Hydrogen peroxide (H₂O₂) is a powerful sterilizing agent that finds usage across numerous industries — including healthcare, food preparation, and life sciences — due to its ability to combat microbial contamination. Two sterilization methods involving hydrogen peroxide include ionized hydrogen peroxide (iHP) and vaporized hydrogen peroxide (VHP). We will critically analyze both these methods to understand their effectiveness and utility for various applications.

Ionized Hydrogen Peroxide (iHP)

Ionized hydrogen peroxide uses 7.8 percent aqueous H₂O₂, which is passed through a plasma arc and dispersed into a treatment chamber as a mist of micron-sized liquid droplets. This approach directly generates hydroxyl radicals that function as active sterilants, thus requiring approximately 5 times lower H₂O₂ concentration than VHP, which utilizes 30 to 35 percent H₂O₂. iHP technology is commercially available in two forms: a handheld sprayer device, known as a “surface unit“, and an environmental unit, known as an “environment system.” The safety profile of iHP is impressive because it decomposes into water, contrasting with sterilization methods like ethylene oxide (EtO), which has potential carcinogenic and toxic effects.

Vaporized Hydrogen Peroxide (VHP)

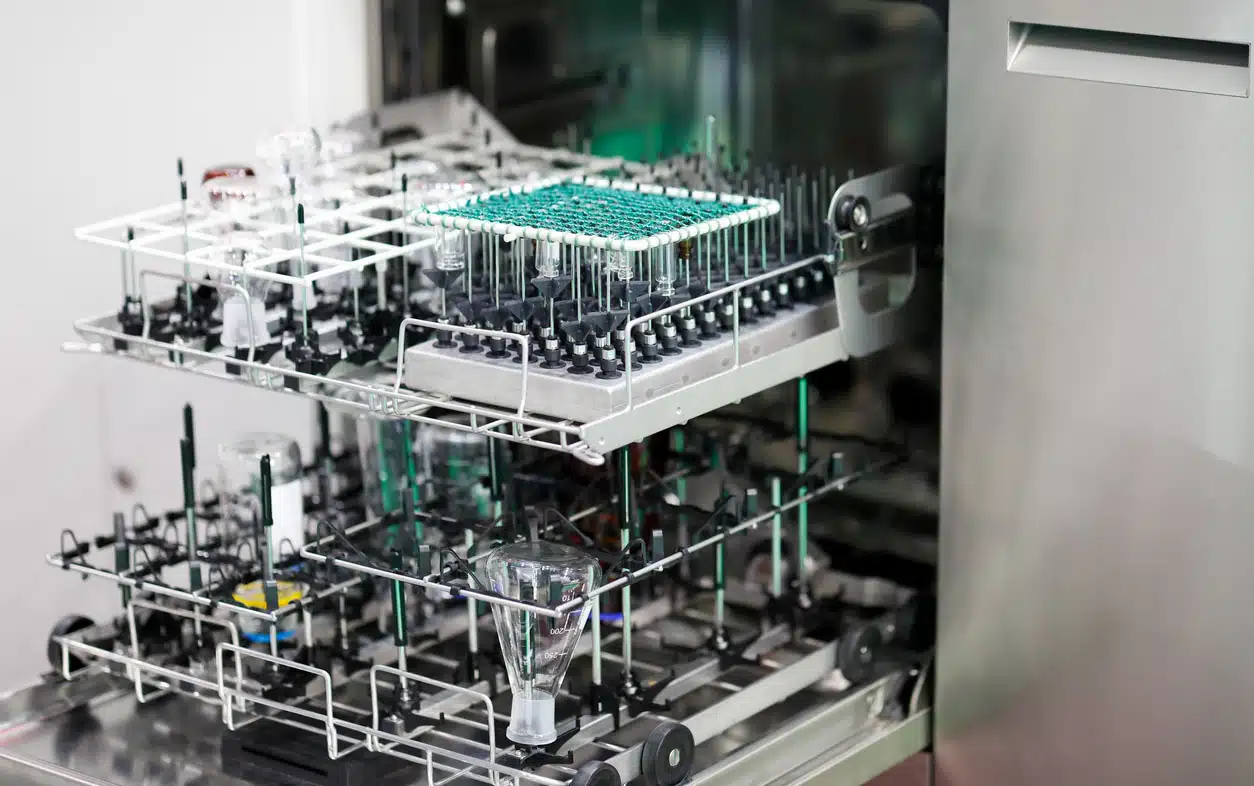

Vaporized hydrogen peroxide uses low-temperature antimicrobial vapor to decontaminate enclosed and sealed spaces, such as laboratory workstations, isolation rooms, and even the interiors of aircraft. Using generators specifically designed for the task, VHP is produced by passing an aqueous hydrogen peroxide solution over a vaporizer. The resulting vapor then circulates at a set concentration in the air. After a defined period, the vapor is either broken down into water and oxygen or vented to the outside air. The U.S. Environmental Protection Agency recognizes VHP as a sterilant. However, using VHP requires careful monitoring due to potential risks, and it is subject to a permissible exposure limit of 1.0 ppm mandated by OSHA. In addition, VHP requires special handling and storage accommodations. Finally, due to the high concentration of VHP (30-35%), material compatibility should be thoroughly considered before using in a facility.

Comparative Efficacy

Both iHP and VHP offer highly effective sterilization processes with unique benefits. iHP is favored for its safety profile and lower H₂O₂ concentration usage. Meanwhile, VHP is recognized for its broad-spectrum antimicrobial activity and ability to decontaminate sealed areas. Despite their impressive disinfection capabilities, careful monitoring is crucial to ensure safety and efficacy. Ultimately, the choice between iHP and VHP depends on the specific requirements of the environment, the type of material that needs sterilization, and the acceptable level of risk.

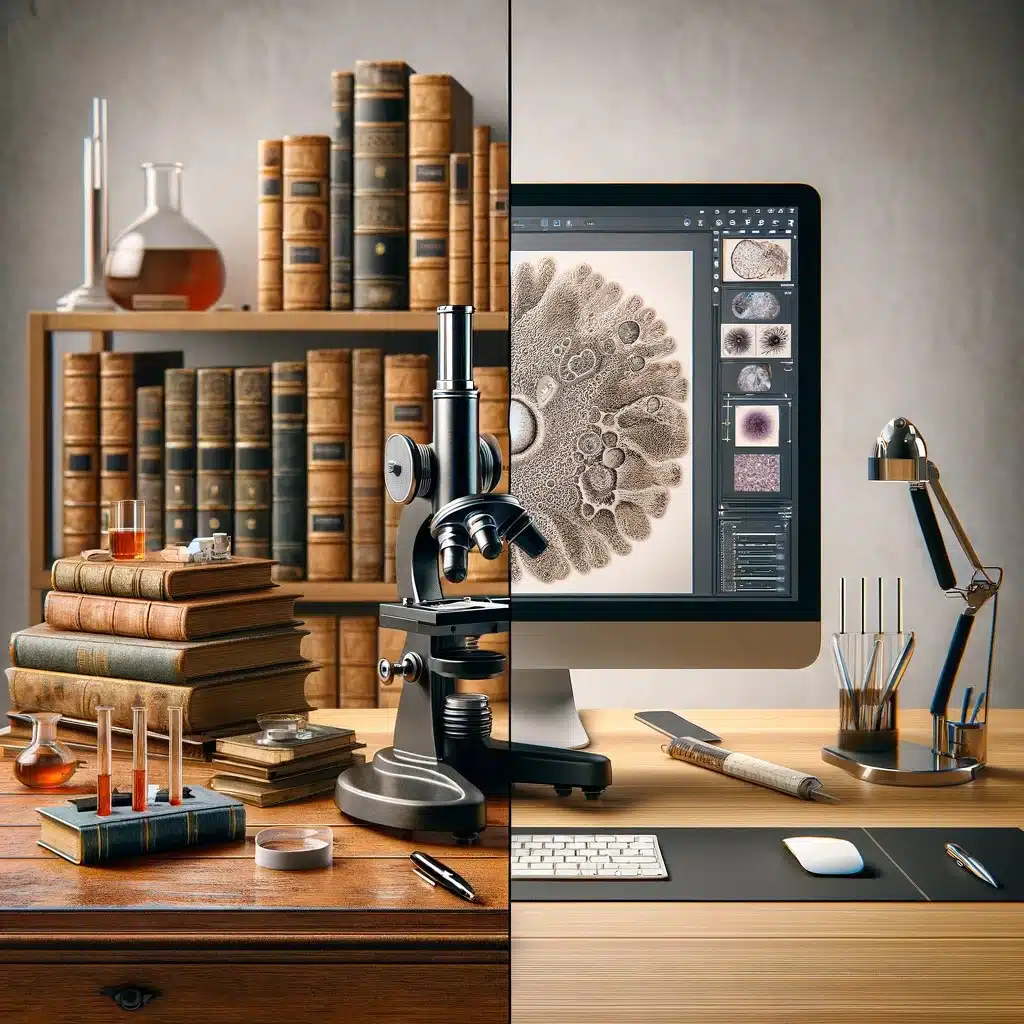

In life science, pharmaceutical manufacturing, and healthcare environments, achieving near-sterile conditions is paramount. Traditional manual cleaning can leave behind a significant portion of surface pathogens, necessitating more effective solutions. While both iHP and VHP technologies can deliver a six-log (99.9999 percent) reduction of pathogens, their implementations differ significantly. The VHP process requires more extended exposure and aeration times, making it less suitable for environments requiring rapid turnover. Conversely, iHP provides a quicker sterilization process, which is highly beneficial in high-throughput settings.

The Benefits of Investing in Ionized Hydrogen Peroxide (IHP)

The importance of sterilization technology cannot be overstated as we continue to navigate the complexities of a world under heightened microbial threats. Ionized hydrogen peroxide stands out for its effectiveness, efficiency, and adaptability. As industries strive to maintain the highest sterilization standards, using iHP offers numerous benefits that set it apart from traditional methods.

High Efficacy

At the heart of iHP’s appeal is its potent sterilizing ability. This technology achieves a six-log (99.9999 percent) reduction of pathogens, effectively eliminating bacteria, viruses, fungi, and molds. It transforms a 7.8 percent hydrogen peroxide solution into ionized particles penetrating even the smallest cracks and crevices. This ensures sterilization, reaching areas that traditional cleaning methods might miss.

Speed and Efficiency

In high-throughput environments, such as healthcare facilities and pharmaceutical manufacturers, time is a critical factor. IHP shines in this aspect, offering a swift sterilization process. The complete cycle, including application, contact, and aeration time, takes just over 75 minutes. This high-speed cycle reduces downtime, enabling a quicker turnover of sterilized areas — an invaluable asset in busy, high-demand settings.

Material-Friendly

Unlike sterilization methods that rely on high concentrations of hydrogen peroxide, like vaporized hydrogen peroxide, iHP uses a significantly lower concentration. This reduces the risk of material corrosion or damage significantly. IHP is non-corrosive to most metals and alloys, plastics, and elastomers, making it a great choice for facilities containing sensitive equipment, electronics, or delicate structures.

Adaptable Application

IHP technology is commercially available in two forms: a handheld sprayer unit for targeted high-touch surfaces and a total-environment fogging system. This adaptability means that iHP can be employed for a broad range of scenarios, from precision-targeted sterilization tasks to large-scale disinfection of entire rooms or spaces.

Improved Safety Profile

The iHP sterilization process results in the formation of harmless byproducts: water and oxygen. Unlike compounds such as ethylene oxide, which produces potentially carcinogenic and toxic residues, iHP’s benign end-products make it a safe choice for operators and the environment.

Economic Advantage

While the upfront cost of an iHP system is usually higher than traditional methods, it can pay for itself due to reduced labor costs and, because it requires less hydrogen peroxide, reduced chemical costs. Moreover, the minimal risk of material damage leads to decreased maintenance and replacement costs for facility equipment.

Conclusion

The collaboration between ARES Scientific and TOMI brings together the expertise and innovation of two industry giants, resulting in a powerful synergy that benefits customers across various sectors. TOMI’s groundbreaking SteraMist™ Binary Ionization Technology (BIT) has proved highly effective in eliminating many pathogens, including viruses, bacteria, and spores. With ARES Scientific’s extensive distribution network and commitment to exceptional customer service, organizations can easily access TOMI’s cutting-edge solutions to safeguard their environments and promote a healthier, safer future.

TOMI SteraMist offers a robust suite of advanced disinfection solutions, tailored to different environmental needs and applications. The SteraMist Environmental System is designed for whole room disinfection, applying a fog of ionized Hydrogen Peroxide (iHP) to eradicate harmful bacteria and viruses from any surface within a room, including high touch, shadowed and difficult-to-reach areas.

The Surface Unit, a handheld point-and-spray misting disinfection device, allows for rapid decontamination and sterilization of small to mid-sized areas. The SteraPak, a backpack model, offers mobility and versatility, allowing the user to traverse through a larger area, perfect for field use, to disinfect hard-to-reach spots, high traffic zones and larger facilities.

In addition to these products, TOMI SteraMist also provides decontamination chambers and custom room solutions for specific settings, offering a high efficacy, rapid kill and strong material compatibility.

Furthermore, ARES Scientific’s authorized distributorship status for TOMI products ensures that customers have complete confidence in the authenticity and reliability of their purchases. By choosing ARES Scientific, businesses and institutions gain access to genuine TOMI products backed by world-class technical support and training programs.

As the demand for advanced disinfection and decontamination solutions continues to grow, ARES Scientific and TOMI are well-positioned to meet and exceed these expectations. Together, they provide a winning combination of innovation, expertise, and reliability, empowering organizations to create healthier and safer environments for their customers, employees, and communities.