In the dynamic world of laboratory research and clinical diagnostics, every step that preserves the integrity of your temperature-sensitive materials is vital. Whether you are safeguarding life-saving vaccines, delicate reagents, or irreplaceable biological samples, the quality and reliability of your cold storage solutions can determine the success or failure of your entire project. While it might seem convenient or cost-effective to rely on a consumer-grade refrigerator or freezer to meet these needs, the reality is that such equipment can introduce variables and risks that no research environment can afford.

This comprehensive article will delve into the fundamental differences between laboratory grade/pharmaceutical grade and household refrigerators and freezers, with a particular emphasis on the importance of manual defrost laboratory freezers. We will explore how purpose-built units maintain consistent and uniform temperatures, why defrost cycles matter, the regulatory guidelines and best practices that shape equipment choice, and how selecting the right cold storage solutions ultimately safeguards the integrity of your research, diagnostics, and overall laboratory or pharmacy operations.

The Core Differences Between Household and Laboratory Cold Storage

Design Philosophy and Use Case

Household refrigerators and freezers are engineered for one primary purpose: preserving food safely and cost-effectively for everyday consumers. Their temperature targets, insulation, and internal circulation methods reflect this baseline goal. In contrast, laboratory refrigerators and freezers must maintain much stricter temperature uniformity, stability, and reliability. They store materials such as vaccines, pharmaceuticals, reagents, enzymes, and biological samples—items that can be irreversibly compromised by even slight deviations in temperature.

Precision and Stability

A household refrigerator’s temperature range and control mechanisms are designed with relatively forgiving tolerances. Minor fluctuations have minimal impact on food quality. On the other hand, laboratory equipment must tightly control internal temperatures—often within a narrow band—because many stored substances are highly sensitive. Pharmaceuticals or biological samples, for instance, can lose potency or degrade rapidly if exposed to temperatures just a few degrees outside their recommended storage range. Laboratory units typically incorporate more advanced insulation, microprocessor-based temperature controllers, high-density foam insulation, and robust construction to achieve and maintain these critical conditions.

Uniformity and Airflow

In a household refrigerator, cold air often settles unevenly, resulting in temperature gradients—colder at the top, warmer at the bottom, or vice versa. Such uneven temperatures are acceptable for food storage but pose a serious problem for laboratory samples. Laboratory refrigerators and freezers employ advanced air distribution systems (in many cases, forced-air circulation) to maintain uniform internal temperatures. Units designed for sensitive storage often verify their performance using numerous test probes placed strategically throughout the cabinet to ensure uniformity and compliance with stringent storage standards.

Manual vs. Auto Defrost: Why It Matters in the Laboratory

Auto (Frost-Free) Defrost Mechanisms

Consumer-grade freezers and many commercial units use automatic (frost-free) defrost cycles. These cycles rely on an internal heating element that periodically melts accumulated frost. The convenience is clear: users do not need to manually defrost. However, this convenience introduces temperature fluctuations inside the storage chamber. Each defrost cycle can cause the internal temperature to rise, even if momentarily, and such fluctuations can jeopardize sensitive materials.

Manual Defrost Advantages

In a laboratory or pharmacy setting, manual defrost freezers are often preferred precisely because they eliminate the temperature spikes associated with auto defrost cycles. Manual defrost units rely on the absence of forced airflow or internal heating cycles that would destabilize temperature. Although they require periodic manual defrosting, the stable, continuous low-temperature environment they provide is far more suitable for storing high-value, temperature-sensitive samples. Researchers must carefully plan defrost intervals, but the trade-off is unwavering temperature consistency.

No-Fan, More Stability

Manual defrost freezers often do not have internal fans, relying instead on cold wall technology. While this may reduce temperature uniformity to an extent, it also prevents forced-air circulation that could disturb open containers or cause sample drying. In many sensitive applications—such as storing certain reagents or biological samples in open containers—still air and stable conditions are critical.

The Risks of Using Consumer-Grade Freezers in a Lab Environment

Temperature Fluctuations and Sensitivity

One of the most significant risks of using a consumer-grade freezer is unpredictable temperature variability. While occasional fluctuations may not harm frozen foods, the same cannot be said for critical reagents or biological materials. Even small, short-term deviations can degrade enzymes, reduce vaccine potency, or alter the viability of cell cultures. Research results based on compromised samples can become skewed, leading to erroneous conclusions, wasted time, and increased costs.

Misleading Temperature Displays

Consumer units often feature a single thermostat dial with vague settings (e.g., “cold” to “coldest”) rather than precise digital temperature controls. Without precise control, you cannot ensure that all areas of the cabinet remain within the desired range. Moreover, the displayed temperature—often measured at a single point—may not reflect the actual temperature profile throughout the cabinet, resulting in hotspots or cold spots that damage sensitive materials.

Ambient Conditions and Door Openings

Laboratory and pharmacy environments are dynamic. Frequent door openings, routine sample loading, and higher ambient temperatures are commonplace. Consumer-grade models are not designed with these challenges in mind. They recover from temperature disturbances more slowly and can struggle to maintain stable conditions when heavily loaded or frequently accessed. Such instabilities can push internal temperatures outside critical thresholds, compromising sample integrity.

Regulatory Non-Compliance

Using non-certified refrigeration solutions also raises compliance issues. Many guidelines—such as the CDC’s vaccine storage recommendations and other regulatory standards—require highly stable and monitored storage conditions. Household units rarely meet these stringent regulatory and accreditation requirements. Non-compliance could lead to failed audits, loss of accreditation, and even potential legal ramifications.

Comparing Consumer-Grade Freezers with Purpose-Built Laboratory Units

Designed for Stringent Standards

Purpose-built laboratory refrigerators and freezers are specifically engineered and validated to meet the exacting demands of clinical and research environments. Unlike consumer units, they undergo rigorous testing using multiple open-air probes placed throughout the cabinet. For example, laboratory and pharmaceutical grade freezers have been validated to consistently maintain temperatures below –19°C at a –20°C setpoint under stable ambient conditions.

Real-World Performance

The difference is stark when you compare a properly validated laboratory freezer to a consumer-grade unit. Under similar conditions, a consumer-grade freezer might warm up to –14.9°C, surpassing the critical –15°C threshold needed for safe storage of many lab samples. This difference in performance underscores the fundamental design gulf between household and laboratory equipment.

Key Features for Stability

Laboratory grade freezers and pharmaceutical grade freezers often incorporate advanced features that improve reliability, such as thick foam insulation, robust cabinet construction, efficient compressors, and state-of-the-art microprocessor temperature controllers. Many models include digital LED displays, programmable logic controls for minimal temperature drift, and data logging capabilities to ensure long-term tracking of unit performance. These features collectively create a stable environment that preserves sample integrity and ensures reproducible research results.

Regulations, Guidelines, and Compliance

Adhering to Vaccine Storage Standards

Vaccine potency is particularly sensitive to temperature excursions. Guidelines set by the CDC and the Vaccines for Children (VFC) Program require refrigerators to maintain temperatures between 2°C and 8°C and freezers to maintain –15°C or colder. A household unit is simply not built for these rigorous standards. Using non-compliant equipment can lead to the loss of vaccine potency, forcing labs to discard costly supplies and potentially administer ineffective vaccines to patients.

Pharmaceutical and Biological Storage

For pharmaceuticals, blood, plasma, and other sensitive biologicals, precise temperature control is non-negotiable. Regulatory bodies, including the U.S. Food and Drug Administration (FDA), and various good manufacturing practices (GMP) inspections demand that equipment maintain tight temperature ranges, uniformity, and traceability. Laboratory-grade freezers and refrigerators meet these requirements by default and support features like continuous temperature monitoring, alarms, and data recording, which are essential for audit readiness.

Temperature Control, Monitoring, and Alarms

Precision Control Systems

Unlike a typical household unit with a simple internal dial, a laboratory refrigerator or freezer relies on microprocessor-based control systems that can maintain temperatures within a fraction of a degree. Sophisticated digital displays and programmable logic controls help ensure minimal drift and give technicians more control and insight.

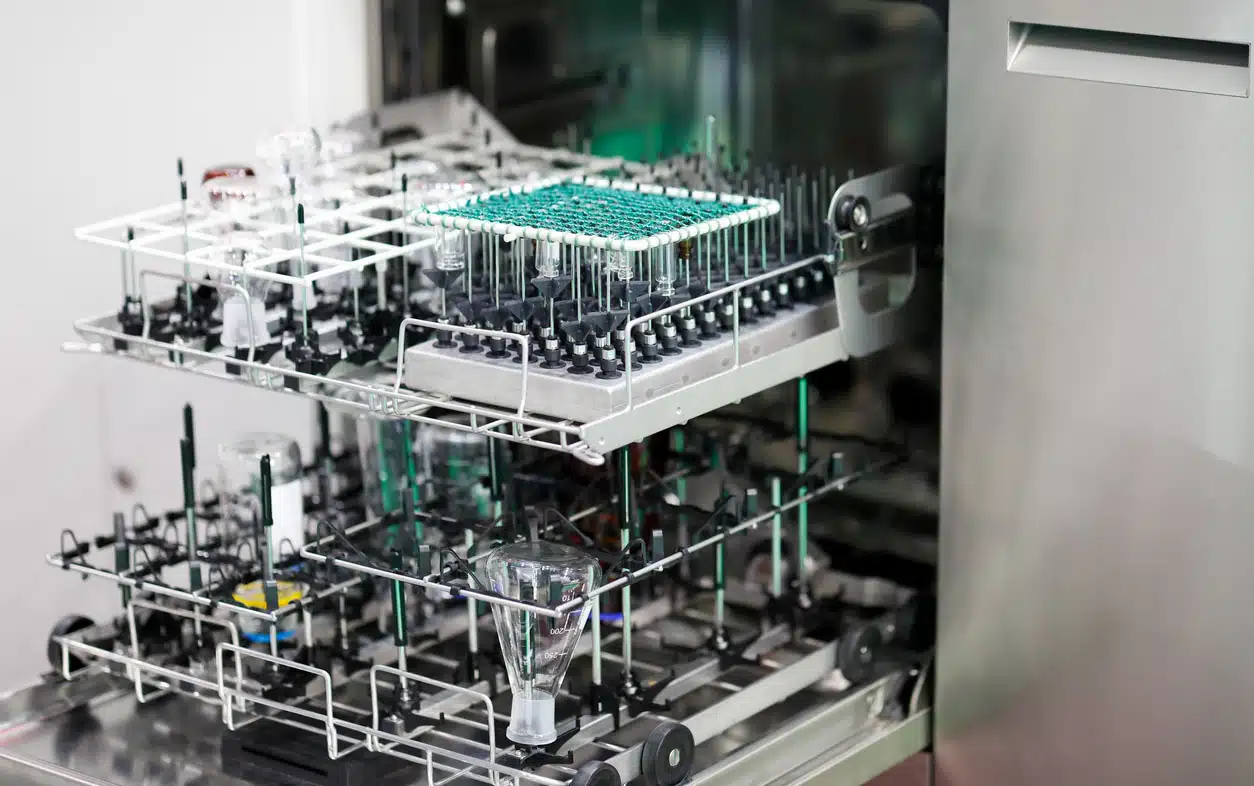

Monitoring and Record-Keeping

Manual record-keeping of temperature is still recommended twice daily by the CDC, even when automated alarming and data-logging systems are in place, as technology can fail. Many laboratory-grade units come with external temperature displays, alarm systems for out-of-range conditions, USB temperature data loggers, remote alarm contacts, and integration capabilities with laboratory information management systems (LIMS). These features make compliance with stringent record-keeping and auditing requirements more manageable.

Alarms and Fail-Safes

Modern laboratory refrigerators and freezers are equipped with both audible and visual alarms to warn personnel if the internal temperature drifts out of the set range. Some models connect to remote alarm contacts, alerting staff elsewhere in the facility. Glycol bottles often insulate temperature sensors to prevent false alarms triggered by transient events like door openings. These safety measures minimize risks and help catch problems before they compromise valuable samples.

Manual and Auto Defrost in Scientific Units

Auto-Defrost Scientific Models

Many laboratories do choose auto-defrost refrigerators and freezers when convenience and ease of maintenance are prioritized. Advanced auto-defrost models may allow users to control the frequency and duration of defrost cycles, coupled with strategies like loading the unit with water bottles to buffer temperature changes. While auto-defrost can be acceptable for some sample types, it may not be suitable for the most sensitive materials.

Manual-Defrost for Ultra-Sensitive Applications

Manual defrost units remain the gold standard for applications where even short-lived temperature fluctuations cannot be tolerated. Although manual defrosting requires planning and backup storage capacity, these units deliver consistent, stable temperatures critical for sensitive vaccines, enzymes, reagents, and biological samples. The trade-off in convenience is rewarded by uncompromising temperature stability.

Combination Units and Specialized Applications

Combination Refrigerator/Freezer Units

Space constraints and the need for both refrigeration and freezing capability might lead some labs to consider a combination unit. While a single-compressor, dual-chamber unit is convenient, it may struggle to maintain independent and tight temperature control in both sections. Units with separate compressors and thermostats for each compartment offer better reliability and uniformity, though at a higher cost. Ultimately, the decision depends on the sensitivity of the stored materials.

Specialty Refrigerators: Flammable and Hazardous Materials

Laboratories storing flammable or explosive materials must consider explosion-proof or flammable storage units. These specialized models isolate or completely seal electrical components to prevent sparks. They meet strict National Fire Protection Association (NFPA) and Occupational Safety and Health Administration (OSHA) guidelines. No household refrigerator can offer this level of safety assurance or compliance.

Where to Place Your Lab Refrigerator or Freezer

Spatial Considerations

Before purchasing any laboratory refrigerator or freezer, consider the available space carefully. Will the unit fit through doors and into designated areas? Undercounter models differ from freestanding models in their ventilation needs. Ventilation clearance requirements vary by manufacturer and model, and ignoring them can lead to reduced efficiency and performance issues.

Environmental Factors

Avoid placing lab refrigerators and freezers near heating vents, in direct sunlight, or in areas of heavy foot traffic. Such conditions can cause unnecessary temperature fluctuations and increase energy consumption. Careful placement helps maintain the ideal environment for stable operation.

Optional Equipment and Customization

Doors, Shelves, and Storage Configurations

Laboratory refrigerators and freezers come with various customization options:

- Glass vs. Solid Doors: Glass doors allow quick visual inspection of contents without opening the door, minimizing temperature disturbance. Solid doors provide better insulation and may be preferable for sensitive storage.

- Drawers vs. Shelving: Some units offer drawers or baskets that ease sample organization. Adjustable shelves let you optimize storage space.

- Door Locks and Security Systems: If you store high-value or controlled substances, locks and alarm systems provide added security and regulatory compliance.

- Stainless Steel Interiors and Exteriors: Durable and easy to clean, stainless steel surfaces suit environments demanding strict hygiene.

- Sensor Ports and Internal Electrical Outlets: These facilitate installing temperature sensors, data loggers, or other scientific equipment inside the unit without damaging the sealed environment.

Energy Efficiency and Sustainability

Energy Consumption

Laboratory and pharmacy refrigerators and freezers often run continuously, making energy efficiency a critical consideration. ENERGY STAR®-rated units incorporate efficient compressors, eco-friendly refrigerants, and microprocessor-based controllers that reduce power consumption. Investing in an energy-efficient model not only lowers utility costs but also reduces the lab’s environmental footprint.

Advanced Refrigerants and Refrigeration Technology

Some advanced models adapt compressor speed to cooling demand, enhancing temperature stability and cutting energy use. Such state-of-the-art systems reflect a growing industry trend towards sustainable, high-performance refrigeration solutions.

Choosing the Right Supplier and Manufacturer

Quality, Support, and Reputation

When selecting laboratory refrigeration equipment and pharmacy refrigeration equipment, consider the manufacturer’s track record, support services, and warranty terms. Established brands bring a wealth of expertise, innovation, and reliability. Working with a reputable supplier ensures you receive guidance in selecting the right model, have access to technical support, and can rely on timely service and maintenance.

Tailor-Made Solutions for Your Lab

No two laboratories are identical. A trusted manufacturer or supplier can help you navigate the maze of temperature ranges, features, certifications, and optional components to find the perfect unit. Whether you need a high-capacity –86°C ultra-low temperature freezer, a 2–8°C refrigerator for vaccines, or explosion-proof storage for flammable reagents, specialized vendors can guide your purchase.

Conclusion: Ensuring the Integrity of Your Research and Clinical Work

The investment in a laboratory-grade refrigerator or freezer is not simply about purchasing a piece of equipment—it is about protecting the integrity of your research, the validity of your results, and, ultimately, the health and safety of patients who may rely on the outcomes of your work. While consumer-grade freezers may appear more economical initially, their hidden risks—temperature instability, lack of compliance, insufficient monitoring, and long-term damage to samples—far outweigh any short-term cost savings.

By choosing a purpose-built, laboratory-grade refrigerator or manual defrost freezer, you gain consistent temperature performance, robust alarm systems, thorough documentation, and compliance with regulatory standards. Such an investment not only enhances the reliability of your current projects but safeguards your laboratory’s or pharmacy’s reputation, credibility, and success moving forward.

Continuing the Exploration of Purpose-Built Laboratory Cold Storage Solutions

As previously discussed, selecting purpose-built laboratory refrigerators and freezers—rather than relying on consumer-grade equipment—ensures stable, compliant, and secure environments for temperature-sensitive materials. Now, let’s examine a series of laboratory refrigeration and freezing units developed and distributed by ARES Scientific, a company dedicated to providing innovative and reliable cold storage solutions. By reviewing their features, you can see how these models align seamlessly with the principles outlined above, delivering the precise temperature control, eco-conscious operation, and robust security measures that clinical, research, and pharmaceutical professionals require.

Precision Temperature Control for Consistency and Compliance

A key differentiator of ARES Scientific’s laboratory-grade units is their microprocessor-based temperature management systems. For instance, the ARS-HC-SSP-23 single swing solid door stainless steel laboratory refrigerator maintains temperatures between 1°C and 10°C with a digital display for at-a-glance readings. This level of precise control ensures that reagents, vaccines, and sensitive biological samples remain within the narrow temperature tolerances demanded by regulatory guidelines and best practices—an assurance no standard household freezer can guarantee.

Other models, including upright glass door configurations or larger-capacity double-door units, follow similar protocols. Their microprocessor controllers and strategically placed temperature probes minimize deviations from setpoints. High and low-temperature alarms, which alert users to any temperature excursion, allow laboratory personnel to act swiftly, preserving sample integrity and ensuring compliance with standards set by organizations such as the CDC.

Eco-Friendly Refrigeration and Sustainable Operation

ARES Scientific’s refrigeration lineup prioritizes environmental responsibility without sacrificing performance. Many models use natural hydrocarbon refrigerants like R290 or R600a, which reduce global warming potential and meet EPA and SNAP guidelines. This approach balances exceptional cooling efficiency with reduced environmental impact, showing that laboratory refrigeration can and should be both high-performing and eco-friendly.

From compact undercounter units to large 49 cu. ft. refrigerators, ARES Scientific’s equipment exemplifies how sustainable design considerations can be integrated into laboratory environments. In doing so, these products go beyond regulatory compliance, supporting a more sustainable future for scientific research and healthcare operations.

Security Features and Alarm Capabilities

Security is paramount when storing expensive, rare, or potentially life-saving materials. ARES Scientific’s laboratory refrigerators and freezers incorporate keyed door locks to prevent unauthorized access, while integrated alarm systems—both audible and visual—keep staff informed of any unacceptable temperature deviations. Remote alarm contacts extend this vigilance beyond the physical lab, allowing off-site personnel or facility management systems to receive alerts in real-time.

Such comprehensive security measures embody the difference between purpose-built equipment and consumer-grade appliances. Laboratories demand not just cooling but a holistic safeguarding system for their critical inventory. ARES Scientific meets these demands head-on, enhancing user confidence and peace of mind.

Durable Construction for Long-Term Reliability

Another standout feature of ARES Scientific’s refrigeration products is their robust construction. High-density urethane foam insulation, stainless steel exteriors, and heavy-duty hinges are common design elements across various models. This ensures that units withstand frequent door openings, variable ambient conditions, and the daily challenges of a busy laboratory environment.

Long-term durability is not merely about sturdiness; it also supports stable temperature environments. By preventing temperature stratification and reducing susceptibility to external heat loads, well-constructed units maintain more consistent internal conditions. Over time, this contributes to better sample preservation and a lower total cost of ownership—yet another reason labs prefer dedicated laboratory equipment over consumer-grade units.

Flexible Configurations and Specialized Options

From manual to auto defrost, glass to solid doors, and capacities ranging from undercounter sizes to large-volume double-door units, ARES Scientific’s product portfolio ensures that each laboratory can find the right unit for its unique requirements.

For example, controlled auto defrost (CAD) technology in certain models precisely times the defrost cycle to maintain stable conditions, catering to materials that cannot tolerate even minor warming events. Meanwhile, manual defrost models offer unwavering temperature consistency, crucial for extremely sensitive applications. This variety ensures that no matter how specialized or demanding your storage needs are, there’s an ARES Scientific unit designed to meet them.

Undercounter and Specialty Units for Space-Saving Efficiency

Space constraints are a reality in many laboratories and clinical facilities. ARES Scientific addresses this by offering undercounter and built-in models that integrate seamlessly into existing cabinetry, freeing up valuable floor space. Specialty units, including controlled room temperature (CRT) cabinets and combination refrigerator/freezer units, further expand the range of available solutions.

By providing storage solutions that adapt to your space and operational needs, ARES Scientific demonstrates a commitment to enabling more efficient, organized, and productive laboratories. This emphasis on adaptability stands in stark contrast to the limited options offered by standard home refrigeration units.

The features of ARES Scientific’s laboratory refrigerators and freezers—precise temperature control, eco-friendly refrigerants, integrated alarms, durable construction, and a wide array of configurations—perfectly mirror the earlier arguments against using consumer-grade appliances. By investing in purpose-built equipment, laboratories gain the reliability and performance needed to maintain sample integrity, ensure regulatory compliance, and preserve valuable research assets.

Not only do these products minimize the risk of costly sample loss and experimental inconsistencies, but they also provide peace of mind. Laboratory personnel, facility managers, and quality assurance teams can trust that their cold storage infrastructure is up to the task, every day and every hour.

At the end of the day, your laboratory’s success hinges on the integrity of your temperature-sensitive materials. Ensuring that they remain stable, secure, and readily accessible starts with the right cold storage solutions. By choosing ARES Scientific as your trusted refrigeration expert and partner, you’re investing in more than just top-quality equipment—you’re gaining access to a team of specialists who are dedicated to guiding you through every step, from product selection and installation to ongoing support and maintenance. Our extensive knowledge, robust product portfolio, and unwavering commitment to excellence mean you’ll receive the personalized solutions and reliable service you deserve.

Don’t leave the integrity of your critical samples to chance. Reach out to ARES Scientific today, and let us show you how our innovative laboratory refrigerators and freezers can elevate the quality, precision, and sustainability of your cold storage operations. Our team of experts is ready to help you find the perfect fit for your unique requirements, ensuring that the future of your lab remains bright, productive, and secure.