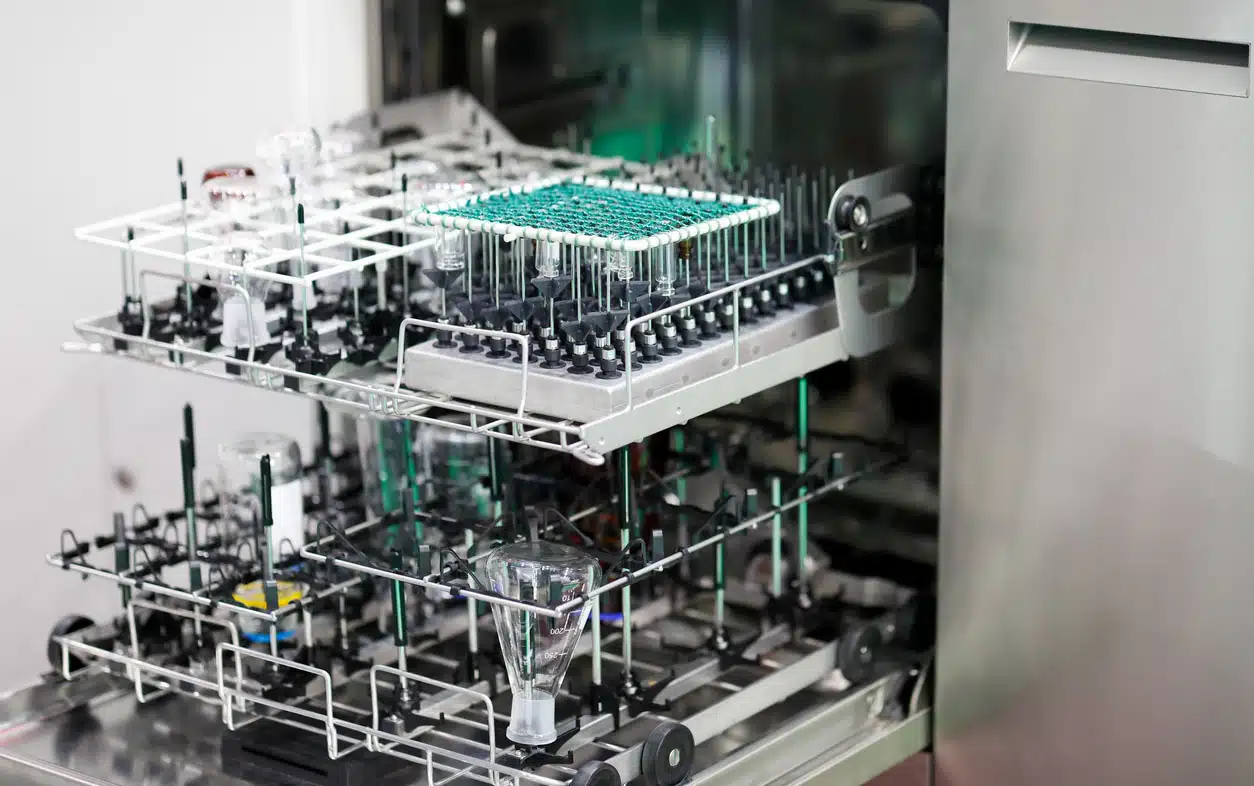

Pharmacy isolators are specialized equipment that provides a controlled and sterile environment for handling hazardous materials and conducting aseptic preparations in the pharmaceutical industry. They consist of bacteriologically sealed enclosures that create a controlled atmosphere during production. To ensure high safety and sterility levels, this equipment will be manufactured to stringent industry standards and guidelines, for example, ISO classes or USP 797. The main isolator chamber provides a sterile workspace equipped with shoulder-high gloves for handling products, storage, or packaging.

Depending on the specific application, pharmacy isolators can operate under positive or negative pressure. Positive pressure isolators are commonly used for aseptic applications, eliminating the need for additional cleanroom facilities and reducing operating costs. On the other hand, negative pressure isolators are employed when handling hazardous materials to ensure containment and operator safety.1

Now that we have provided an overview of pharmacy isolators, we will explore the factors that influence the performance of pharmacy isolators and discuss their benefits in the pharmaceutical industry.

The Performance of Pharmacy Isolators

Several key factors influence the performance of pharmacy isolators, which impact the effectiveness of isolators in ensuring product quality, operator safety, and preventing contamination. Some of those include air velocity, HEPA filter integrity, and humidity, and understanding and managing all relevant factors is crucial for maintaining the optimal performance and effectiveness of isolators in the pharmaceutical industry.

Now, let’s take a more in-depth look at the full range of factors that impact pharmacy isolators.

Air Velocity

The proper air velocity helps maintain airflow within the isolator, minimizing the risk of contamination. The velocity should be optimized to ensure the movement of particles away from the work zone and prevent them from accumulating.

Differential Pressure Test

Differential pressure, whether positive or negative, is crucial for preventing contaminants from escaping. Regular differential pressure testing must be conducted to ensure that the isolator maintains the required pressure differentials, which will provide effective containment.

HEPA Filter Integrity

High-efficiency particulate air (HEPA) filters are critical in removing airborne particles and microorganisms from the incoming air supply. Regular monitoring and testing of HEPA filters ensure their integrity and effectiveness in maintaining a sterile environment.

Microbial Contamination

Pharmacy isolators must be regularly checked for microbial contamination to maintain aseptic conditions. Microbial monitoring systems help identify and address any potential sources of contamination, protecting the product and operators.

Non-Viable Particulate

Monitoring non-viable particulate levels within the isolator is essential to ensure compliance with industry standards, such as ISO classes or USP 797 guidelines. Correct control of non-viable particulate helps minimize the risk of contamination during pharmaceutical processes.

Temperature and Relative Humidity

Proper temperature and relative humidity control are crucial for maintaining the required conditions within the isolator. Any changes from the specified ranges can affect the pharmaceutical compounds’ stability and compromise the product’s sterility.

Where Can I Purchase a Pharmacy Isolator?

The demand for pharmacy isolators is growing steadily due to the expanding use of sterilized procedures, automation, and advancements in isolator efficiency. Market reports have predicted significant growth in the pharmaceutical isolators market as pharmaceutical companies recognize the importance of maintaining sterility and containment in their processes.2

ARES Scientific’s pharmacy isolator, the Baker ChemoSHIELD®, is a Compounding Aseptic Containment Isolator (CACI) specifically designed for handling hazardous chemotherapy agents and IV admixtures while minimizing the risk of harm to pharmacy personnel.

Some of the key features of the ChemoSHIELD® include:

- Airtight damper

- HEPA-filtered airflow is better than ISO Class 5

- Negative pressure

- Spacious chamber

- Supplied gloves are ambidextrous and meet ASTM D6978

- UPLA filters

Contact a member of ARES Scientific today to learn more about how the ChemoSHIELD® could be the optimal isolator for your pharmacy.