Research vivariums serve as vital hubs where animals are nurtured and studied to push the boundaries of scientific inquiry and medical advancements. These specialized facilities are essential for conducting controlled experiments, observing animal behavior, and developing new treatments. Ensuring that these environments maintain optimal conditions is paramount, not only for the welfare of the animals but also for the integrity of the research conducted within.

As the complexity and scale of research evolve, so too does the need for innovative solutions to manage these intricate environments efficiently. Automation represents a pivotal advancement in the management of research vivariums. Transitioning from simple mechanized tools to sophisticated, interconnected systems, automation today offers a promise of unparalleled precision, efficiency, and reliability in animal care and data management.

The importance of automation in vivariums cannot be overstated. With growing pressures to enhance efficiency, reduce costs, and comply with stringent regulatory standards, more facilities are turning to automation technology. From automated feeding systems to intricate environmental controls and data management solutions, these technologies are revolutionizing how vivariums operate, leading to better animal welfare, more accurate research outcomes, and more sustainable operations overall.

This guide will explore the various aspects and benefits of automation in vivariums, delving into how these technologies are addressing current challenges and transforming the landscape of scientific research facilities. Whether it’s through enhancing the precision of environmental conditions, reducing the labor intensity of daily tasks, or integrating advanced data analysis tools, automation stands at the forefront of modernizing research vivariums, paving the way for more humane and effective scientific exploration.

Addressing the Technician Shortage: Automation in Vivariums

Challenges in Attracting and Retaining Technicians

Animal care technicians are often unsung heroes in vivaria and animal-related research. However, attracting and retaining these professionals is becoming increasingly challenging. Many workers find the job’s low pay and repetitive nature unappealing, creating a significant gap in the workforce.

Role of Automation in Bridging the Gap

Emerging research is exploring whether automating low-level tasks can help bridge this gap while potentially enhancing the quality of life for the animals. Automation can take over repetitive tasks, allowing technicians to focus on more complex and meaningful activities, improving job satisfaction and retention.

Types of Automation Technologies in Vivariums

Environmental Control Systems

Automation in environmental control involves regulating temperature, humidity, and lighting. Automated systems ensure these parameters remain within optimal ranges, creating a stable environment supporting animal health and well-being.

Animal Monitoring and Tracking

Technologies such as RFID and microchips are used to monitor and track animals. Automated health monitoring systems can detect changes in behavior, weight, and activity levels, allowing for early intervention and better animal welfare management.

Feeding and Watering Systems

Automated feeders and watering systems provide consistent and precise amounts of food and water to animals. These systems reduce the risk of human error and ensure that animals receive the necessary nutrients and hydration at regular intervals.

Data Management and Analysis

Software tools for data collection and analysis are integral to automation in vivariums. These tools enable researchers to gather, store, and analyze large volumes of data efficiently. Integration with research databases facilitates comprehensive data analysis and reporting.

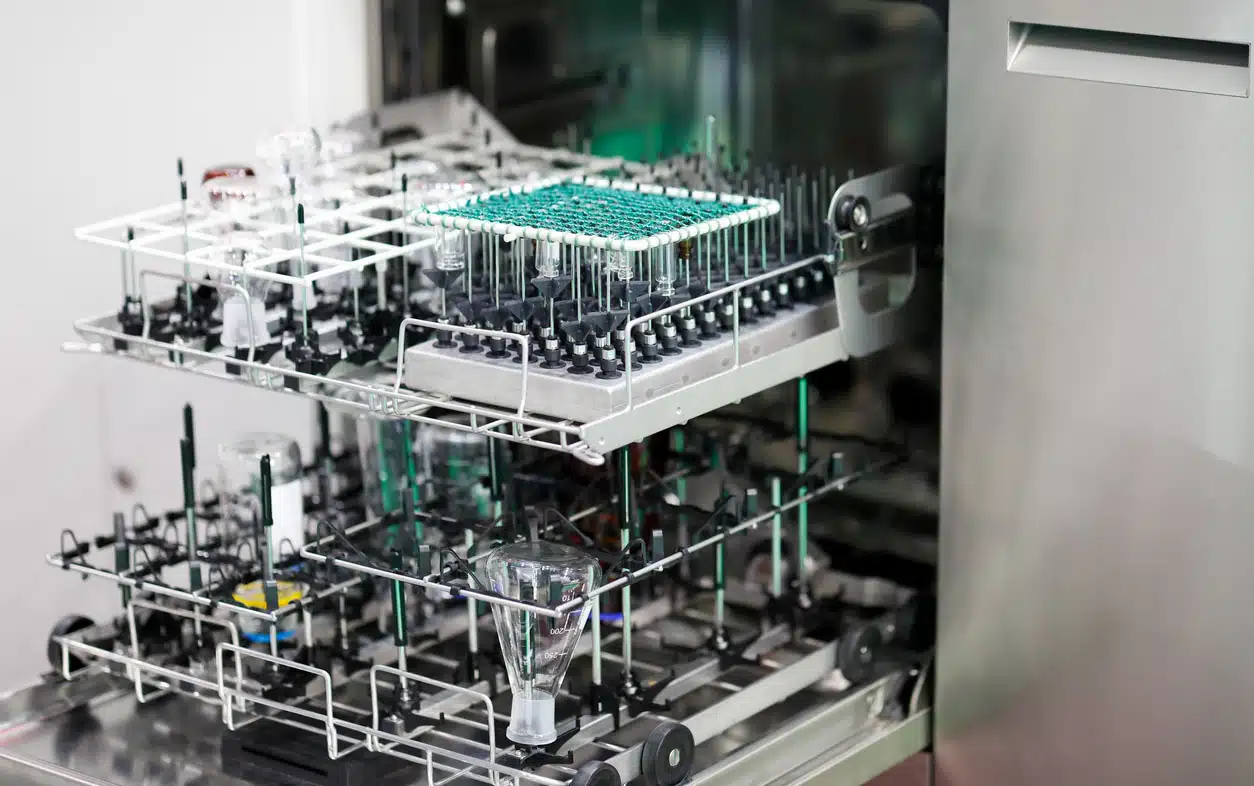

Automatic Cage and Rack Washing Systems

Automatic cage and rack washing systems significantly enhance operational efficiency in vivariums. These systems ensure thorough cleaning and sterilization of cages and racks, reducing the risk of contamination and infection. Automated washers can handle large volumes, allowing technicians to focus on other critical tasks.

Automatic Tank Washing Systems for Aquatics Research

Automatic tank washing systems are particularly beneficial for aquatics research, such as Zebrafish studies. These systems ensure that tanks are cleaned and disinfected regularly, maintaining a healthy environment for aquatic species and minimizing disease risk.

Automatic Cage Changing Systems

Automatic cage-changing systems streamline the process of changing animal cages, reducing the need for manual labor and minimizing animal stress. These systems ensure that animals are moved to clean cages efficiently and safely.

Automatic Bedding Disposal Systems

Automatic bedding disposal systems enhance hygiene and efficiency in vivariums by automating the disposal of soiled bedding. These systems reduce the manual handling of waste, improve sanitation, and reduce the risk of contamination.

Benefits of Automation in Vivariums

Improved Animal Welfare

Automation ensures consistent and optimal living conditions for animals, reducing stress and improving overall health. Automated systems minimize human error and ensure that animals receive consistent care.

Enhanced Research Accuracy and Efficiency

Automated data collection and monitoring improve the accuracy and reliability of research. These technologies enable researchers to gather precise data and increase the reproducibility of experiments.

Operational Efficiency

Automation saves time for vivarium staff by automating routine tasks. This efficiency translates into cost savings and allows staff to focus on more complex and critical tasks.

Compliance and Standardization

Automated systems help vivariums meet regulatory standards by maintaining consistent conditions and detailed records. Standardized procedures ensure that experiments are conducted uniformly, supporting compliance and quality assurance.

Reducing Throughput

A. Optimization Through Data Gathering and Analysis

Data gathering and analysis offer a path to optimization for facilities not yet ready for full-scale automation. Facilities can make significant improvements by focusing on tasks that directly benefit animal well-being and research quality. For instance, a case study demonstrated that by washing only genuinely soiled cages, a lab could save substantial costs and reallocate human resources more efficiently.

B. Financial and Operational Impact

This approach highlights the potential for automation to reduce operational costs and improve task allocation without compromising cleanliness and animal care. Optimizing throughput can lead to significant savings and better resource management.

Enhancing Animal Wellbeing

Less Stressful Environments

Automating routine tasks can also lead to less stressful environments for the animals. Reducing human interaction and handling can minimize stress-induced variations in research data.

Robotic Automation and Non-Intrusive Monitoring

By incorporating robotic automation and non-intrusive monitoring technologies, facilities can maintain a stable and less disruptive environment for the animals. This balance between technology and animal care promises to improve both the quality of research outcomes and the well-being of the animals.

Automated Watering Systems

System Comparisons

- Recirculation Systems: Uses less water but more energy due to continuous pump operation.

- Flushing Systems: Uses more water but less energy and can operate with city water supply pressure during an electric utility failure.

- Hybrid Systems: Combines features of both recirculation and flushing systems, optimizing water and energy use.

Future Trends and Innovations

Advances in AI and Machine Learning

AI and machine learning technologies can enhance predictive analytics for animal health, allowing for early detection of potential issues. These technologies also improve data processing capabilities, making it easier to analyze large datasets.

Internet of Things (IoT) in Vivariums

IoT devices like intelligent cages and equipment enable real-time monitoring and alerts. These devices provide continuous data on animal conditions and environmental parameters, facilitating immediate responses to deviations.

Potential for Personalized Animal Care

Automation technologies can be tailored to provide customizable environments for individual animals. Personalized health monitoring and care plans improve the overall well-being of animals and support specific research needs.

Embracing Laboratory Automation

Enhancing Productivity and Safety

Laboratory automation is doing amazing things, from reducing the risk of injury to building more efficient processes. Integrating automation in vivarium labs is not just about keeping up with technology; it’s about enhancing productivity, safety, and research quality.

The Necessity of Investment

Many lab animal research facilities hesitate to adopt automation due to the high costs, which range from $500,000 to $2.5 million. However, the investment pays off in the long run. For instance, automated systems like a cart system streamline the process of cleaning and transporting cages, saving technicians hours of time and ensuring more sanitary conditions.

Benefits of Automation

- Error Reduction: Up to 86% error reduction compared to manual processes.

- Speed: Automated processes are typically 60% faster than manual ones.

- Cost Savings: Automated systems help save on wasted materials and damaged equipment.

A Phased Approach to Automation

Smaller facilities can start with processes that offer the most significant benefits and gradually build upon their automation systems. Partnering with workflow consultants and automation professionals can help tailor solutions to specific needs, ensuring a smooth transition.

Automated Watering Solutions for Rodent Housing

Animal Care Systems is a leading provider of innovative solutions designed to enhance the efficiency and reliability of rodent housing management. Their automated watering systems are specifically tailored to meet the unique needs of rodent housing environments, bringing several key benefits that significantly improve animal welfare and streamline vivarium operations.

Consistent and Reliable Water Supply

Animal Care Systems‘ automated watering solutions ensure rodents receive a constant, reliable, clean water supply. This consistency is crucial for maintaining the animals’ health and well-being, eliminating the variability and potential for human error associated with manual watering methods. The automated systems deliver water at the right pressure and volume, tailored to the specific requirements of rodent species.

Key Products and Features

One notable product in Animal Care Systems’ lineup is the Edstrom Quick Disconnect Watering Valve. This valve is designed for ease of use and reliability, featuring a quick-disconnect mechanism that simplifies connecting and disconnecting water lines. This highly efficient system ensures that each rodent cage receives a steady water flow without the risk of leaks or blockages.

Another innovative automated watering system is featured on the new products page. These systems are designed with user-friendly features that make them easy to install and maintain, ensuring seamless integration into any vivarium setup. Key features include:

-

Reliable Water Delivery: Automated systems provide a steady flow of water at the correct pressure, tailored to the specific needs of rodents, ensuring consistent hydration.

-

Ease of Maintenance: Quick-connect and disconnect mechanisms simplify routine maintenance and address any issues without disrupting the water supply.

-

Advanced Monitoring: Systems equipped with monitoring capabilities track water usage and detect potential issues such as leaks or blockages. Real-time alerts ensure problems are promptly addressed, maintaining uninterrupted water delivery.

Enhanced Monitoring and Maintenance

These automated watering systems are equipped with advanced monitoring capabilities. They can track water usage, detect potential leaks, and provide real-time alerts to staff if any issues arise. This proactive approach to maintenance ensures that problems are addressed promptly, minimizing downtime and ensuring animals always have access to fresh water.

Improved Hygiene and Safety

Automated watering solutions prioritize hygiene and safety. The closed-system design reduces the risk of contamination, a common concern with traditional watering methods. This helps prevent the spread of diseases and infections, contributing to a healthier living environment for rodents. Some systems are also designed to be self-cleaning, further enhancing the hygiene and safety of the water supply.

Labor and Cost Efficiency

Automated systems streamline the watering process, reducing the labor required for daily maintenance tasks. This allows vivarium staff to focus on other essential duties, enhancing operational efficiency. Additionally, these systems are more resource-efficient, reducing water wastage and lowering operational costs over time.

Steelco Cage and Rack Washers: Enhancing Vivarium Automation

Steelco Cage and Rack Washers are at the forefront of vivarium automation and are designed to meet the stringent cleaning and sanitation requirements of research facilities while streamlining operations through advanced features. Here’s how Steelco Cage and Rack Washers support vivarium automation:

- Automated Cleaning Cycles: Steelco washers offer fully automated cleaning cycles that can be programmed to handle various cage and rack configurations. This flexibility reduces the need for manual intervention, allowing staff to focus on more critical tasks.

- Advanced Control System: Steelco washers are equipped with an intuitive touch-screen interface, which allows users to easily set and monitor washing parameters. This user-friendly system ensures precise control over the washing process, enhancing efficiency and consistency.

- Efficient Water and Energy Use: Designed to optimize water and energy consumption, Steelco washers feature multiple cycle options that adjust resource use based on the load’s requirements. This not only supports sustainability goals but also reduces operational costs.

- High Throughput Capacity: With their large chambers and robust designs, Steelco washers can handle high volumes of cages and racks, making them ideal for large vivariums with significant daily cleaning needs. This high throughput capacity ensures that even the most demanding facilities can maintain a consistent workflow.

- Reliable Performance and Maintenance: Steelco washers are built for durability and ease of maintenance. Automated self-diagnosis features alert users to potential issues before they become problematic, ensuring minimal downtime and reliable performance.

- Integration with Vivarium Management Systems: Steelco washers can be integrated with broader vivarium management systems, enabling seamless coordination with other automated processes within the facility. This integration ensures that cage and rack cleaning schedules are synchronized with animal care routines, promoting a well-organized and efficient operation.

Automation of Zebrafish and Aquatics Tank Washing: Steelco and Miele

Automating tank washing for zebrafish and other aquatic research subjects significantly advances laboratory efficiency and consistency. Brands like Steelco and Miele are leading the way with their innovative solutions, transforming what has traditionally been a manual process into an automated one. Here’s how their technologies support the automation of zebrafish and aquatics tank washing:

- Automated Cleaning Cycles: Both Steelco and Miele offer tank washers with fully automated cleaning cycles. These systems can be programmed to handle various tank sizes and types, reducing the need for manual scrubbing and ensuring thorough cleaning every time.

- Advanced Control Systems: These washers feature intuitive control interfaces, allowing users to easily set and monitor cleaning parameters. This precision ensures that each tank is cleaned according to specific requirements, enhancing efficiency and reproducibility in research environments.

- Optimized Resource Use: Steelco and Miele washers are designed to optimize water and energy usage. By adjusting resource consumption based on the load, these systems support sustainability initiatives and help lower operational costs.

- High Capacity and Throughput: Steelco and Miele washers’ robust designs accommodate large tank volumes, making them suitable for large-scale research facilities. Their high throughput capacities ensure that even the busiest labs can maintain a steady workflow without bottlenecks.

- Reliable Performance and Easy Maintenance: Built for durability, these washers feature automated self-diagnosis systems that alert users to potential issues before they escalate. This reliability minimizes downtime and maintenance needs, ensuring continuous operation.

- Integration with Laboratory Management Systems: Both brands offer solutions that can be integrated with broader laboratory management systems. This capability allows seamless coordination with other automated processes, ensuring tank washing schedules align with overall lab workflows and research activities.

- Consistent Cleaning Quality: Automation ensures consistency, which is hard to achieve with manual washing. Every tank undergoes a standardized cleaning process, which is critical for maintaining the health and well-being of zebrafish and other aquatic subjects.

SychemWASTE: Automating Bedding Disposal

SychemWASTE is revolutionizing bedding disposal in vivariums through its advanced automation capabilities, providing a more efficient, hygienic, and ergonomic solution for laboratory staff. Here’s how SychemWASTE supports the automation of bedding disposal:

- Automated Bedding Disposal Process: SychemWASTE features a fully automated disposal system that significantly reduces the manual handling of soiled bedding. This automation minimizes staff exposure to allergens and contaminants, enhancing workplace safety.

- Touch-Screen Control Panel: The intuitive touch-screen control panel allows users to operate the system easily and adjust settings to match specific bedding disposal needs. This user-friendly interface ensures the process is simple and efficient, requiring minimal training.

- Enhanced Ergonomics: The design of the automated bedding disposal system focuses on enhancing lab personnel ergonomics by minimizing physical strain. This system automates the labor-intensive tasks of handling and disposing of bedding, thereby enabling staff to work in greater comfort and reducing their risk of injury.

- Integrated Dust Extraction: An advanced dust extraction system is incorporated within SychemWASTE to maintain a clean working environment. This feature effectively captures and removes airborne particles during bedding disposal, ensuring that air quality remains high.

- Efficiency and Time Savings: By automating the bedding disposal process, SychemWASTE drastically reduces the time required for this task. This efficiency allows laboratory staff to allocate more time to critical research activities, enhancing overall productivity.

- Sustainability Features: Designed with sustainability in mind, SychemWASTE optimizes resource use and minimizes waste. This system supports green initiatives within the laboratory, contributing to more environmentally responsible operations.

- Customizable Settings: The flexibility of SychemWASTE allows for customizable settings to accommodate different types of bedding and animal housing configurations. This adaptability ensures that the system can meet the unique needs of various research facilities.

Incorporating SychemWASTE into your vivarium enhances bedding disposal automation and promotes a safer, more efficient, and sustainable working environment. This innovation allows laboratory staff to focus more on their research while maintaining high hygiene and ergonomics standards.

SychemFILL: Automating Bedding Dispensing

SychemFILL is transforming how bedding is dispensed in vivariums, offering an automated solution that enhances efficiency, accuracy, and hygiene. Here’s how SychemFILL supports the automation of bedding dispensing:

- Automated Bedding Dispensing: SychemFILL automates the dispensing process, ensuring a consistent and accurate distribution of bedding into cages. This automation eliminates the variability and labor-intensive nature of manual bedding filling, improving overall workflow efficiency.

- Precision and Consistency: Equipped with advanced sensors and controls, SychemFILL guarantees precise bedding measurements for each cage. This consistency is crucial for maintaining uniform conditions across all animal habitats, supporting reliable research outcomes.

- User-Friendly Interface: The system features an intuitive control panel that allows users to set and monitor dispensing parameters easily. This user-friendly interface ensures that staff can operate the system with minimal training, streamlining the bedding dispensing process.

- Ergonomic Design: SychemFILL is designed to reduce the physical strain associated with manual bedding filling. By automating this task, the system helps to prevent repetitive strain injuries and enhances the overall ergonomics of laboratory personnel.

- Dust Control: To maintain a clean and healthy working environment, SychemFILL incorporates dust control mechanisms. These features effectively capture and contain dust particles generated during dispensing, ensuring better air quality and reducing allergen exposure.

- Time and Labor Savings: Automating the bedding dispensing process with SychemFILL significantly reduces the time and labor required for this routine task. This efficiency allows laboratory staff to focus more on critical research activities, boosting productivity.

- Sustainable Operations: SychemFILL is designed to optimize resource use and minimize waste, supporting sustainable practices within the laboratory. This system helps reduce the environmental footprint of vivarium operations while maintaining high standards of animal care.

- Customizable Settings: The system offers customizable settings to accommodate different types of bedding materials and cage sizes. This adaptability ensures that SychemFILL can meet the diverse needs of various research facilities.

Unlocking Efficiency and Enhancing Animal Welfare with ARES Scientific: Your Strategic Partner in Vivarium Automation

In conclusion, ARES Scientific emerges as a pivotal ally and expert in vivarium automation, providing comprehensive and cutting-edge solutions that redefine efficiency and welfare in research vivariums. By aligning with premier brands at the forefront of automation technology, ARES ensures that facilities are equipped with the best tools to enhance animal welfare and the integrity and reproducibility of scientific research.

ARES Scientific’s extensive portfolio includes brands like Animal Care Systems, Steelco, Sychem, and Miele. Each contributes unique automation solutions that address specific aspects of vivarium operations. From advanced watering systems to sophisticated bedding management and washing systems, these innovations streamline processes, reduce manual labor, and improve the environment for animals and staff.

Choosing ARES Scientific as your partner in vivarium automation means investing in reliability and expertise. ARES stands out for its commitment to quality and customer service, providing tailored solutions that fit the unique needs of each research facility. Their deep understanding of the challenges faced by vivariums allows them to offer not just products but holistic solutions that integrate seamlessly into existing workflows, enhancing productivity and ensuring compliance with the highest standards of animal welfare and research ethics.

Moreover, ARES’s approach to customer collaboration is not just about providing equipment but also about offering ongoing support, training, and consultancy. This ensures that each installation of automation technology is maximized for optimal performance, longevity, and adaptability to future advancements in research needs.

In a rapidly evolving field where precision and efficiency are paramount, partnering with ARES Scientific guarantees access to the forefront of automation technology, where the welfare of animals and the quality of research outcomes are elevated through thoughtful innovation and technological prowess. ARES is not merely a supplier; it is a strategic partner driving progress in the scientific community.