Introduction to –80 °C ULT Freezers

Ultra-low temperature (ULT) freezers are vital for preserving sensitive biological samples, vaccines, and research materials—typically at –80 °C or even colder. But not every ULT freezer is created equal. This article explains the science behind how –80 °C ULT freezers work and highlights cutting-edge technologies that maximize energy efficiency. If you’re considering a freezer upgrade or aiming to cut lab energy costs, understanding –80 °C ULT freezers will help you make informed, sustainable choices.

How –80 °C ULT Freezers Work

1. Two-Stage Cascade Compression

Most legacy ULT freezers use a two-stage cascade compression system. Here’s how it works:

- Low-Stage Loop: Uses refrigerants like ethane (R-170) or R-508B to cool an intermediate heat exchanger.

- High-Stage Loop: Uses R-290 (propane) to remove the absorbed heat to ambient room temperature.

- Efficiency: Older units (especially pre-2015) could consume 16–30 kWh/day, dumping large amounts of heat into lab HVAC systems.

2. Free-Piston Stirling Engine

An innovative, oil-free design:

- Mechanism: Uses a sealed helium charge and a linear Stirling engine.

- Advantages: Few moving parts, minimal maintenance, and superior efficiency.

- Performance: Modern Stirling units (~28 ft³) operate between 6.7–9 kWh/day and release up to 75% less room heat.

Core Performance Features Shared Across ULT Freezers

- Vacuum-Insulated Panels (VIPs) or polyurethane foam to reduce thermal ingress.

- Tight inner door seals to minimize air exchange.

- Microprocessor controls with PID logic and alarm systems for optimal stability.

Why Older ULT Freezers Consumed So Much Power

Legacy models with single-speed compressors and outdated refrigerants reacted to every minor temperature fluctuation, drawing over 1 kW continuously. These inefficient units heavily burden HVAC systems and consumed 25–30 kWh/day.

With the introduction of ENERGY STAR® Version 2.0, manufacturers now aim for <0.35 kWh/ft³/day at –75 °C. This equates to roughly 10 kWh/day for a standard 28 ft³ unit, prompting innovations in refrigerant chemistry and compressor design.

Breakthrough Engineering Innovations in Modern ULT Freezers

| Technology | Example Model | Daily Energy Use (kWh) |

|---|---|---|

| Hydrocarbon refrigerants + dual inverter | PHCbi VIP ECO SMART | 5.4 |

| Variable-speed cascade “V-Drive” | Thermo Scientific TSX600 | 8.7–9.3 |

| Dual-circuit TwinCool cascade | Haier DW-86L728/578 BPST | 7.0–8.4 |

| Free-piston Stirling engine | Stirling Ultracold SU780XLE | 6.7–9.0 |

| VIP insulation | PHCbi and Haier | ~30% heat gain reduction |

| Adaptive defrost + fast recovery | Most modern models | <0.8 kWh penalty |

| Low-noise fans | Thermo TSX series (44 dB) | Lower HVAC energy required |

Typical Energy Use Profiles (28 ft³ Models)

- Legacy Cascade (Pre-2015): 16–30 kWh/day

- Conventional New Cascade: 9–12 kWh/day

- PHCbi VIP ECO SMART: 5.4 kWh/day

- Haier TwinCool DW-86L728: 10 kWh/day

- Haier TwinCool DW-86L578: 11 kWh/day

- Stirling Ultracold SU780XLE: 6.2–8.0 kWh/day

- Thermo TSX400/600 at –70 °C: ~5.0 kWh/day

This represents a 60–80% energy reduction compared to decade-old systems.

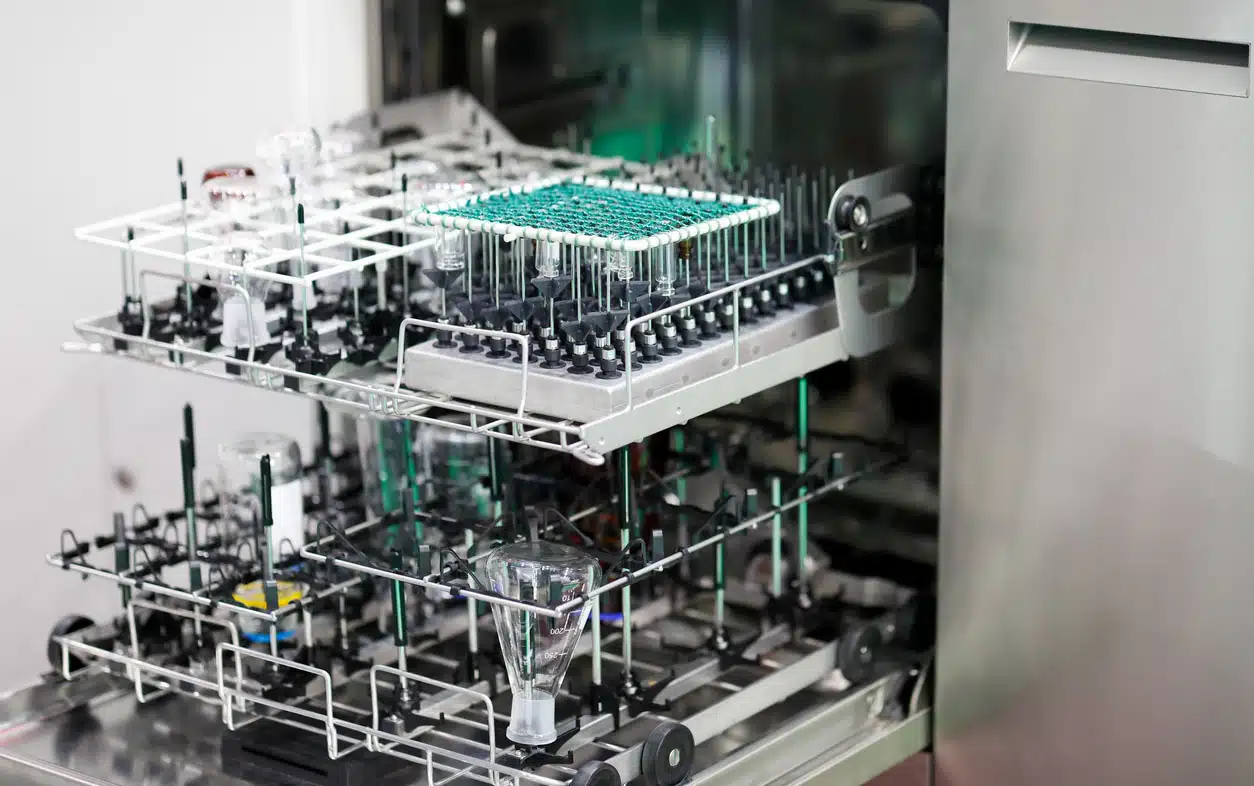

Operational Tips to Maximize ULT Freezer Energy Efficiency

- Raise temperature setpoint to –70 °C if protocols allow (20–30% energy savings).

- Limit door openings to under 30 seconds.

- Regular maintenance: Clean filters quarterly and allow 10 cm clearance for airflow.

- Smart defrosting: Defrost when inventory is low for tighter seal retention.

- Use telemetry and BMS systems to track energy spikes and performance drops.

Energy Efficiency of Haier –80 °C ULT Freezers

Haier’s TwinCool ULT freezers redefine energy-saving standards. For example:

- DW-86L578ST (418L model): Uses only 8.45 kWh/24 hours.

- Dual independent cascade systems: Each capable of reaching –80 °C, allowing redundancy and load balancing.

- Rapid cooling: Recovers to –75 °C within 25 minutes after door opening.

- VIP insulation, double-foamed doors, and optimized seals contribute to superior energy savings.

Additional Benefits of Haier TwinCool Freezers

- 10” touchscreen for control and monitoring.

- Remote access via U-Cool software.

- Multiple alarms, CO₂/LN₂ backup compatibility.

- Low-noise operation (53 dB) and ergonomic design.

- Modular storage and pressure equalization ports.

Why Partner with ARES Scientific

- Expert advice on ULT freezer selection

- Lifecycle cost evaluations (energy, heat load, redundancy)

- Access to ENERGY STAR®/ACT Label data

- Exclusive pricing, trade-in offers, and end-to-end service

Contact ARES Scientific to explore top-tier ULT solutions and get personalized recommendations.

Frequently Asked Questions (FAQs)

1. What is a –80 °C ULT freezer used for?

It’s primarily used for storing biological materials, such as vaccines, enzymes, and tissue samples that require ultra-low temperatures.

2. How much energy do modern ULT freezers consume?

Most modern units consume between 5–9 kWh/day—significantly less than older models that used 16–30 kWh/day.

3. Can raising the temperature to –70 °C affect sample integrity?

Most biological samples remain stable at –70 °C, but always confirm with your lab’s protocol.

4. What refrigerants are used in energy-efficient ULTs?

Modern units use natural hydrocarbons like R-290 (propane) and R-170 (ethane) for lower global warming potential and high performance.

5. How can I tell if my ULT freezer is energy efficient?

Check if it meets ENERGY STAR® criteria and review energy consumption data—ideally under 0.35 kWh/ft³/day.

6. What’s the benefit of a Stirling engine in a ULT freezer?

Stirling engines offer oil-free, highly efficient cooling with minimal moving parts—great for labs seeking lower maintenance and energy use.

Conclusion

The basic science of ultra-low refrigeration hasn’t changed, but its engineering certainly has. Today’s best –80 °C ULT freezers offer powerful cooling at just 5–8 kWh/day. For labs still using legacy models, upgrading isn’t just a cost-saving move—it’s a sustainability commitment. Whether you’re drawn to Stirling systems or advanced cascade designs, understanding –80 °C ULT freezers is your first step toward smarter, greener cold storage.