" wide, 84" high), and appropriate finishes resisting chemicals and repeated cleaning. Biosecurity design includes hands-free operation where possible (foot-pedal doors, automatic faucets), HEPA-filtered air supply to critical areas, pass-through autoclaves and cage washers between dirty and clean zones, appropriate gowning areas with PPE storage, and controlled access systems. Sustainability features supporting LEED certification include energy-efficient IVC reducing HVAC loads, heat recovery systems, LED lighting with occupancy sensors, and water-efficient equipment. Engage specialized laboratory animal facility architects and engineers early—vivarium design requires expertise beyond typical laboratory buildings. Our comprehensive guide on LEED certification for vivariums addresses sustainable design strategies and equipment specifications.

How do I manage laboratory animal allergen exposure and protect staff health?

Laboratory animal allergy (LAA) affects 20-44% of individuals working with laboratory animals, causing rhinitis, conjunctivitis, asthma, and in severe cases anaphylaxis. Comprehensive allergen management requires hierarchy of controls: Engineering controls (most effective): IVC systems reduce ambient allergen concentrations by 50-90% compared to conventional housing, automated bedding dispensers eliminate high-exposure dust clouds during bedding handling, negative pressure cage change stations with HEPA filtration contain allergens during changes, ventilated necropsy stations prevent aerosol exposure during dissections, and properly functioning facility ventilation with 10-15+ air changes per hour dilutes airborne allergens. Administrative controls include minimizing time in high-allergen areas, scheduling high-allergen tasks (cage changes, bedding handling) when fewer personnel present, job rotation limiting cumulative exposure, and pre-placement medical evaluations identifying susceptible individuals. Personal protective equipment (PPE) including N95 respirators (not surgical masks which don't filter allergens), powered air-purifying respirators (PAPRs) for high-exposure tasks, impermeable gowns and gloves preventing skin contact, and eye protection preventing conjunctival exposure. Medical surveillance programs should include baseline pulmonary function testing, annual symptom questionnaires, periodic spirometry for symptomatic individuals, and access to occupational health services for evaluation and treatment. Early symptom recognition and intervention prevents progression to chronic asthma—employees developing symptoms should immediately report to occupational health. Facilities should provide allergen immunotherapy (allergy shots) access for affected employees when clinically appropriate. Environmental monitoring through allergen sampling (ELISA assays for rodent allergens) verifies control effectiveness and identifies problem areas. Staff education on LAA symptoms, prevention strategies, and importance of PPE compliance is essential—many workers attribute symptoms to colds or irritation rather than allergy. Implement medical removal programs for employees developing severe symptoms unresponsive to treatment—continued exposure risks life-threatening reactions. Our detailed article on laboratory animal allergen management provides comprehensive guidance on exposure reduction strategies and equipment selection minimizing allergen release.

What are the requirements for ethical euthanasia in research settings?

Humane euthanasia must follow AVMA Guidelines for the Euthanasia of Animals and IACUC-approved protocols. Acceptable methods for rodents include: Carbon dioxide (CO2) euthanasia using gradual fill rates (10-30% chamber volume per minute) to minimize distress—rapid CO2 introduction causes pain. Proper technique requires pre-filling chambers to 10-30% CO2 before introducing animals, then maintaining flow until at least 1 minute after respiratory arrest. Secondary methods (cervical dislocation, decapitation, thoracotomy) must confirm death. Inhalant anesthetic overdose (isoflurane, sevoflurane) is acceptable but more expensive than CO2. Injectable barbiturate overdose (pentobarbital) via IP or IV routes is acceptable but requires DEA registration and controlled substance protocols. Unacceptable methods include: hypothermia, drowning, rapid CO2 introduction causing air hunger, chloroform or ether, nitrogen/argon gas alone without prior anesthesia (unless specifically justified), and physical methods without anesthesia except where scientifically justified. Equipment requirements: Euthanasia chambers should be transparent allowing observation, appropriate size for species (not overcrowded), easy to clean and disinfect, and equipped with CO2 regulators and flowmeters enabling controlled delivery rates. Modern systems include automated controllers preventing rapid CO2 introduction, integrated timers ensuring adequate exposure duration, and scavenging systems protecting personnel from CO2 exposure. Additional considerations include: personnel must be properly trained in euthanasia techniques with documented competency, IACUC protocols must specify method, justification, and confirmation procedures, neonatal rodents (<10 days) are resistant to CO2—alternative methods may be required, and death confirmation is mandatory before disposal—lack of respiration for 1+ minutes plus lack of heartbeat. Euthanasia must be performed humanely even when animals are severely compromised or moribund. Psychological stress on personnel performing euthanasia should be acknowledged—provide counseling resources and job rotation. Our comprehensive guide on ethical rodent euthanasia provides detailed protocols and equipment specifications ensuring AVMA and IACUC compliance.

How do I maintain biosecurity and prevent disease introduction in my vivarium?

Comprehensive biosecurity requires multi-layered approaches addressing all potential disease introduction routes: Procurement biosecurity: source animals only from reputable vendors with documented health surveillance programs, require health reports (FELASA, SOPF, or equivalent) before arrival, implement mandatory quarantine for new arrivals (minimum 7-14 days, ideally 30+ days for primates), perform baseline health assessment including serology or PCR for common pathogens, and house quarantine animals in separate rooms with dedicated equipment and staff. Facility access control: limit vivarium access to trained, authorized personnel, implement appropriate gowning protocols (dedicated shoes/boots, scrubs, lab coats, gloves, hair covers), consider shower-in/shower-out for high-security facilities, restrict personnel movement between animal areas of different health status, and prohibit contact with outside animals (24-72 hour restriction after pet contact). Equipment and supply sanitation: sterilize or disinfect all materials entering animal areas (autoclaving preferred for critical items), validate cage washing and sterilization processes with biological indicators, use filtered air supply for cage change stations and IVC systems, and implement proper waste disposal preventing fomite transmission. Personnel training: comprehensive biosecurity training for all staff including disease recognition, aseptic techniques, proper gowning procedures, and appropriate responses to breaches. Environmental controls: maintain appropriate pressure differentials (barriers negative to corridors), ensure HEPA filtration of supply air to critical areas, separate clean and dirty workflows preventing cross-contamination, and implement pest control programs. Health surveillance: conduct routine sentinel programs testing representative animals quarterly or semi-annually, investigate unexplained morbidity/mortality promptly with diagnostic workups, maintain disease-free certification through regular testing, and implement response plans for disease detection (depopulation, rederivation, containment). IVC systems provide superior biosecurity versus conventional housing by isolating individual cages from environmental contamination and cage-to-cage transmission. Immunocompromised colonies (nude, SCID, NSG) require additional measures including autoclaved water, irradiated feed, and HEPA-filtered air supply. For highest-security applications, flexible film isolators maintain absolute barriers. Consult veterinary staff on appropriate biosecurity level for your research programs—over-investment in biosecurity wastes resources, under-investment risks costly disease outbreaks destroying valuable colonies and compromising research. Our article on vivarium automation discusses biosecurity benefits of automated systems reducing contamination risks from manual procedures.

What factors should I consider when choosing between different rodent species for research?

Species selection requires balancing scientific validity, practical considerations, and resource availability: Mice (Mus musculus): Most commonly used research species due to extensive genetic resources (knockout/transgenic lines), short generation time (7-9 weeks to sexual maturity, 19-21 day gestation), small size enabling high-density housing and low feeding costs ($1-2 per animal per day), well-characterized biology and physiology, extensive reagent availability (antibodies, assays), and established disease models. Disadvantages include small blood volumes limiting serial sampling, technical challenges for some procedures (vascular access, surgery), and physiological differences from humans (metabolism, immune function). Rats (Rattus norvegicus): Advantages include larger size facilitating surgical procedures, blood sampling, and vascular access, longer lifespan supporting aging studies, more complex behavioral repertoire for neuroscience, and physiological similarities to humans in some systems (cardiovascular, toxicology). Disadvantages include higher housing and feeding costs ($3-5 per animal per day), less extensive genetic resources versus mice (though improving rapidly with CRISPR), larger space requirements reducing housing density, and longer generation time (10-12 weeks maturity, 21-23 day gestation). Other rodent species: Guinea pigs offer advantages for immunology, reproductive biology, and vitamin C metabolism studies but require larger cages and have limited genetic resources. Hamsters are useful for circadian rhythm research, infectious diseases, and hibernation studies. Gerbils serve specific applications in auditory research and stroke models. Non-rodent species selection depends on specialized requirements—regulatory testing may mandate specific species, translational research may require species phylogenetically closer to humans (primates, dogs, swine), or unique biological features may be essential (zebrafish for developmental biology, ferrets for respiratory diseases). Practical considerations include facility capacity and expertise (introducing new species requires specialized training, housing, and veterinary support), regulatory requirements (USDA-covered species require additional compliance burden), cost implications (purchase price, housing costs, per diem rates, and study duration), and availability of research resources (reagents, disease models, historical data). Institutional support including veterinary expertise, established husbandry protocols, and appropriate housing infrastructure significantly influences species selection—introducing species without adequate support risks animal welfare problems and research quality issues. Consult with comparative medicine veterinarians, literature review of species-appropriate models, and cost-benefit analysis before committing to species selection—changing species mid-program disrupts research and wastes resources.

Related Vivarium and Research Equipment

Comprehensive vivarium operations integrate with broader research infrastructure and support systems. Related equipment categories include:

Request a Quote for Vivarium Equipment and Planning Support

ARES Scientific's vivarium specialists provide comprehensive support from initial facility planning through equipment installation, staff training, and ongoing service. Our team has extensive experience supporting academic research institutions, pharmaceutical companies, contract research organizations, and government facilities with vivarium infrastructure ranging from small satellite facilities to large-scale centralized operations housing tens of thousands of animals.

We offer complete project management services including research program assessment and animal census projections, comprehensive equipment specification and vendor evaluation, facility design consultation and coordination with architects and engineers, regulatory compliance guidance supporting AAALAC accreditation, utility requirement assessment and infrastructure planning, equipment installation supervision and commissioning support, comprehensive staff training programs with competency certification, preventive maintenance program development and service support, and operational consulting optimizing workflows and staffing efficiency.

Whether establishing a new vivarium, renovating existing facilities, upgrading to modern IVC and automation systems, expanding capacity to support research growth, or transitioning to more sustainable operations, our consultative approach ensures optimal equipment selection balancing animal welfare, research quality, operational efficiency, regulatory compliance, and institutional budget constraints.

Connect with our vivarium planning specialists:

- Request a detailed quote and facility assessment

- Schedule a virtual consultation to discuss your vivarium needs and timeline

- Arrange equipment demonstrations at our facility or your site

- Receive comparative analysis of equipment options with TCO calculations

- Discuss sustainability goals and LEED certification support

Nationwide delivery, installation, and commissioning services available. Ask about our comprehensive service agreements including 24/7 emergency support for critical systems, annual preventive maintenance and equipment certification programs, staff training and continuing education services, and long-term capital planning support ensuring your vivarium maintains peak performance, regulatory compliance, and animal welfare excellence throughout the 15-20 year equipment lifecycle. Financing and leasing options available for qualified research institutions.