Objective:

This article aims to assist lab professionals in choosing between a Class II A2 and Class II B2 biological safety cabinet for their laboratory, a common consideration when investing in a Class II biosafety safety cabinet. By the end of this piece, you will understand which cabinet type aligns best with your lab’s research requirements to improve your laboratory safety measures, protecting both personnel and the environment from potential hazards.

Introduction:

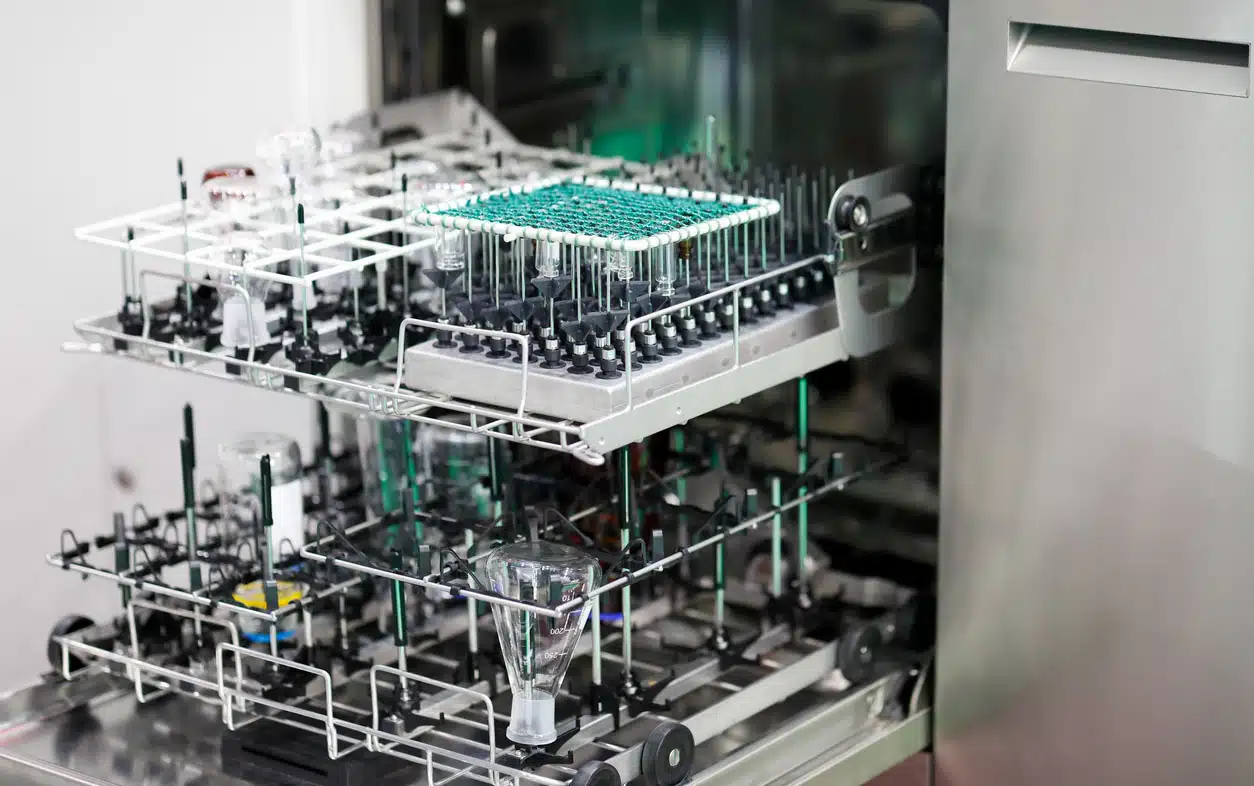

Tracing its origins back to 1909, the biosafety cabinet (BSC) was initially conceived as a ventilated hood to curb tuberculosis infection during tuberculin preparation. The concept of an enclosed cabinet emerged in scientific literature in 1943, and by the early 1950s, advanced containment cabinet technology was in use at the U.S. Army Biological Laboratories in Fort Detrick, Maryland. BSCs are now a standard feature in laboratories around the world, acting as a critical line of defense against an array of potential contaminants. However, understanding the terms safety and control of airborne contamination requires contextual knowledge. It raises questions like, what’s an acceptable degree of exposure? And how can we compare the effectiveness of BSCs from various manufacturers?

Running a modern healthcare, biological, chemical, or pharmaceutical lab demands a deep understanding of the key equipment used regularly. A lab manager’s efficiency often rests on their comprehensive knowledge about each device, including deployment implications, maintenance, repair, and replacement strategies.

NSF International, a leading standards development organization, aided in developing standards and classifications for BSCs. These standards are based on the protection level each BSC is designed to deliver. A solution ideal for one lab might be excessive or inadequate for another, making these minimum standards essential knowledge for lab managers and safety officers to assess what they can rely on.

Understanding the Classes of Biological Safety Cabinets

There are three primary types of BSCs in common usage:

Class I: This cabinet type can recirculate air back into the laboratory or exhaust it through a facility’s HVAC system. It leverages negative pressure from an interior blower motor or the external exhaust system, creating an air barrier at the cabinet’s front. The cabinet inhales air from a supply opening, typically located at the front, and the exhausted air passes through a HEPA filter. Class I cabinets are tailored for low-to-moderate-risk biological substances and focus on personnel and environmental protection, rather than product protection within the cabinet.

Class II: Like Class I, Class II cabinets have a partially open front for worker access and use negative pressure to prevent air movement through a supply opening and the access panel. The main distinction between the two classes lies in the air barrier mechanism. A Class II cabinet creates a vacuum using an airfoil directing air beneath the work surface, filtering the internal workspace’s air supply. By using laminar airflow, it eliminates turbulence and reduces cross-contamination risk within the cabinet. Depending on the cabinet’s subtype, the air may be recirculated back into the workspace, exhausted, or a combination of both.

Class III: These entirely enclosed cabinets are designed for biosafety level 4 pathogens, offering extensive protection for both personnel and the environment. Users interact with the enclosed workspace through mounted gloves that penetrate a non-open window, ensuring complete containment of potential biohazards.

Class II Biological Safety Cabinets Explained:

Class II biosafety cabinets, widely used in labs, play a critical role in preventing airborne contamination, particularly by particulate matter. These cabinets shield lab technicians from pathogens like viruses, spores, and bacteria, ensuring their safety and mitigating liability for the organization. Class II BSCs also protect ongoing lab work by preventing cross-contamination, which saves time, effort, and allows personnel to maintain schedules. These cabinets safeguard the overall lab environment, as well, by containing potential contaminants and filtering them from the air released, preventing further contamination risks. These benefits and protections have made BSCs an essential safety and risk management tool in all facilities handling biological materials, from healthcare providers to pharmaceutical manufacturers.

Class II BSCs utilize the principles of fluid dynamics to maintain a contamination-free zone while enabling personnel to perform necessary tasks. These cabinets might appear passive, because their chief tool, air, is invisible. To appreciate their containment effectiveness, one needs to understand the basic physics involved.

The Bernoulli Principle, espoused by Swiss mathematician and physicist Daniel Bernoulli in the 18th century, explains how these cabinets work. The principle states that fluid pressure, fluid speed, and channel cross-section are interrelated, meaning when the channel size decreases, the fluid—in this case, air—speed increases and vice versa. The Bernoulli Principle is what allows a Class II BSC to safeguard personnel, products, and the environment.

The BSC, essentially a box with a blower moving air within, features a transparent panel for visibility and an opening for technicians to conduct work. This opening, known as the window sash, along with a blower-driven air column, creates a negative-pressure area compared to the lab room’s air pressure. This design ensures air flows from the lab environment into the cabinet, forming a moving air curtain that prevents outward airflow, provided personnel use slow and careful hand movements to minimize turbulence and maintain the air curtain.

Depending on the BSC type and nature of work, filtered air might either be reintroduced into the lab or vented outside via the building’s exhaust system. However, the HEPA filters used in these systems cannot eliminate volatile toxic chemical vapors or radionuclides. Non-exhausted air is recirculated through the supply HEPA filter and back into the workspace, perpetuating the cycle.

Choosing between Class II A2 and Class II B2 Biosafety Cabinets (BSCs):

Determining the appropriate Class II BSC for your lab – whether it’s Type A2 or B2 – is an important decision that hinges on understanding their fundamental differences and the specific needs of your lab. Class II BSCs are commonly employed for microbiological studies, cell culture, pharmaceutical procedures, and toxicology. However, Type A2 and B2 have distinguishing features, primarily related to how each manages the exhaust airflow post high-efficiency filtration.

Class II A2 BSCs recycle the exhaust airflow back into the lab after filtration, maintaining a 30 percent efflux and 70 percent internal circulation. These cabinets are ideal for labs working with biological agents at levels 1, 2, and 3, as the HEPA filters offer robust protection against cross-contamination. However, A2 cabinets aren’t designed to manage chemical fumes due to the reintroduction of exhaust airflow into the lab.

In contrast, Class II B2 BSCs direct their filtered exhaust airflow outdoors entirely, maintaining 100 percent efflux with zero internal circulation. These units are better suited for work involving protection from both biological particles and fumes, such as those produced by radioactive or toxic gases. So, if your lab generates such gases, a B2 cabinet would be more suitable.

However, B2 cabinets necessitate further considerations. They require a well-ventilated laboratory, as inadequate ventilation could decrease the cabinet’s wind speed, compromising its capacity. Also, their high air exchange rate may impact the lab’s temperature, potentially causing discomfort during extreme weather conditions.

Both B2 and A2 cabinets must have a minimum intake air velocity of 100 feet per minute to ensure adequate performance. They are designed to prevent contamination spread by keeping biologically contaminated ducts and plenums under negative pressure.

While Class II A1, A2, B1, and B2 BSCs all offer personnel, product, and environmental protection, only B1 and B2 cabinets guard against vapors and gases. The B1 cabinet employs a recirculating system, and must be hard-connected to an exhaust system, while the B2 cabinet, without air recirculation, must also be hard-connected to a facility’s exhaust system, providing protection when chemical effluent is present.

In summary, Types A2 and B2 cabinets both are vital for biological safety and preventing particulate contamination. Your choice between these will depend on your experiments, potential gas production, and specific lab conditions. Ensure thorough consideration of all factors to select the right safety cabinet for a safe, efficient lab environment.

Conclusive Guide for Selecting a Class II Type A2 or B2 BSC:

- Consider Your Experiment Type: If your experiments only involve biological agents at levels 1, 2, and 3 and don’t generate chemical fumes, the Class II A2 BSC, which recycles 70 percent of the air back into the lab, should suffice.

- Evaluate the Potential for Chemical Fumes: If your work involves the production of chemical fumes, such as those from radioactive or toxic gases, you should opt for the Class II B2 BSC, which exhausts 100 percent of its air outdoors.

- Assess Ventilation Capabilities: Remember, B2 cabinets require a well-ventilated laboratory. If your lab lacks proper ventilation, it could affect the cabinet’s wind speed, thereby compromising its safety.

- Think About the Lab’s Climate Control: A B2 cabinet can influence the lab’s temperature due to its high air exchange rate. If your lab doesn’t have an effective climate control system, you might experience discomfort in extreme weather conditions.

- Check for Exhaust System Compatibility: B1 and B2 cabinets must be hard-connected to an exhaust system due to their operational design. Ensure your facility’s exhaust system is compatible.

- Evaluate the Air Intake Velocity: Regardless of whether you choose a B2 or A2 cabinet, it must maintain a minimum intake air velocity of 100 feet per minute to function correctly.

- Analyze Financial Implications: Lastly, take into account installation costs, energy usage, and potential maintenance costs. While safety is paramount, your budget will also impact your choice.

By considering these factors, you can make an informed decision about whether a Class II A2 or B2 BSC is the right choice for your laboratory.

Supporting You with ARES Scientific: Your Destination for Quality Biological Safety Cabinets:

At ARES Scientific, we pride ourselves on offering an extensive selection of top-tier biological safety cabinets from industry-leading manufacturers. Our diverse product range accommodates various research and laboratory requirements, whether you need basic BSCs or specialized units engineered for compounding hazardous materials with exceptional precision.

Our commitment extends beyond product offerings. Our experienced sales team is on hand to provide personalized assistance, leveraging their in-depth understanding of our product range and industry expertise. They’ll thoroughly assess your specific research needs, facility setup, and safety protocols to recommend the BSC that’s optimal for you.

We understand that the right BSC is crucial for maintaining the integrity of your research and safeguarding your lab personnel. Hence, we prioritize understanding your unique context to provide tailored solutions that elevate your lab’s safety, efficiency, and productivity.

Trust ARES Scientific for your biological safety cabinet needs. With our wide array of premium products and commitment to customer service, we’re equipped to enhance the safety and success of your lab environment. Boost your lab’s potential with our unparalleled expertise in biological safety solutions.