To better protect precious or irreplaceable patient samples, safeguard expensive and sensitive vaccines/medications, or store reagents and controls that are critical to patient care, the adoption of Medical Grade equipment continues to increase in prevalence. Although there are many vendors that market their equipment as Medical Grade, there is no standard industry definition that dictates performance or features. In addition, terms like “Pharmaceutical Grade” or “Purpose Built” are also used interchangeably with Medical Grade when applying to cold storage options. These issues can lead to confusion and uncertainty when making important decisions related to equipment that is critical to the delivery of safe and quality patient care. For this reason, we want to help demystify Medical Grade cold storage.

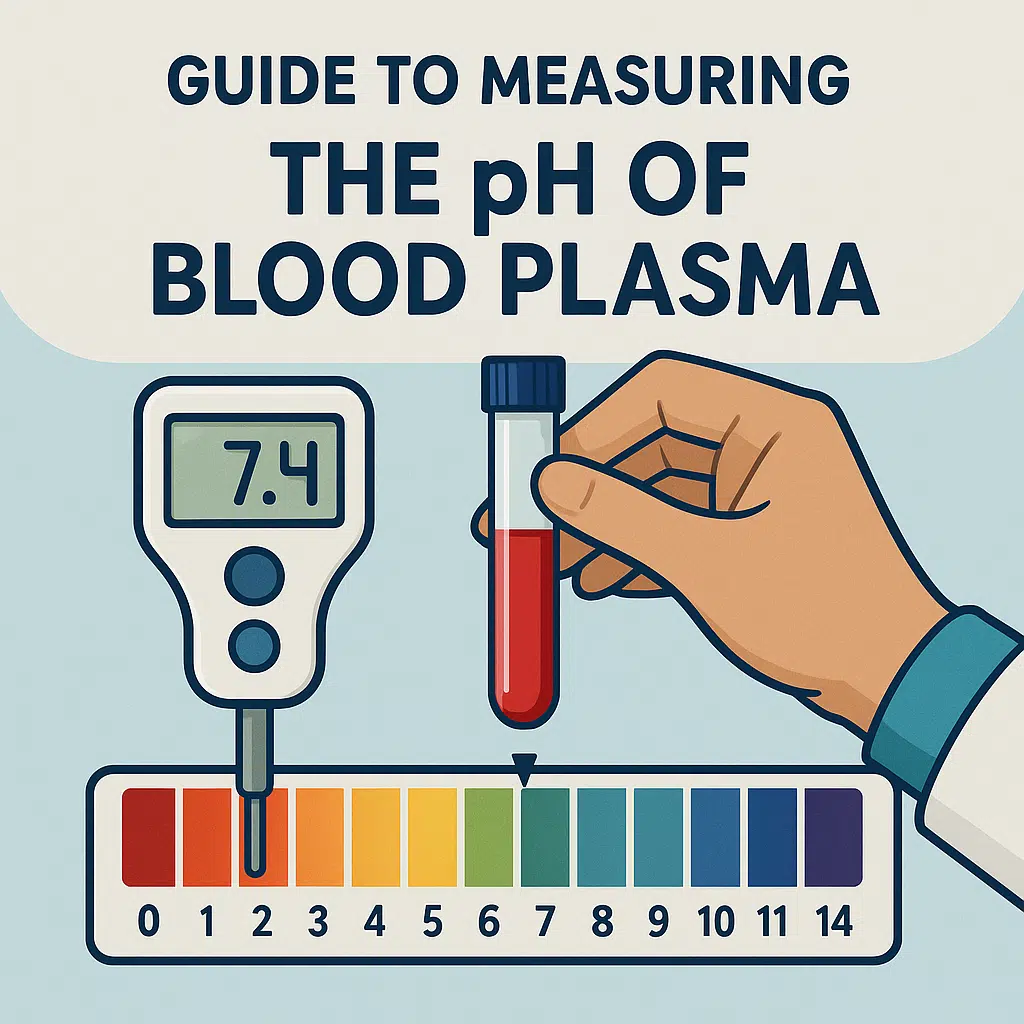

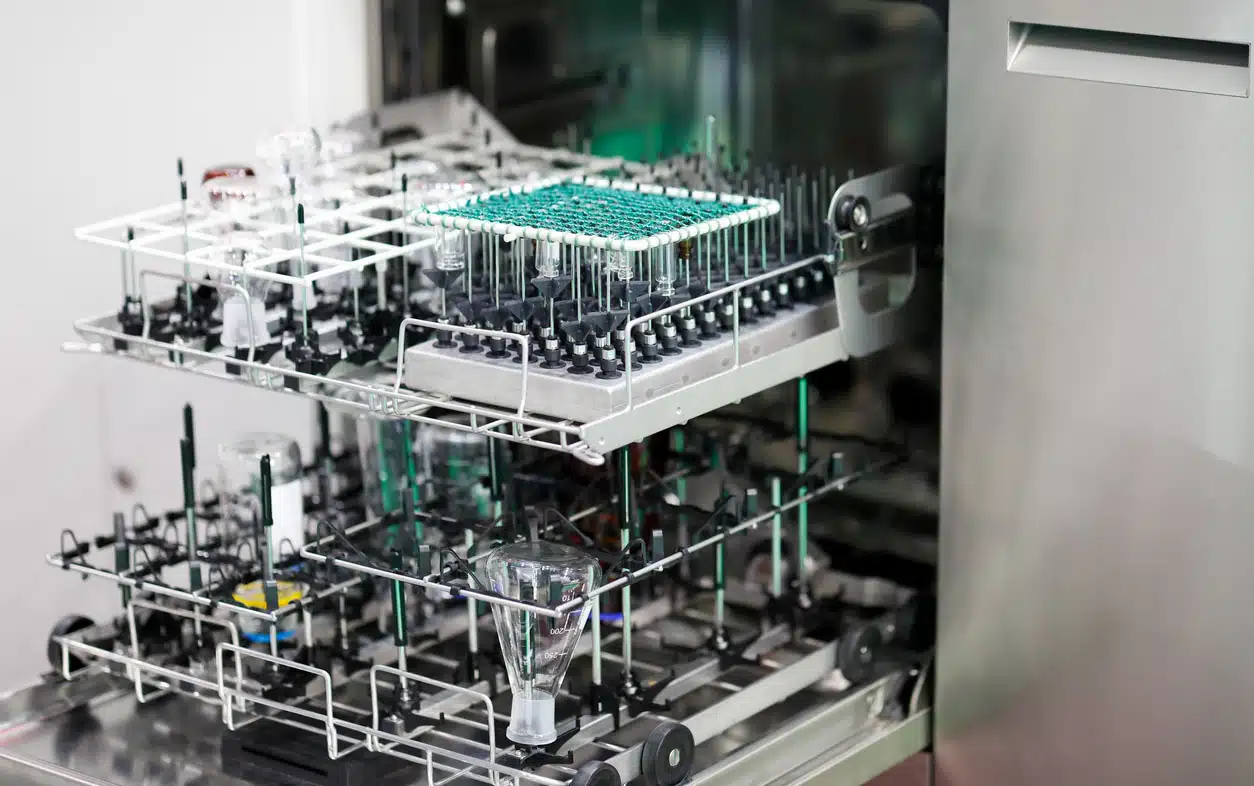

The difference between Medical Grade cold storage and other types of traditional/commercially available units starts with performance. The use of effective forced-air refrigeration not only ensures that all locations within a cabinet maintain a uniform temperature, but will also allow a refrigerator to recover back to set temperature quickly after door openings. Without proper uniformity and recovery, there is risk of exposing sensitive contents to inappropriate storage conditions. Medical Grade units also offer specific features, including microprocessor-based controls and displays, and temperature logging, designed to ensure and monitor precise temperature regulation over time. These units will also commonly include integrated alarms to notify users of risk-causing events; out-of-temperature range, door open, and loss of power alarms are just a few examples. Medical Grade cold storage units will incorporate specially designed drawers or shelves that allow for proper airflow, and some vendors allow for custom storage configuration to best meet the needs of the specific clinical application.

Suppliers of Medical Grade equipment are committed to design and manufacturing quality and will have systems in place to achieve high levels of post-market surveillance and vigilance, as well as support models that are appropriate for clinical customers. FDA-registered suppliers will use ISO 13485 guidance (Quality Management System for Medical Devices) to systemically apply quality across design, manufacturing, marketing, and post-sales support. To help clinical customers meet their specific quality and regulatory needs, Medical Grade equipment suppliers can also offer additional validation services and certificates as part of their cold storage solution.

With an increased focus on laboratory quality and regulatory compliance, healthcare and research labs will continue to make investments in Medical Grade refrigerators. Understanding the differences between Medical Grade and non-Medical Grade equipment for critical clinical applications can be confusing.