Introduction to Drying Cannabis Flower

This article is an introduction to a multi-part series on the science of drying cannabis. ARES Scientific’s goal is to provide value to the most experienced grower while giving newer growers knowledge that will increase the quality of their product. We help facilities maximize their productivity and produce the highest quality product possible.

The Goal of Drying and Curing Cannabis

Drying and curing cannabis, when done correctly, preserves as many of the desirable bioavailable compounds in the final product as possible. Optimal drying methods will result in satisfied consumers and build the reputation of the grower’s brand, leading to increased revenue.

I once had an experienced grower tell me that drying and curing cannabis is “as much of an art form as growing cannabis.” Experienced growers love tradition and often need help recognizing areas where they may lose product potency, taste, color, smell, and smokability. A slight change to the drying process can be the difference between being a good brand and a legendary label.

The Balancing Act in Drying Cannabis

Harvesting top-quality commercial cannabis is a sensitive balance between delicacy and efficiency. Growers want to maximize their bud quality while delivering their product on time. Each grower will have a unique approach to their drying operation driven by many factors, including size, staffing, and facility drying conditions. A drying regime that maximizes efficiency is necessary if a large grow operation wants to stagger multiple harvests for continuous output. Conversely, an artisan grower or operation growing one crop at a time may be able to dedicate additional care to handling and extending drying time.

What is the Proper Drying Process?

The proper drying process preserves as many bioactive compounds in the buds as possible because these compounds determine potency, taste, smell, and medical benefits to end users. Scientific studies have shown more than 550 bioactive compounds in cannabis buds at the time of harvest. Further analysis has demonstrated the presence of at least 125 cannabinoids and almost 200 non-cannabinoid substances like flavonoids, phenols, terpenes, and alkaloids in cannabis flowers.

In a suboptimal drying process, more bioactive compounds are lost, decreasing cannabis flower quality. Poor flower quality leads to lower future sales, damage to the grower’s brand ,and a worse experience for the user.

Factors in optimizing the drying process

Handling Can Destroy Potency

Delicate handling is critical in preserving cannabis potency levels post-harvest. Rough handling or shaking of the plant causes trichomes to fall off, which reduces potency. While this may seem obvious, many growers have steps in their drying process that are unknowingly causing a mechanical loss of potency. Recent studies have shown that potency reduction from rough handling is much higher than was previously thought.

Temperature and Humidity

Transpiration is the process of water moving through a plant and its evaporation from leaves, stems, and flowers. When a cannabis plant grows, transpiration is a continuous process that starts with water uptake via the root system. However, when the plant is harvested, the root system is no longer present to take up water.

The foundation for the drying process is controlling the transpiration or water loss rate of the remaining water in a plant post-harvest. Remember, the plant can no longer take up new water, but the rate at which it loses its remaining water determines the quality of the final flower.

The drying room’s temperature and humidity will determine the water loss rate in harvested plants. Drying room temperature and humidity determines how much water vapor the air can hold. Lower temperatures will result in slower water loss by evaporation/transpiration. Higher humidity will also lead to slower water loss.

If the air has the potential to hold a large amount of moisture, the plant will give its moisture to the air and dry out quickly. For example, take the mechanism of sweating:When someone sweats on a hot, dry day, the sweat will evaporate quickly. However, the sweat will take much longer to evaporate if they sweat on a cooler, humid day.

What Is Water Activity, and Why Is It So Important?

When drying cannabis, growers want to control the evaporation rate so that buds don’t dry too quickly because quick drying causes the loss of bioactive compounds. However, there is a considerable risk with drying too slowly that growers can underestimate. Bacteria, mold, and fungus also thrive in the drying environment. The entire crop can be lost to pathogens if these harmful organisms flourish in a drying room.

Water activity is the amount of water in your product that bacteria, mold, or yeast can use to multiply and destroy your crops. Once the water activity falls below a certain level, these organisms can no longer proliferate, and your buds are shelf-stable. Water activity can seem complicated, but it is used in the food industry to determine the shelf stability of foods. It is also used to determine the shelf stability of cannabis scientifically. The FDA provides information about water activity here..

Conclusion

The goal of drying and curing cannabis is to maximize the quality of your product for the end user, including taste, smell, color, potency, and smokability. Optimal cannabis quality is accomplished by drying at a rate that maximizes the preservation of bioavailable compounds while inhibiting the growth of harmful pathogens.

If the plant dries too quickly or is handled roughly, many of these compounds are lost, leading to a poor product. Conversely, if the plant dries too slowly, the water activity level promotes the growth of pathogens that can ruin the harvest. The optimal drying procedure balances all of the drying factors for an excellent final product.

ARES Scientific is your cannabis drying resource and equipment supplier

At ARES Scientific, we have extensive experience working with the pharmaceutical industry and food manufacturers, which demand the highest quality control levels and product production materials. We bring this expertise into the cannabis industry by providing you with products designed to perform under commercial demands and leave no harmful trace elements . We represent the highest quality manufacturers with extensive track records for customer satisfaction.

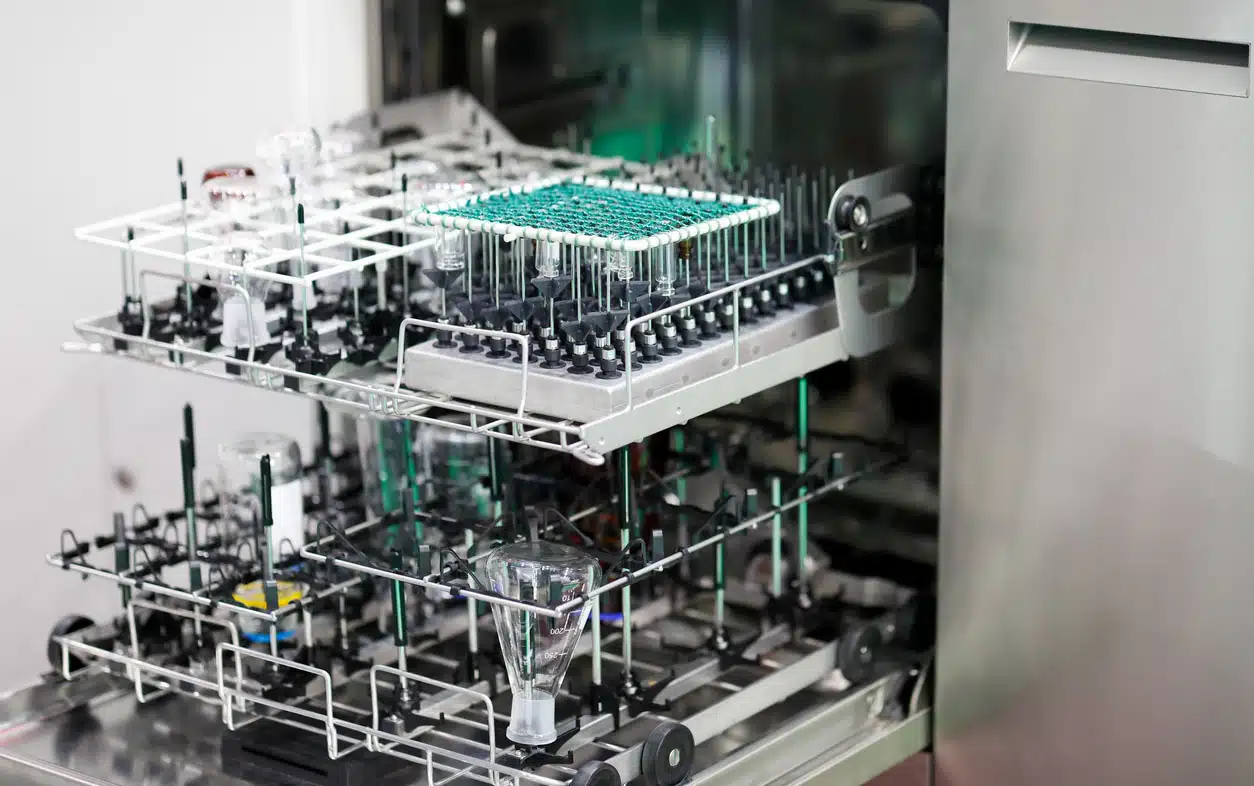

One of our most popular products for cannabis drying is our Metro WavDri trays. These trays reduce your drying space requirements while providing an optimal drying environment. They are food-contact certified and contain Microban to help prevent mold, yeast, and bacteria growth and spread. Finally, the trays are washable up to 212 degrees Fahrenheit for easy and thorough cleaning.

Our Ohaus scales and balances are the gold standard for commercial use. We carry scales with working weight ranges applicable from the smallest formulations to large-scale bulk product weighing. In addition, we have NTEP-certified scales required for certified trade and commerce.

We also carry the finest drying ovens, vacuum drying ovens, commercial washers, custom storage and shelving for nurseries and grows, moisture content and pH meters, plus many more.

Contact us today for information on our products or questions about your facility.