As research and medical procedures continue to advance in the world of vivariums, the use of volatile anesthetic gases such as isoflurane, nitrous oxide, desflurane, and sevoflurane is increasing. These waste anesthetic gases (WAGs) can pose occupational hazards if not managed properly. Therefore, it’s crucial to explore how to minimize exposure to WAGs in vivarium environments.

Understanding Waste Anesthetic Gases (WAGs)

WAGs are the leftover anesthetic gases released into the environment during medical or surgical procedures in vivariums. Exposure to these gases can result in adverse health effects. Therefore, workers must ensure they operate in well-ventilated areas where air is fully exhausted and not recirculated.

The following engineering controls should be used to control human exposure to WAGs – in order of preference:

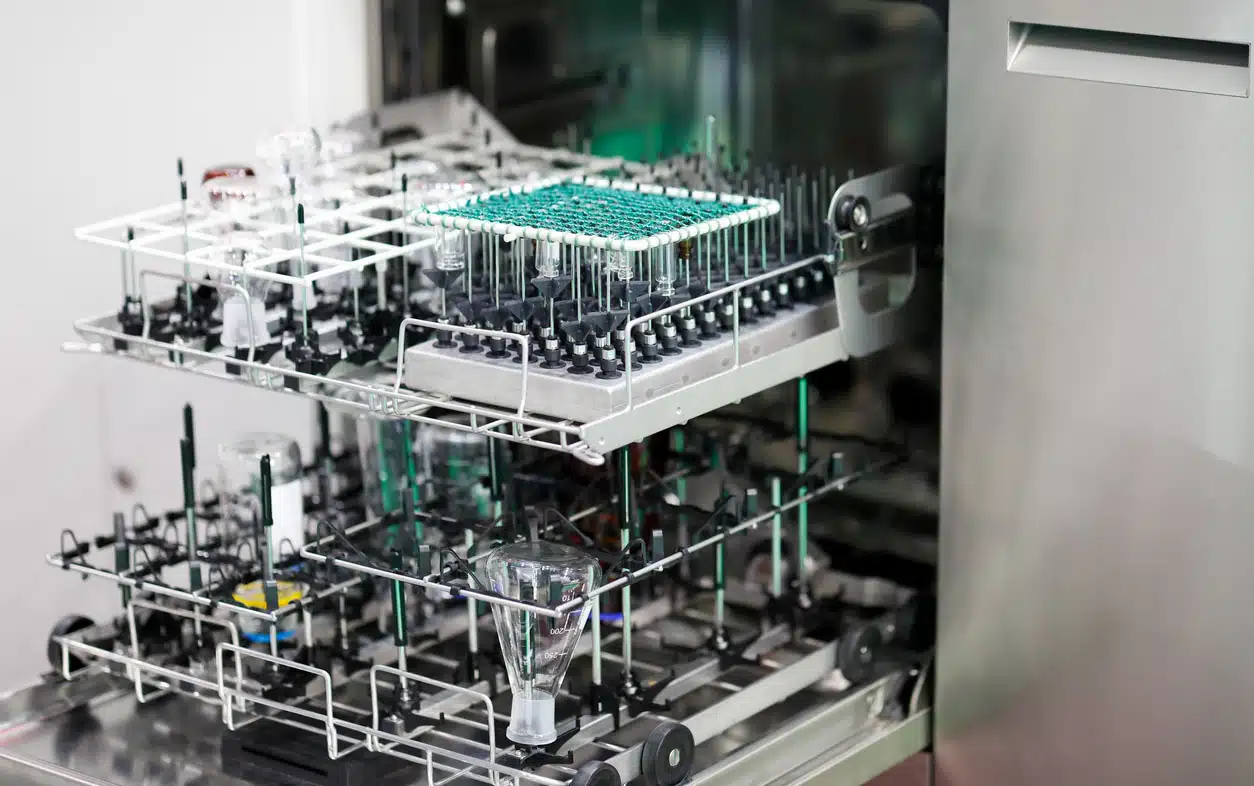

- Chemical Fume Hood or Certified Class II Type B1 or B2 Biosafety Cabinets: A certified Class II Type B1 (thimble ducted) or Class II Type B2 (hard-ducted) biosafety cabinet or a chemical fume hood is the best option for reducing exposure to WAGs. These cabinets ensure top-notch WAG capture. Using such controls allows for the highest level of safety, ensuring that the WAGs are fully contained and do not present a hazard to workers.

- Snorkel Exhaust, Backdraft or Downdraft Table: If a biosafety cabinet or fume hood is not available, other local exhaust ventilation systems such as snorkel exhaust or backdraft or downdraft tables can be used. These systems, while not as efficient as a biosafety cabinet, can still effectively capture and contain WAGs.

- Active Scavenging Device: Active scavenging devices, such as a nose cone or intubation, are good options for controlling WAGs. These devices use an air cleaning extraction system with an activated charcoal adsorption unit to actively scavenge WAGs. However, house vacuum lines should not be used for active scavenging unless approved by the facility’s Department of Environmental Health and Safety .

- Passive Scavenging: Passive scavenging should be used only when the above engineering controls are not feasible. These systems use positive pressure from the anesthesia machine and the anesthetized animal’s exhalation to push WAGs into gas adsorption units, such as canisters. However, this method is less effective and may result in WAG leakage into the work area. Moreover, charcoal adsorption units are not suitable for use with nitrous oxide.

Anesthetic Equipment Maintenance

Regular maintenance of anesthesia machines is also crucial in the management of WAGs. These machines should be serviced annually or as per the manufacturer’s instructions. Frequent checks of fittings, tubing, and connections are necessary, with immediate replacement of seals and damaged components as required. Additionally, a refrigerant leak detector or soap bubble test can be periodically used to check for gas leaks.

In conclusion, maintaining a safe and healthy work environment in vivariums requires vigilance and effective management of WAGs. The use of Class II Biological Safety Cabinets, along with other scavenging methods, can significantly minimize the risks associated with these anesthetic gases. However, consistent equipment maintenance is vital to ensure the effectiveness of these systems. Combining these strategies will minimize the potential occupational hazards of WAGs.

WAG Protection from Different Classes of Biosafety Cabinets

A BSC offers gas containment only when it’s exhausted through a hard or a canopy connection. Here’s a quick review of the different types of BSCs and their configurations regarding exhausting and gas protection:

Class II, Type A1 and Type A2 (without canopy or thimble) offer 70 percent recirculation and 30 percent room circulation, with no anesthetic gas protection.

Class II, Type A2 (with canopy or thimble) provides the same recirculation ratio but with gas protection.

Class II, Type B1 offers 30 percent recirculation and 70 percent hard exhaust with gas protection.

Class II, Type B2 provides no recirculation and 100 percent hard exhaust, ensuring full gas protection.

BSC Class II, Type A1 and Type A2 for Minimizing Exposure to Waste Anesthetic Gases

When the BSC is room re-circulated, like Class II Type A1 and Type A2 without canopy or thimble, no gas protection is provided. This limitation could present significant challenges, especially when the vivarium exclusively uses room recirculated BSCs. However, one possible workaround is to install the anesthetic gas delivery and scavenging system within the BSC. The use of BSCs in this manner doesn’t increase the negligible release level of anesthetic gas. Moreover, additional service ports through the BSC’s work zone wall can help to aid the delivery and the scavenging system, if necessary.

When a scavenging system isn’t available, one alternative is to scavenge the room’s recirculation portion or exhaust airflow of the BSC. To accomplish this, a charcoal filter with sufficient efficiency should be fitted over the BSC’s exhaust airflow. To ensure the containment performance of the BSC is not affected, a supplemental blower, interlocked with the BSC’s blower, should be used to maintain the exhaust volume rate.

Tests have shown that a charcoal filter blower (CFB) module, when attached over the exhaust HEPA filter of a room recirculated Class II Type A2 BSC, can achieve a 70 percent collection efficiency of isoflurane gas. The results of the tests showed a considerable reduction in isoflurane concentration from 3.5 ppm to 0.98 ppm at a 5 percent isoflurane mixture when using the CFB module. Additionally, a steady-state gas room concentration level also showed a significant reduction from 8.3 ppm to 2.5 ppm at a 5 percent isoflurane mixture.

While these results demonstrate the potential benefits of a CFB module, several risk factors need to be evaluated. These include the room’s design, size, number of air changes, and the isoflurane delivery process.

BSC Class II, Type B1 and Type B2 for Minimizing Exposure to Waste Anesthetic Gases

The Class II Type B1 and especially Type B2 Biological Safety Cabinets (BSCs) have emerged as the best choice for minimizing exposure to WAGs. Class II Type B1 and B2 BSCs are containment devices designed to offer protection to laboratory personnel, the environment, and the product within the cabinet. They provide an effective barrier against biohazardous and volatile chemical materials through HEPA filters and a unique airflow system.

Class II Type B1 Biological Safety Cabinets:

In Class II Type B1 BSCs, approximately 70 percent of the air is recirculated through the HEPA filter, while the remaining 30 percent is exhausted out of the building through a dedicated duct. This makes them relatively effective at controlling WAGs, especially if used in conjunction with other safety measures, such as appropriate personal protective equipment (PPE) and procedural controls.

Class II Type B2 Biological Safety Cabinets – The Preferred Choice

Class II Type B2 BSCs, on the other hand, do not recirculate air but exhaust 100 percent of it outside the building after HEPA filtration. This hard-ducting system and the absence of recirculated air make them the preferred choice when dealing with volatile chemicals and gases, including WAGs.

Why Class II Type B2 BSCs are the Best for Minimizing Exposure to WAGs:

There are several reasons why Class II Type B2 BSCs are considered the optimal solution for minimizing exposure to WAGs:

- Effective Containment: The full exhaust of filtered air outside the building ensures a high degree of containment for volatile and toxic substances, which reduces the risk of exposure to WAGs.

- Excellent Safety Features: They are equipped with safety features like the air curtain, which prevents escape of the gases into the laboratory environment, and the pressure gauge, which provides constant feedback on cabinet performance.

- Versatility: Their capacity to handle a wide range of biological and chemical hazards makes them ideal for a variety of applications where WAGs are produced.

- Compliance with Regulations: These cabinets are designed to meet the strict safety standards of the NSF/ANSI 49, which ensures that they offer reliable protection against WAGs.

In conclusion, for laboratories dealing with waste anesthetic gases, the selection of an appropriate containment device is vital. While Class II Type B1 BSCs can offer some level of protection, Class II Type B2 BSCs, with their full-exhaust capabilities and safety features, are the superior choice for minimizing exposure to WAGs. Their versatility, effective containment, and adherence to safety regulations make them the optimal solution for a safe and efficient laboratory environment.

ARES Scientific: The Leading Distributor in Protecting Vivariums Against Waste Anesthetic Gases

When it comes to safeguarding vivarium environments from waste anesthetic gases (WAGs), ARES Scientific stands out as the foremost distributor in the field. The company’s commitment to delivering high-quality, reliable solutions to vivariums across the nation has solidified its reputation as a trusted expert in the sector.

Exceptional Product Portfolio

ARES Scientific boasts a comprehensive range of products designed to mitigate the risks associated with WAGs. Key among these offerings are the Class II Type B2 biological safety cabinets (BSCs). As established in previous discussions, these cabinets are highly effective in controlling WAGs exposure due to their 100 percent exhaust feature. ARES Scientific’s product portfolio also includes an array of other protective devices and solutions that cater to the unique needs of each vivarium.

Expertise and Experience

With many years of combined experience under their belt, ARES Scientific equipment experts have accrued invaluable knowledge and understanding of vivarium environments and the risks posed by WAGs. This level of expertise enables them to offer not only the best products but also sound advice and guidance, ensuring each client makes the most informed decisions for their unique situations.

Focus on Quality and Safety

ARES Scientific is steadfastly committed to providing products that meet the highest quality and safety standards. All its distributed BSCs and other protective equipment conform to stringent safety guidelines, including NSF/ANSI 49, ensuring clients receive reliable and efficient solutions for controlling WAG exposure.

Customer-Centric Approach

ARES Scientific takes a customer-centric approach to its business, prioritizing the specific needs of each client. The team of equipment specialists works closely with clients to understand their unique challenges and deliver tailored solutions. This approach ensures every vivarium receives the most effective and practical equipment for their specific WAG management needs.

Comprehensive Support and Training

In addition to providing high-quality products, ARES Scientific offers comprehensive support and training to its clients. Its team of experts provides guidance on the correct installation, use, and maintenance of its distributed equipment, ensuring customers can effectively manage WAGs in their vivarium. This level of ongoing support underscores ARES Scientific’s commitment to customer satisfaction and safety.

Reliable After-Sales Services

Post-purchase, ARES Scientific continues to offer exceptional service, including regular maintenance checks and prompt responses to any customer concerns. This commitment to after-sales service helps to ensure the longevity and efficacy of their products, further reinforcing their reputation as a trusted distributor.

In conclusion, ARES Scientific’s exceptional product portfolio, industry expertise, commitment to quality and safety, customer-centric approach, comprehensive training, and reliable after-sales services make them the go-to expert distributor for protecting vivariums against waste anesthetic gases. Their dedication to providing reliable and effective solutions to WAG management challenges solidifies their position as a leader in the field.

*Always consult your facility’s safety department or appropriate professionals before using waste anesthetic gases (WAGs) in vivariums. Safety protocols and regulations may vary, and it is essential to ensure proper management and minimize potential hazards related to WAGs. This article provides general information and does not replace personalized advice from qualified experts.