Purpose

Sterilization is a mandatory procedure in healthcare, pharmaceutical, and research sectors. Dry heat and steam sterilization are two prevalent methods with unique advantages, drawbacks, and applications. This article delivers crucial insights into the intricate realm of steam versus dry-heat sterilization, aiming to assist your decision-making process for your facility. It begins with an introductory exploration of these two sterilization techniques and highlights their differences and then delves into an evaluation of each method.

Dry-Heat Sterilization: The Basics

Dry-heat sterilization is a simple yet effective process where items are subjected to high temperatures within a heating cabinet or conveyor tunnel. The sterilization process involves heating the items to be sterilized by heating the air within the sterilizer using electrical heating elements. Efficiency can be increased by complimenting heating by circulating the air using internal circulation fans..

Depending on the items being sterilized, the temperature during dry-heat sterilization generally ranges from 130°C to 160°C, sufficient for sterilization of pathogens including spores, up to 250°C, the minimum requisite for depyrogenation. Higher temperatures and longer exposure times are required for depyrogenation compared to sterilization alone. Dry-heat sterilization is achieved by conduction; heat is absorbed by the outer surface of the item and gradually moves towards the center. Every surface of the item eventually reaches the temperature required for sterilization but at a much slower rate than steam sterilization. This method kills organisms mainly by oxidizing molecules, destroying essential cell constituents.

There are two types of dry-heat sterilizers: static-air and forced-air. The static-air sterilizer, also known as the gravity-type sterilizer, is slower in heating, requires more time to reach sterilizing temperature, and exhibits less uniform temperature control throughout the chamber than the forced-air sterilizer. The forced-air, or mechanical convection, sterilizer uses a motor-driven blower that circulates heated air throughout the chamber at high velocity, allowing a more rapid transfer of energy from the air to the instruments.

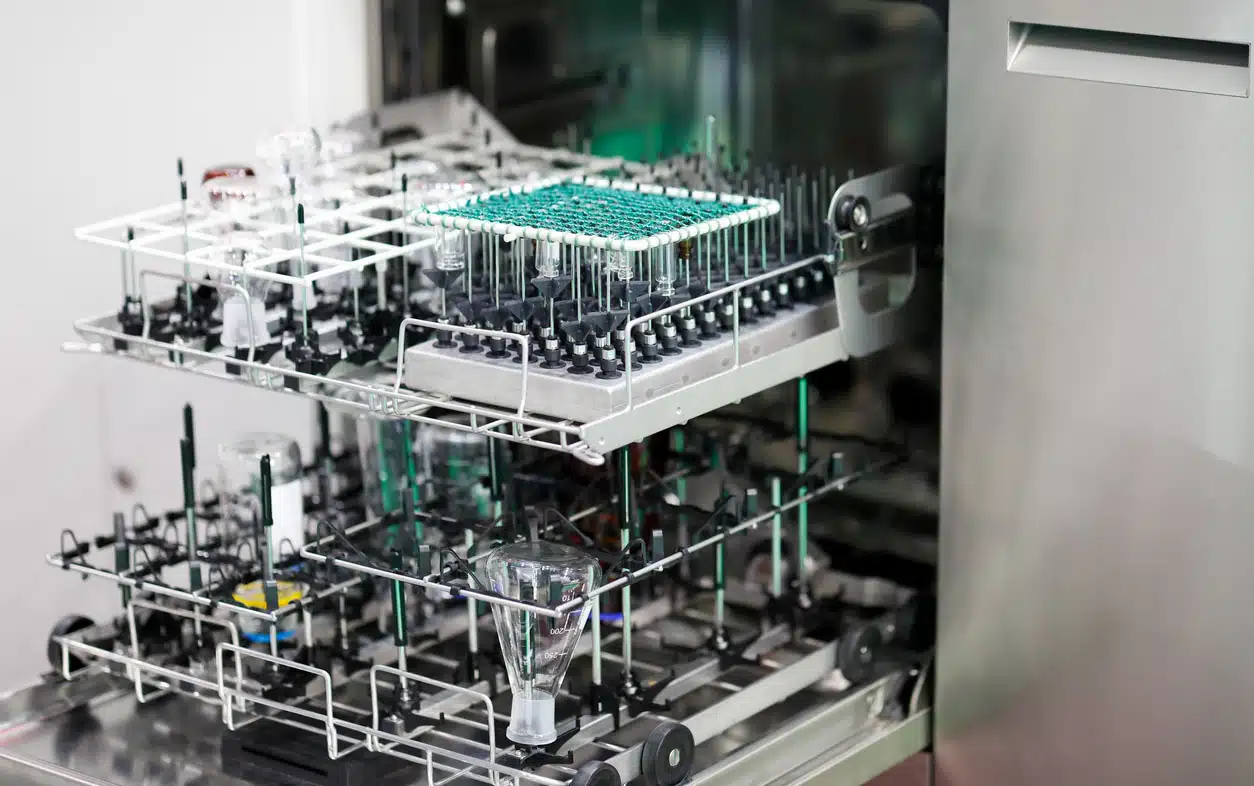

Dry-heat sterilization systems, including cabinet ovens and conveyor tunnels, regulate temperature, time, and blower speed during the process. In tunnel sterilizers, items transition from heating zones to cooling zones for sterilization and depyrogenation. While tunnel sterilizers offer certain advantages, they are complicated to validate due to the challenge of maintaining uniform heating across the conveyor system.

Advantages and Disadvantages of Dry-Heat Sterilization

Dry-heat sterilization has several benefits. These include eliminating the need for steam, condensate return, water, pit, drain and structural reinforcement to hold the weight. Dry heat sterilizers use far less energy than steam sterilizers and reject far less heat than steam sterilizers. They may be designed in modules and assembled on site, eliminating the need for construction to get the sterilizer into the facility. Lastly, in most cases, the dry heat sterilizer will occupy less floor space.

Dry heat sterilization is extremely effective at sterilizing caging (with or without bedding and food), IVC racks, water bottles, water, enrichment and other items typically used in the vivarium. Cycles are validated using 10-6 spore strips and many studies exist confirming efficacy on a variety of pathogens. In recent years, many improvements in the technology have yielded much shorter cycle times and ability to sterilize previously difficult to sterilize materials. Of major not, dry heat sterilizers configured for BL2, BL3 and VHP applications have been introduced to the industry with great success.

There are some limitations of dry heat sterilization. Primarily, sterilizing bulk items in larger bags, of food or bedding for example, may prove very time consuming. When used for waste applications, dry heat sterilizers cannot sterilize materials saturated in flammable solvents, such as isopropyl alcohol.

Steam Sterilization: An Overview

Unlike dry-heat sterilization, steam sterilization uses saturated steam to deactivate microorganisms. The material is exposed to steam at a specific temperature and time, allowing the heat of condensation to release energy and eradicate microorganisms effectively.

Dry-Heat Vs. Steam Sterilization: The Comparison

Both dry-heat and steam sterilization are effective, but they differ significantly in their mechanics and efficiency. Dry heat penetrates the interiors of items through conduction, but this process is time-consuming. Steam sterilization, on the other hand, is faster and more efficient but may not be suitable for materials that are sensitive to moisture or high temperatures. Moreover, while dry heat sterilization is non-corrosive, non-toxic, and environmentally friendly, it is not suitable for all types of materials, particularly those that can’t withstand high temperatures. Additionally, steam sterilization cannot reach temperatures needed to routinely kill hardier microorganisms.

In conclusion, the choice between dry-heat and steam sterilization largely depends on the specific needs and constraints of the sterilization procedure, such as the nature of the material to be sterilized, the speed and efficiency required, and the available resources. It is essential to consider these factors when deciding between these two methods of sterilization.

The Affordability and Simplicity of Dry-Heat Sterilization: A Comparative Analysis

Affordability of Dry-Heat Sterilization

One of the most compelling advantages of dry-heat sterilization is the overall project cost. Dry heat sterilizers require no pit, no structural reinforcement to the building to hold the weight, no drain, no water and no steam capture hoods. Each project is evaluated looking at the space available, throughput required, loading trucks, installation path, workflow and ergonomics. From there, the dry heat sterilizer is designed to meet all of the requirements and utilize the space efficiently. Dry heat sterilizers are designed in modules, sized to be brought into the facility without the need for construction. Because of these advantages, dry heat sterilizers save hundreds of thousands to millions of dollars on the project cost.

Second, the operating costs associated with dry-heat sterilizers are also generally lower. They do not require water to generate steam, thereby eliminating the need for a constant water supply and the considerable costs associated with boiling water. Furthermore, maintenance costs are also lower as there are fewer mechanical parts that can fail compared to an autoclave.

Simplified Facility Requirements

As mentioned above, compared to steam sterilization, dry-heat sterilization has less stringent facility requirements, making it more convenient and adaptable. Dry-heat sterilizers also have a low maintenance cost and tend to radiate less heat to room.

Space: Dry-heat sterilizers come in various sizes, including compact models that can fit comfortably in small laboratories or clinics. Unlike autoclaves, they do not require additional space for water reservoirs or drainage systems.

Ventilation: Dry-heat sterilization does not produce steam, thereby eliminating the need for complex ventilation systems designed to handle steam output.

Power Supply: Both types of sterilizers require a suitable power supply, but dry-heat sterilizers only require electricity while steam sterilizers also need water, steam, condensate return and a drain.

Infrastructure: Dry-heat sterilizers do not require plumbing connections for water supply and drainage, simplifying the installation process and reducing the need for facility modifications.

Efficiency and Efficacy

While dry-heat sterilization does require slightly longer cycles than steam sterilization, it excels in sterilizing items that are impenetrable to moist heat or are prone to damage by moisture, such as powders, petroleum products, and sharp instruments. It offers thorough penetration and is non-corrosive for metal and sharp instruments, increasing the lifespan of sterilized equipment. It also more routinely deactivates hardier microorganisms that are more resistant to the temperatures generated by steam sterilization.

In conclusion, the choice between dry-heat and steam sterilization largely depends on the specific needs and constraints of a facility. However, for those seeking a more affordable option with simpler facility requirements, dry-heat sterilization emerges as a compelling choice. Its ability to effectively sterilize a broad range of materials and its relative ease of installation and operation make it an ideal option for many healthcare and laboratory settings.

The Investment Case for Steam Sterilization: A Comparative Analysis

Efficiency of Steam Sterilization

A standout advantage of steam sterilization is its unrivaled efficiency. Steam sterilization units, often referred to as autoclaves, typically complete the sterilization process in less time compared to dry-heat sterilizers. The combination of high pressure and steam in an autoclave enables quicker penetration of heat, leading to faster sterilization cycles. Additionally, steam sterilization is effective against a broad range of microorganisms.

Material Compatibility

Steam sterilization is often preferred for its compatibility with a wide variety of materials. Many materials, such as certain types of plastic and rubber, that may degrade or melt at the high temperatures used in dry-heat sterilization, can safely undergo steam sterilization. This flexibility makes steam sterilization a versatile solution for many healthcare facilities and laboratories.

Facility Requirements and Long-term Investment

Steam sterilization requires a higher initial investment, higher maintenance costs, and more complex facility requirements compared to dry-heat sterilization. However, the additional versatility and faster sterilization times of steam units can make them the better choice based on a facilities needs and budget.

Space: Autoclaves come in various sizes to suit different facility needs. They may require additional space for water reservoirs and drainage systems requiring an infrastructure investment. The benefit of the additional infrastructure investment for a steam unit are faster and more versatile sterilization.

Ventilation: Although steam sterilization produces steam that requires proper ventilation, this is typically manageable with standard facility HVAC systems.

Infrastructure: While autoclaves do require plumbing connections for water supply and drainage, these are standard in most healthcare facilities. Furthermore, the water used in the sterilization process often does not require special treatment before disposal.

Power Supply: Autoclaves do require a robust power supply for heating the water to generate steam. The energy requirements for a steam autoclave are typically higher than a dry heat unit, but the faster sterilization cycles often justify the cost for facilities that choose this method.

Conclusion

While dry-heat sterilization offers lower initial costs, lower maintenance costs and simpler facility requirements, the efficiency and versatility of steam sterilization can make it an attractive investment for many facilities. The ability to sterilize a wider range of materials and achieve sterilization more quickly can lead to increased productivity and assurance of sterility, crucial aspects in healthcare and laboratory environments.

ARES Scientific has positioned itself as an industry leader by offering flexible and comprehensive sterilization solutions that cater to the unique requirements of every facility. The company’s extensive portfolio incorporates both steam and dry-heat sterilization technologies, demonstrating their commitment to meeting the varied sterilization needs that facilities may have.

Their steam sterilization solutions offer a dependable, tried-and-true method that is recognized for its efficiency and effectiveness in eliminating microbial contamination. This solution is particularly suitable for heat-stable, moisture-tolerant items and has been widely adopted in various sectors, including healthcare, pharmaceuticals, and food processing.

On the other hand, ARES Scientific’s dry-heat sterilization solutions provide an invaluable alternative for sterilizing heat-stable, moisture-sensitive items or for instances where steam sterilization may not be appropriate. This approach provides consistent, high-temperature sterilization that is especially effective for instruments that need to remain dry, or materials that might be damaged by the moisture of steam sterilization.

What sets ARES Scientific apart is not just the breadth of its sterilization offerings, but also its commitment to quality, safety, and ongoing innovation. Its solutions are designed to deliver reliable performance, easy operation, and maximum efficiency, contributing to the overall success and productivity of any facility. By continuously evolving its products and services in response to emerging needs and advances in sterilization technology, ARES Scientific remains at the forefront of providing effective and tailored sterilization solutions for a diverse range of facilities.

Please contact us for assistance in selecting the right unit for your facility.